Low-power-magnetic-current-sensor

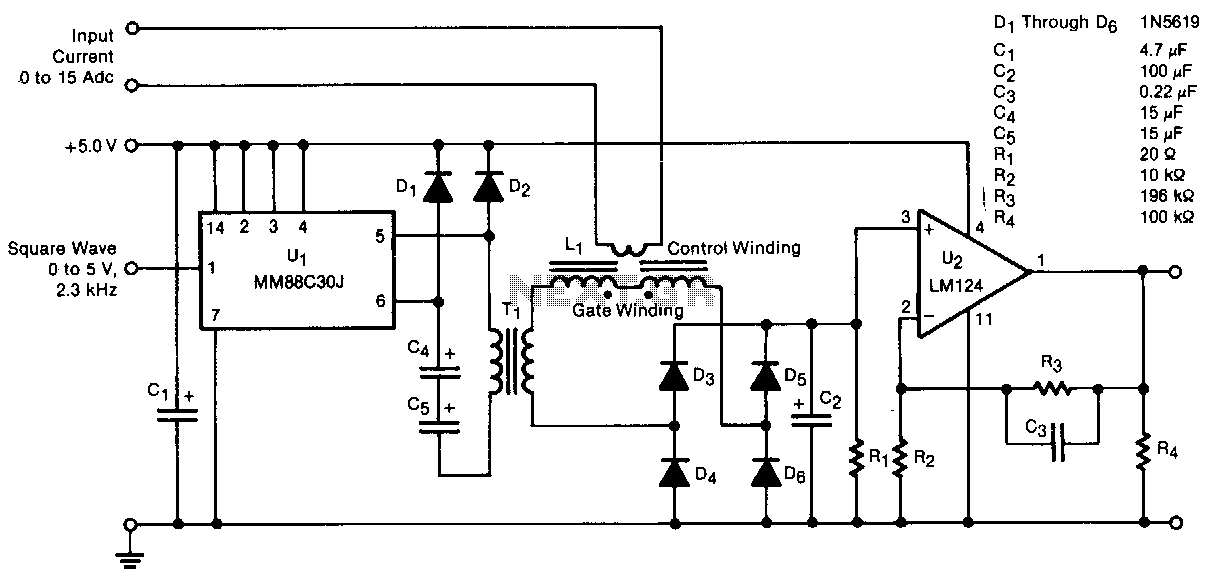

A transducer senses direct current magnetically, providing isolation between the input and the output. The detecting and isolating element is a saturable reactor, through which the input current to be measured passes via a one-turn control coil. The transducer offers an output of 0 to 3 Vdc, an input current range of 0 to 15 Adc, and consumes 22 mW at a 10 Adc input. Line driver U1 excites the saturable reactor L1 by supplying a 2.3-kHz square wave through transformer T1. The output of L1 is rectified by a bridge rectifier composed of diodes D3 through D6 and is subsequently amplified by operational amplifier U2, which has a gain of 20. Diodes D1 and D2 commutate the reactive current fed back to the primary of T1 from L1. Without these diodes, large reactive voltage spikes on the primary could waste power and potentially damage U1. Filter capacitor C1 stores the energy fed back through D1 and D2. To minimize core losses, the core of T1 is constructed from an alloy of 80% nickel and 20% iron. To reduce capacitance, the primary and secondary windings are interleaved and progressively wound at 350 degrees. The primary and secondary windings consist of 408 and 660 turns, respectively, made from #34 wire.

The described transducer circuit utilizes a saturable reactor as the key sensing and isolating component, allowing for the accurate measurement of direct current while maintaining electrical isolation between the input and output. The input current is sensed through a single-turn control coil, which influences the operation of the saturable reactor, leading to a controlled output voltage range of 0 to 3 Vdc. The design accommodates a maximum input current of 15 Adc, ensuring versatility for various applications.

The line driver U1 generates a 2.3-kHz square wave signal that energizes the saturable reactor L1 via transformer T1. The transformer plays a crucial role in transferring energy while providing isolation. The output from L1 is then processed through a bridge rectifier formed by diodes D3 to D6, converting the AC signal into a usable DC output. The operational amplifier U2 amplifies this rectified signal, with a gain of 20, ensuring that the output is sufficiently strong for further processing or display.

Diodes D1 and D2 serve an essential function by commutating the reactive current returning to the primary side of transformer T1 from L1. This commutation prevents excessive voltage spikes that could result in power loss or damage to the line driver U1. The inclusion of filter capacitor C1 is critical, as it stores excess energy, smoothing out fluctuations in the current and enhancing overall circuit stability.

