Prevent tampering in energy meters

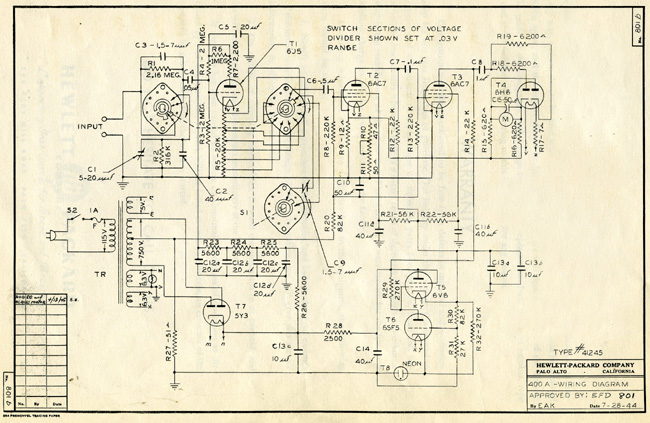

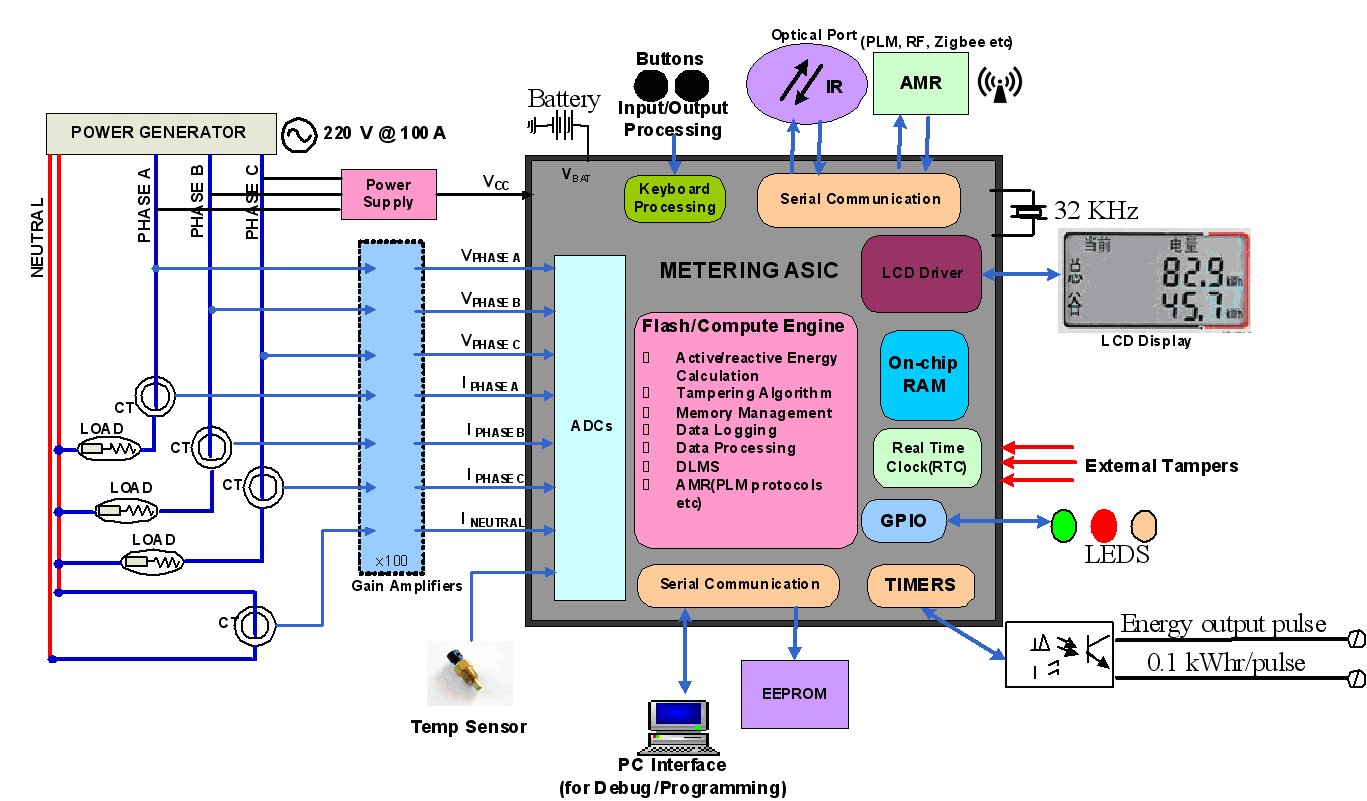

Consumers have been found manipulating their electric meters, causing them to stop, under-register, or even bypass the meter, effectively using power without paying for it. An energy meter is a device that measures the amount of electrical energy supplied to a consumer. The unit of measurement for an energy meter is the kilowatt-hour, which is equal to the energy consumed by a load of one kilowatt in one hour. A system block diagram for a three-phase energy meter includes several hardware components: a power supply, an analog front end, a microcontroller section, and an interface section. The analog front end interfaces with high voltage lines, converting high voltages and currents into lower voltages that can be measured directly by the ADC (Analog/Digital Converter) of the microcontroller. Voltage measurement is performed using a shunt resistor, while current measurements, which require higher precision, are conducted via Current Transformers (CT) on all phases, as well as on the neutral line. Meter manufacturers often incorporate gain amplifiers to enhance voltage and current measurements within the ADC's supported range. The required amplification level depends on the ADC's resolution and the Class accuracy (e.g., 0.1, 0.2, 1.0) specified for a three-phase meter. Additionally, a typical energy meter incorporates a Real-Time Clock (RTC) for managing tariff information. The RTC must maintain high accuracy (< 5ppm) for Time of Day (TOD) applications, which segment the day, month, and year into tariff slots. Higher rates are applied during peak load periods, while lower rates are assigned during off-peak periods. The meter's firmware is crucial, as it calculates active and reactive energy based on voltage and current measurements. The firmware also includes tamper detection algorithms, data logging capabilities, and communication protocols such as DLMS and Power Line Modem for Automatic Meter Reading (AMR). Before use, the energy meter must undergo calibration, which is performed digitally in electronic meters. Digital calibration is efficient and can be automated, eliminating the time-consuming manual adjustments needed in traditional electromechanical meters. Calibration coefficients are securely stored in an EEPROM, which can be either internal or external. An energy pulse output (EP) indicates active power as recorded by the meter, with the pulse frequency being directly proportional to the active power consumption.

The three-phase energy meter operates by accurately measuring and recording the electrical energy consumption across three separate phases. Each phase is monitored through dedicated current transformers, which ensure precise current measurements. The analog front end is vital for transforming the high voltage inputs into a format suitable for the microcontroller's ADC. This transformation is essential for maintaining the integrity of the measurements and ensuring compliance with required accuracy standards.

The microcontroller processes the measurements, executing firmware algorithms that compute both active and reactive energy consumption. The integration of tamper detection algorithms enhances security, preventing unauthorized manipulation of the meter readings. The communication protocols implemented, such as DLMS, allow for seamless data exchange between the meter and remote monitoring systems, facilitating efficient energy management and billing processes.

