LOW COST LASER DIODE DRIVER

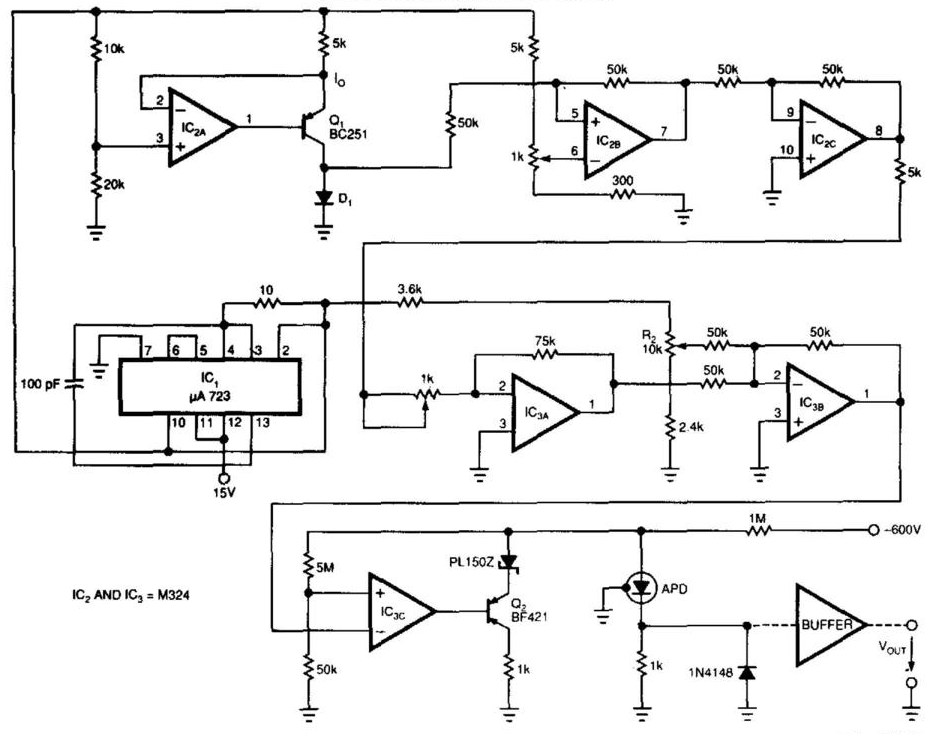

The presented circuit is a cost-effective laser diode driver that includes current limiting and a lasing monitor to ensure the safe operation of the laser. It incorporates a temperature stabilization feature utilizing a built-in thermoelectric cooler (TEC) controller. This design is centered around the QLM5S876 1.55-m laser diode module, which has an integrated monitor photodiode, TEC, and thermistor. The laser is powered by a constant-current source formed by transistors Q2 and Q1. The drive current is stabilized against variations in supply voltage by Z1, limited by resistor R2, and fine-tuned to the desired operating point using resistor R3. When the current is low, the laser does not emit light, and the monitor photodiode detects no optical output, causing comparator U1C to fall below its threshold, resulting in LED1 being turned off. As the current is increased and surpasses the laser's threshold, sufficient optical power is generated, allowing current to flow through the photodiode, which activates the comparator to turn LED1 on, indicating lasing. The TEC controller functions as a feedback system; if the temperature exceeds the set point, the comparator output becomes high, activating the TEC element through resistors R15 and transistors Q3 and Q4. The TEC drive current is restricted by Z2. When the TEC is engaged, it cools the laser, which raises the voltage at the inverting output until it exceeds the comparator's upper threshold, deactivating the TEC's drive current. The temperature set point can be adjusted using resistor R16.

The laser diode driver circuit is particularly designed for applications requiring precise temperature control and stable current supply to the laser diode. The core components include the laser diode module, which features an integrated monitor photodiode that provides feedback on the optical output, allowing for real-time monitoring of the laser's operational status. The use of a thermoelectric cooler (TEC) is crucial for maintaining optimal operating temperatures, especially in environments where thermal fluctuations could lead to performance degradation or damage to the laser.

The constant-current source configuration ensures that the laser diode receives a steady current, thereby preventing fluctuations that could lead to instability in the laser output. The current limiting feature, implemented through resistor R2, protects the laser diode from overcurrent conditions, which could otherwise lead to failure. The adjustment of the operating point via resistor R3 allows for fine-tuning of the laser output, ensuring that it meets the specific requirements of the application.