The choice of materials and winding techniques in transformer T1 is optimized for performance. The core, made from an alloy of 80% nickel and 20% iron, is selected to minimize core losses, which is vital for maintaining efficiency during operation. Additionally, the interleaved and progressively wound primary and secondary windings help to reduce parasitic capacitance, further improving the efficiency of energy transfer. The winding specifications, with 408 turns for the primary and 660 turns for the secondary using #34 wire, are tailored to achieve the desired inductance and resistance characteristics, ensuring reliable operation across the specified input current range.A transducer senses a direct current magnetically, providing isolation between the input and the output. The detecting-and-isolating element is a saturable reactor, in which the input current, to be measured, passes through a one-tum control coil.

The transducer provides an output of 0 to 3 Vdc, an input current of 0 to 15 Adc, and consumes 22 mW at 10 Adc input. Line driver U1 excites the saturable reactor L1 by feeding a 2 .3-kHz square wave through transformer Tl.

The output of Ll is rectified by the bridge rectifier composed of diodes D3 through D6, then amplified by op amp U2, which has a gain of 20. Diodes D1 and D2 commutate the reactive current fed back to the primary of Tl from Ll. Without these diodes, large reactive voltage spikes on the primary would waste power and could destroy Ul. Filter capacitor C1 stores the energy fed back through Dl and D2. To minimize core losses, the core of T1 is made of an alloy of 80% nickel and 20% iron. To minimize capacitance, the primary and secondary windings are interleaved and progressively wound 350°.

The primary and secondary windings consist of 408 and 660 turns, respectively, of #34 wire.

The described transducer circuit utilizes a saturable reactor as the key sensing and isolating component, allowing for the accurate measurement of direct current while maintaining electrical isolation between the input and output. The input current is sensed through a single-turn control coil, which influences the operation of the saturable reactor, leading to a controlled output voltage range of 0 to 3 Vdc. The design accommodates a maximum input current of 15 Adc, ensuring versatility for various applications.

The line driver U1 generates a 2.3-kHz square wave signal that energizes the saturable reactor L1 via transformer T1. The transformer plays a crucial role in transferring energy while providing isolation. The output from L1 is then processed through a bridge rectifier formed by diodes D3 to D6, converting the AC signal into a usable DC output. The operational amplifier U2 amplifies this rectified signal, with a gain of 20, ensuring that the output is sufficiently strong for further processing or display.

Diodes D1 and D2 serve an essential function by commutating the reactive current returning to the primary side of transformer T1 from L1. This commutation prevents excessive voltage spikes that could result in power loss or damage to the line driver U1. The inclusion of filter capacitor C1 is critical, as it stores excess energy, smoothing out fluctuations in the current and enhancing overall circuit stability.

The choice of materials and winding techniques in transformer T1 is optimized for performance. The core, made from an alloy of 80% nickel and 20% iron, is selected to minimize core losses, which is vital for maintaining efficiency during operation. Additionally, the interleaved and progressively wound primary and secondary windings help to reduce parasitic capacitance, further improving the efficiency of energy transfer. The winding specifications, with 408 turns for the primary and 660 turns for the secondary using #34 wire, are tailored to achieve the desired inductance and resistance characteristics, ensuring reliable operation across the specified input current range.A transducer senses a direct current magnetically, providing isolation between the input and the output. The detecting-and-isolating element is a saturable reactor, in which the input current, to be measured, passes through a one-tum control coil.

The transducer provides an output of 0 to 3 Vdc, an input current of 0 to 15 Adc, and consumes 22 mW at 10 Adc input. Line driver U1 excites the saturable reactor L1 by feeding a 2 .3-kHz square wave through transformer Tl.

The output of Ll is rectified by the bridge rectifier composed of diodes D3 through D6, then amplified by op amp U2, which has a gain of 20. Diodes D1 and D2 commutate the reactive current fed back to the primary of Tl from Ll. Without these diodes, large reactive voltage spikes on the primary would waste power and could destroy Ul. Filter capacitor C1 stores the energy fed back through Dl and D2. To minimize core losses, the core of T1 is made of an alloy of 80% nickel and 20% iron. To minimize capacitance, the primary and secondary windings are interleaved and progressively wound 350°.

The primary and secondary windings consist of 408 and 660 turns, respectively, of #34 wire.