Liquid-level-checker

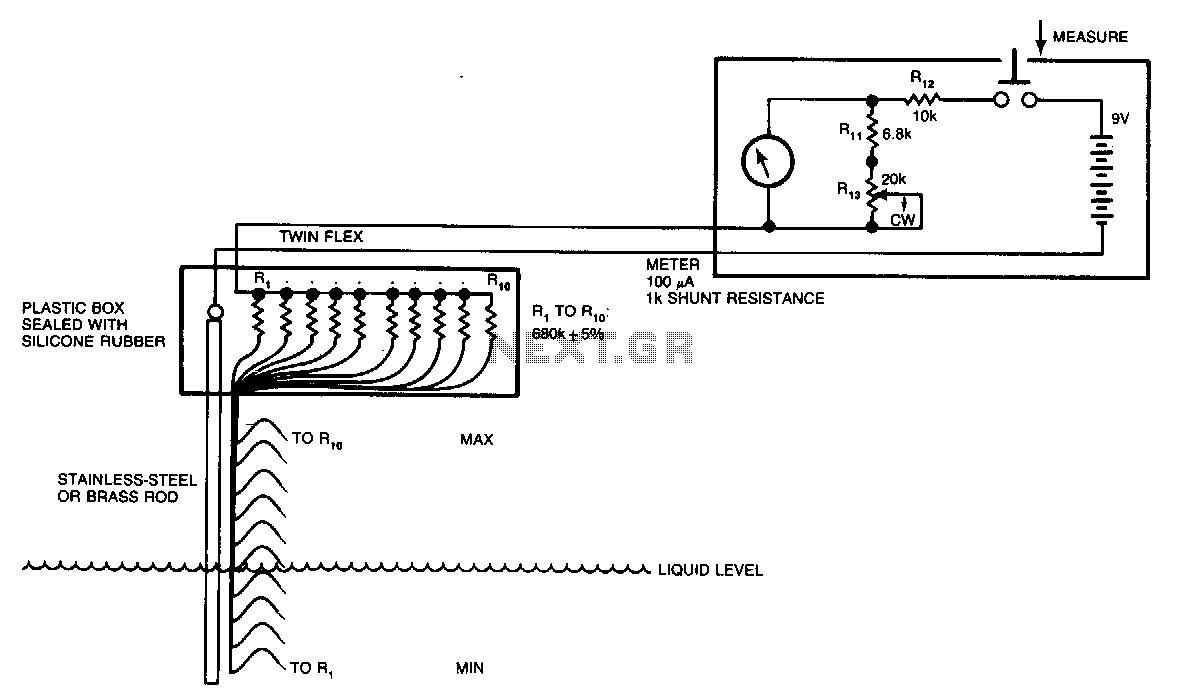

Although many circuits utilize the varying-capacitance method for measuring liquid levels, this straightforward resistive circuit is significantly easier to construct. Even a tank containing a liquid, such as water, has sufficient conductive salts in solution for this method to function effectively. The probe consists of a metal rod that supports ten insulated wires, which have stripped ends facing downward. As the liquid level rises, resistors R1 through R10 are sequentially included in the circuit, each drawing an additional 10 µA through the meter. Shunt resistors R11 and R13 are used to calibrate the meter for a full-scale reading when the tank is full. Resistor R12 limits the current flowing through the meter. If the tank is not rectangular—meaning the volume of the liquid it contains is not directly proportional to the liquid's depth—space the resistors accordingly or utilize a nonlinear progression of resistor values while maintaining constant resistor spacing.

This resistive liquid level sensing circuit offers a practical solution for monitoring liquid levels in various applications. The core component of the system is the probe, which is designed to be inserted into the liquid tank. The metal rod serves as the main sensing element, while the ten insulated wires, with their stripped ends, provide contact points at different depths within the tank.

As the liquid rises, it successively engages the resistors R1 through R10, effectively increasing the total resistance in the circuit and allowing for a precise measurement of the liquid level based on the current drawn by the meter. Each resistor contributes a specific increment of current (10 µA), facilitating a linear response that can be easily interpreted on the meter.

The inclusion of shunt resistors R11 and R13 plays a critical role in the calibration process. These resistors are strategically placed to ensure that when the tank is full, the meter reads at its maximum scale. This calibration is essential for accurate liquid level readings, allowing for adjustments based on the specific characteristics of the tank and the liquid being measured.

In cases where the tank does not have a uniform shape—such as cylindrical or irregular forms—the relationship between liquid depth and volume changes. To accommodate this, it may be necessary to adjust the spacing of the resistors or to select a nonlinear progression of resistor values. This adaptability ensures that the circuit remains effective across different tank designs and liquid types, providing reliable liquid level monitoring in a variety of settings.

Overall, this resistive circuit design is not only simple to implement but also versatile, making it suitable for a range of liquid level sensing applications in both industrial and domestic environments.Although many circuits use the varying-capacitance method for checking liquid levels, this simple resistive circuit is much easier to construct. Even a tank of a liquid, such as water, has sufficient conductive salts in solution for this method to work.

The probe uses a metal rod that supports 10 insulated wires, which have stripped ends pointing down. As the level of liquid rises, resistors Rl through Rl0 are successively brought into circuit, each drawing an extra 10 p.A through the meter.

Shunt resistors Rll and R13 calibrate the meter for a full-scale reading when the tank is full. Resistor R12 limits the current through the meter. If tank isn"t rectangular-ie, if the volume of the liquid it contains isn"t directly proportional to the liquid"s depth-space the resistors accordingly or use a nonlinear progression of resistor values and retain constant resistor spacing.

This resistive liquid level sensing circuit offers a practical solution for monitoring liquid levels in various applications. The core component of the system is the probe, which is designed to be inserted into the liquid tank. The metal rod serves as the main sensing element, while the ten insulated wires, with their stripped ends, provide contact points at different depths within the tank.

As the liquid rises, it successively engages the resistors R1 through R10, effectively increasing the total resistance in the circuit and allowing for a precise measurement of the liquid level based on the current drawn by the meter. Each resistor contributes a specific increment of current (10 µA), facilitating a linear response that can be easily interpreted on the meter.

The inclusion of shunt resistors R11 and R13 plays a critical role in the calibration process. These resistors are strategically placed to ensure that when the tank is full, the meter reads at its maximum scale. This calibration is essential for accurate liquid level readings, allowing for adjustments based on the specific characteristics of the tank and the liquid being measured.

In cases where the tank does not have a uniform shape—such as cylindrical or irregular forms—the relationship between liquid depth and volume changes. To accommodate this, it may be necessary to adjust the spacing of the resistors or to select a nonlinear progression of resistor values. This adaptability ensures that the circuit remains effective across different tank designs and liquid types, providing reliable liquid level monitoring in a variety of settings.

Overall, this resistive circuit design is not only simple to implement but also versatile, making it suitable for a range of liquid level sensing applications in both industrial and domestic environments.Although many circuits use the varying-capacitance method for checking liquid levels, this simple resistive circuit is much easier to construct. Even a tank of a liquid, such as water, has sufficient conductive salts in solution for this method to work.

The probe uses a metal rod that supports 10 insulated wires, which have stripped ends pointing down. As the level of liquid rises, resistors Rl through Rl0 are successively brought into circuit, each drawing an extra 10 p.A through the meter.

Shunt resistors Rll and R13 calibrate the meter for a full-scale reading when the tank is full. Resistor R12 limits the current through the meter. If tank isn"t rectangular-ie, if the volume of the liquid it contains isn"t directly proportional to the liquid"s depth-space the resistors accordingly or use a nonlinear progression of resistor values and retain constant resistor spacing.