Nixie Clock 2

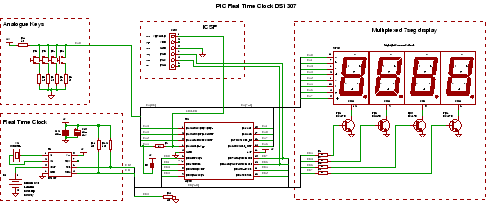

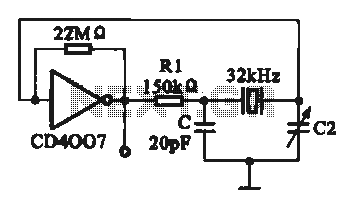

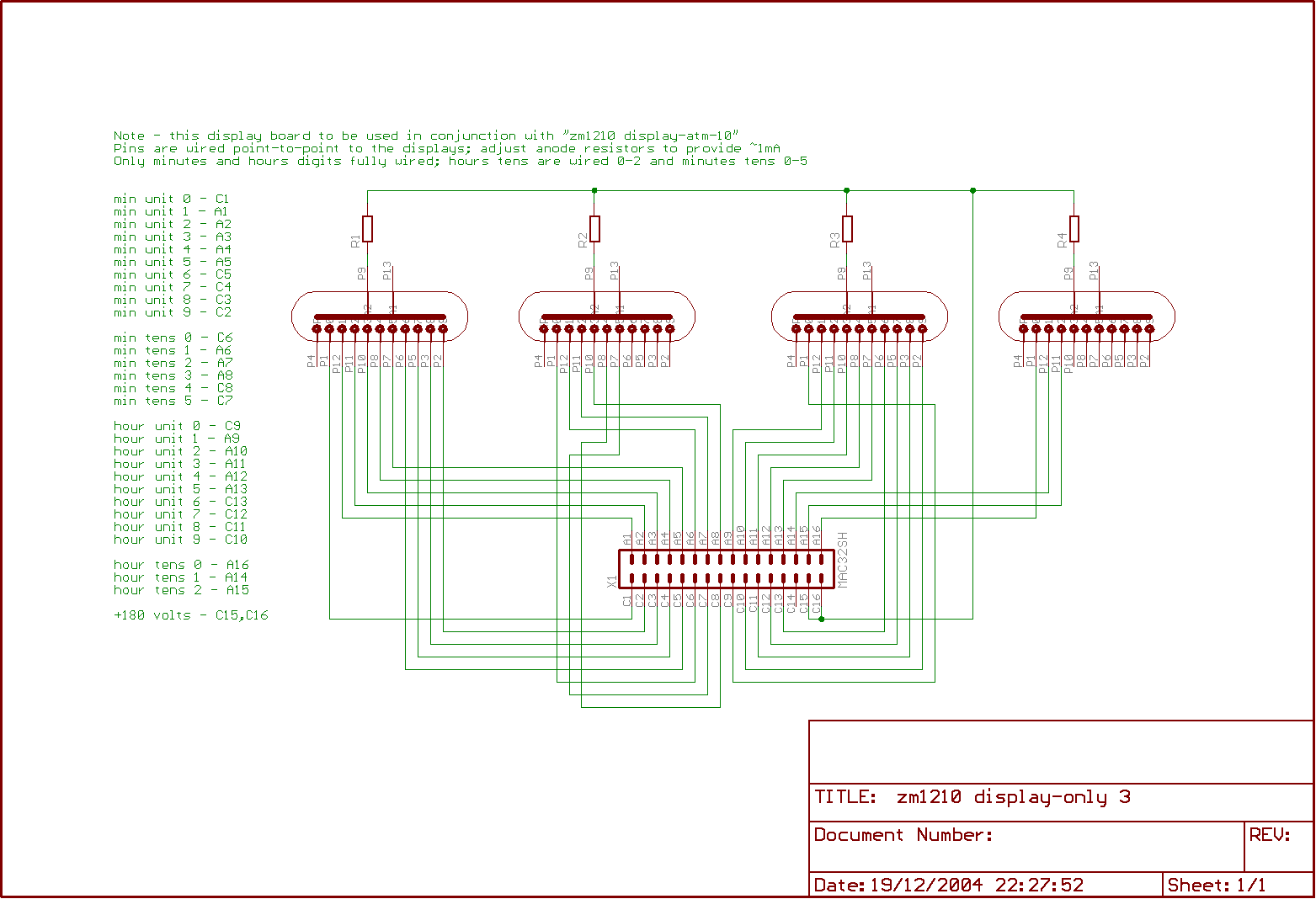

The clock is built on two boards; one contains the high-tension generator and the processor logic, while the other accommodates the tubes. This design offers a more compact layout compared to the previous model, although it does not save as much space as anticipated. The tubes are arranged on a 0.3" DIP grid. While this arrangement is not ideal, it allows for diagonal bracing of the tube legs, providing sufficient separation for tracks to be routed between the lands. A drawback is that if the tubes are positioned closer than half an inch to the board, excessive stress is placed on the leads, which may negatively impact the seal. The enclosure is crafted from recycled ebony; 3mm thick sheets were cut from a block and glued together to form the desired shape. The surface was sanded using a belt sander and finished by hand for smoothness, followed by polishing with Danish oil. Holes were drilled prior to gluing but after cutting, resulting in some slight off-centering due to pre-existing bends in the recycled nixie legs. There were no specific measures taken to regulate the crystal; however, it has been observed to gain about one second per week in operation, which is deemed acceptable. The clock is powered by a surplus laptop power supply providing a regulated 15V at up to 2A, as there was insufficient space for an isolating transformer. An estimate of current draw is around 1mA per tube at 180V, leading to a total of approximately 1.5W for the display, with an additional 200mW for the driver logic. Time setting is facilitated through two switches that share the programming connector. One switch cycles through a normal display, a display showing only hours, and another showing only minutes. The second switch advances the selected time by one hour or minute per click. It is important to note that the circuit board for the display has tracks on the upper side to enable soldering of the connector on a single-sided board. Both boards are single-sided, although the controller board includes several wire links represented as top-side tracks. Caution is advised due to the presence of 180V on the exposed tracks of the upper circuit board and various points on the back of the control board. This voltage is not referenced to ground, posing a risk of electric shock. Individuals without expertise in handling high voltages should refrain from building or operating this circuit.

The clock circuit operates on a dual-board system, enhancing both functionality and compactness. The high-tension generator and the processor logic are strategically placed on one board, while the tubes are situated on a separate board. This layout not only aids in space management but also allows for better thermal dissipation and easier troubleshooting. The use of a 0.3" DIP grid for tube placement, although not optimal, ensures that the tube legs are adequately supported through diagonal bracing. This design consideration mitigates the risk of mechanical stress on the tube leads, which is crucial for maintaining the integrity of the seals and overall performance of the nixie tubes.