The feedback mechanism involving the TEC is vital for effective thermal management. The comparator circuit continuously monitors the temperature of the laser diode and adjusts the TEC operation accordingly. When the temperature exceeds the predefined set point, the TEC is activated to cool the laser, thereby stabilizing its performance. The ability to adjust the temperature set point via resistor R16 provides flexibility for various operational conditions, making this circuit suitable for a wide range of applications in laser technology. Overall, this laser diode driver circuit exemplifies an efficient design approach that combines safety, stability, and adaptability for high-performance laser applications.The circuit presented is a low-cost laser-diode driver with current limiting and a lasing monitor for safe operation of the laser. The driver provides temperature stabilization using a built-in thermoelectric-cooler (TEC) controller.

This circuit is designed around a QLM5S876 1. 55-m laser-diode module with a built-in monitor photodiode, TEC, and t hermistor. The laser is driven by the constant-current source Q2 and Q1. The drive current is stabilized against supply changes by Z1, limited by R2, and adjusted by R3 to the desired operating point. When the current is small, the laser doesn`t lase and the monitor photodiode detects no optical power.

As a result, comparator U1C goes below its trip point and LED1 turns off. When the current is adjusted and passes the laser threshold, sufficient optical power is generated by the laser, causing photo current to flow through the photodiode and the comparator to drive the lasing monitor indicator LED1 to on. The TEC controller circuit is a feedback system. If the temperature is higher than the set point, the comparator output will be high and will drive the TEC element through R15, Q3, and Q4.

The TEC drive current is limited by Z2. When the TEC is driven on, it cools the laser. This increases the voltage of the inverting output until it passes the comparator`s upper trip point and turns off the TEC`s drive current. The temperature set point can be adjusted by R16. 🔗 External reference

The laser diode driver circuit is particularly designed for applications requiring precise temperature control and stable current supply to the laser diode. The core components include the laser diode module, which features an integrated monitor photodiode that provides feedback on the optical output, allowing for real-time monitoring of the laser's operational status. The use of a thermoelectric cooler (TEC) is crucial for maintaining optimal operating temperatures, especially in environments where thermal fluctuations could lead to performance degradation or damage to the laser.

The constant-current source configuration ensures that the laser diode receives a steady current, thereby preventing fluctuations that could lead to instability in the laser output. The current limiting feature, implemented through resistor R2, protects the laser diode from overcurrent conditions, which could otherwise lead to failure. The adjustment of the operating point via resistor R3 allows for fine-tuning of the laser output, ensuring that it meets the specific requirements of the application.

The feedback mechanism involving the TEC is vital for effective thermal management. The comparator circuit continuously monitors the temperature of the laser diode and adjusts the TEC operation accordingly. When the temperature exceeds the predefined set point, the TEC is activated to cool the laser, thereby stabilizing its performance. The ability to adjust the temperature set point via resistor R16 provides flexibility for various operational conditions, making this circuit suitable for a wide range of applications in laser technology. Overall, this laser diode driver circuit exemplifies an efficient design approach that combines safety, stability, and adaptability for high-performance laser applications.The circuit presented is a low-cost laser-diode driver with current limiting and a lasing monitor for safe operation of the laser. The driver provides temperature stabilization using a built-in thermoelectric-cooler (TEC) controller.

This circuit is designed around a QLM5S876 1. 55-m laser-diode module with a built-in monitor photodiode, TEC, and t hermistor. The laser is driven by the constant-current source Q2 and Q1. The drive current is stabilized against supply changes by Z1, limited by R2, and adjusted by R3 to the desired operating point. When the current is small, the laser doesn`t lase and the monitor photodiode detects no optical power.

As a result, comparator U1C goes below its trip point and LED1 turns off. When the current is adjusted and passes the laser threshold, sufficient optical power is generated by the laser, causing photo current to flow through the photodiode and the comparator to drive the lasing monitor indicator LED1 to on. The TEC controller circuit is a feedback system. If the temperature is higher than the set point, the comparator output will be high and will drive the TEC element through R15, Q3, and Q4.

The TEC drive current is limited by Z2. When the TEC is driven on, it cools the laser. This increases the voltage of the inverting output until it passes the comparator`s upper trip point and turns off the TEC`s drive current. The temperature set point can be adjusted by R16. 🔗 External reference