The enclosure, crafted from recycled ebony, adds an aesthetic value while also being environmentally conscious. The process of cutting, gluing, sanding, and polishing the ebony sheets showcases a commitment to quality craftsmanship. The decision to drill holes prior to assembly demonstrates foresight in design, although the slight misalignment due to pre-bent legs of the nixie tubes highlights the challenges of using recycled components.

In terms of power supply, the choice of a surplus laptop power supply is both practical and efficient, providing a regulated 15V output capable of handling the necessary current for the nixie tubes and the driver logic. The estimated current consumption of 1mA per tube at 180V indicates a well-calibrated design that balances performance with energy efficiency. The time-setting mechanism, utilizing two switches for user interaction, is intuitive and enhances the overall user experience.

Safety precautions are paramount, given the presence of high voltage on the circuit boards. The warning regarding the potential for electric shock is critical, emphasizing the importance of proper handling and the need for adequate safety measures when working with high-voltage electronics. This detailed design not only serves as a timekeeping device but also as a testament to innovative engineering and the importance of safety in electronics.The clock is constructed on two boards; one carries the HT generator and the processor logic, the other the tubes. Thisallows a slightly more compact design that the previous effort, but didn`t save as much real estate as I`d hoped.

The tubes are mounted on a DIP 0. 3" grid. This isn`t ideal, but it has the advantage that the tube legs are diagonally braced and are far enough separated that tracks can be run between the lands. The bad news is that if the tubes are placed nearer than half an inch or so to the board, there is excessive stress on the leads which might have adverse effects on the seal. The box is cut from recycled ebony. 3mm thick sheets were cut from a block and glued together to create the shape; it was sanded on a belt and then by hand for the smooth surface, which was then polished using Danish oil and elbow grease.

The holes were drilled before glueing but after cutting. The reason they`re a little off-centre isn`t a problem with the circuit board; I used recycled nixies too and the legs were a little bent before I soldered them in, and the holes are cut to fit. There are no particular efforts taken to regulate the crystal, but in service in the case, it`s been gaining a second a week.

Near enough for me, I think; it`s usually closer to the real time than another mains-regulated nixie clock I also have. I don`t like mains on circuit boards, particularly when - as here - there might be a risk of exposed mains in the case of a breakage, and there wasn`t room for an isolating transformer, so instead the clock is powered through a surplus laptop power supply, providing a regulated 15v at up to 2A.

I haven`t measured the current, but as an estimate - 1mA each at 180v for the tubes; say 50% conversion efficiency gives about 1. 5W for the display, and maybe 200mW for the driver logic. The time is set using the two switches which share the programming connector. One switch cycles between a normal display, a display where only the hours are visible, and one when only the minutes are visible.

The other advances the selected time one hour or minute forward per click. You`ll see that the circuit board for the display has the tracks uppermost. It`s impossible to solder the connector on a single sided board otherwise. Both boards are single sided, though the controller board has half a dozen wire links which I`ve shown on the layouts as top-side tracks. Be warned; there are 180v on the exposed tracks on the upper circuit board, and also at sundry points along the back of the control board.

It`s not referenced to earth, but there`s still enough volts there to give you a jolt and enough current for a potentially dangerous or fatal shock. If you don`t know what you`re doing around high voltages, don`t build or operate this circuit. 🔗 External reference

The clock circuit operates on a dual-board system, enhancing both functionality and compactness. The high-tension generator and the processor logic are strategically placed on one board, while the tubes are situated on a separate board. This layout not only aids in space management but also allows for better thermal dissipation and easier troubleshooting. The use of a 0.3" DIP grid for tube placement, although not optimal, ensures that the tube legs are adequately supported through diagonal bracing. This design consideration mitigates the risk of mechanical stress on the tube leads, which is crucial for maintaining the integrity of the seals and overall performance of the nixie tubes.

The enclosure, crafted from recycled ebony, adds an aesthetic value while also being environmentally conscious. The process of cutting, gluing, sanding, and polishing the ebony sheets showcases a commitment to quality craftsmanship. The decision to drill holes prior to assembly demonstrates foresight in design, although the slight misalignment due to pre-bent legs of the nixie tubes highlights the challenges of using recycled components.

In terms of power supply, the choice of a surplus laptop power supply is both practical and efficient, providing a regulated 15V output capable of handling the necessary current for the nixie tubes and the driver logic. The estimated current consumption of 1mA per tube at 180V indicates a well-calibrated design that balances performance with energy efficiency. The time-setting mechanism, utilizing two switches for user interaction, is intuitive and enhances the overall user experience.

Safety precautions are paramount, given the presence of high voltage on the circuit boards. The warning regarding the potential for electric shock is critical, emphasizing the importance of proper handling and the need for adequate safety measures when working with high-voltage electronics. This detailed design not only serves as a timekeeping device but also as a testament to innovative engineering and the importance of safety in electronics.The clock is constructed on two boards; one carries the HT generator and the processor logic, the other the tubes. Thisallows a slightly more compact design that the previous effort, but didn`t save as much real estate as I`d hoped.

The tubes are mounted on a DIP 0. 3" grid. This isn`t ideal, but it has the advantage that the tube legs are diagonally braced and are far enough separated that tracks can be run between the lands. The bad news is that if the tubes are placed nearer than half an inch or so to the board, there is excessive stress on the leads which might have adverse effects on the seal. The box is cut from recycled ebony. 3mm thick sheets were cut from a block and glued together to create the shape; it was sanded on a belt and then by hand for the smooth surface, which was then polished using Danish oil and elbow grease.

The holes were drilled before glueing but after cutting. The reason they`re a little off-centre isn`t a problem with the circuit board; I used recycled nixies too and the legs were a little bent before I soldered them in, and the holes are cut to fit. There are no particular efforts taken to regulate the crystal, but in service in the case, it`s been gaining a second a week.

Near enough for me, I think; it`s usually closer to the real time than another mains-regulated nixie clock I also have. I don`t like mains on circuit boards, particularly when - as here - there might be a risk of exposed mains in the case of a breakage, and there wasn`t room for an isolating transformer, so instead the clock is powered through a surplus laptop power supply, providing a regulated 15v at up to 2A.

I haven`t measured the current, but as an estimate - 1mA each at 180v for the tubes; say 50% conversion efficiency gives about 1. 5W for the display, and maybe 200mW for the driver logic. The time is set using the two switches which share the programming connector. One switch cycles between a normal display, a display where only the hours are visible, and one when only the minutes are visible.

The other advances the selected time one hour or minute forward per click. You`ll see that the circuit board for the display has the tracks uppermost. It`s impossible to solder the connector on a single sided board otherwise. Both boards are single sided, though the controller board has half a dozen wire links which I`ve shown on the layouts as top-side tracks. Be warned; there are 180v on the exposed tracks on the upper circuit board, and also at sundry points along the back of the control board.

It`s not referenced to earth, but there`s still enough volts there to give you a jolt and enough current for a potentially dangerous or fatal shock. If you don`t know what you`re doing around high voltages, don`t build or operate this circuit. 🔗 External reference