Calibration of the energy meter is a critical step in ensuring its accuracy and reliability. The digital calibration process is designed to be swift and efficient, allowing for the automatic adjustment of measurement parameters based on pre-defined standards. The use of EEPROM for storing calibration coefficients ensures that the data is retained even in the event of power loss, thereby maintaining the meter's operational integrity.

Overall, the design and functionality of a three-phase energy meter are centered around accurate measurement, secure data handling, and efficient communication, which collectively contribute to effective energy management and billing practices.Consumers have been found manipulating their electric meters, causing them to stop, under-register or even bypassing the meter, effectively using power without paying for it. An energy meter is a device that measures the amount of electrical energy supplied to a a meter is the kilowatt hour, which is equal to the amount of energy used by a load of one kilowatt in one hour. Figure 1 shows a system block diagram for a three-phase energy meter. As shown the energy meter hardware includes a power supply, an analog front end, a microcontroller section, and an interface section.

The analog front end is the part that interfaces to the high voltage lines. It converts high voltages and high currents to voltages sufficiently small to be measured directly by the ADC (Analog/Digital Converter) of the microcontroller. Voltage measurement is done with a shunt resister (shown as "Load"), while the current measurements require more precise measurement and thus are done by Current Transformer (CT) on all phases along with current measurement on neutral.

Meter manufacturers often integrate gain amplifiers in order to amplify voltage as well as current measurements in the range supported by the ADC. The amount of amplification required depends on the ADC resolution as well as the Class accuracy (0. 1, 0. 2. 1. 0 etc. ) required for a three-phase meter. A typical energy meter also requires a Real Time Clock (RTC) for tariff information. The RTC required for a metering application needs to be very accurate (< 5ppm) for Time of Day (TOD), which involves dividing the day, month and year into tariff slots.

Higher rates are applied at peak load periods and lower tariff rates at off-peak load periods. The heart of the meter is the firmware, which calculates Active, reactive energy based on voltage and current measurement. The firmware also includes tamper detection algorithms, data logging and protocols like DLMS and Power Line Modem communication protocol for Automatic Meter Reading (AMR).

The energy meter also needs to be calibrated before it can be used and that is done in a digital domain for an electronic meter. Digital calibration is fast, efficient and can be automated, removing the time-consuming manual trimming required in traditional, electromechanical meters.

Calibration coefficients are safely stored in an EEPROM that can be either internal or external. An energy pulse output (EP) is an indication of active power, as registered by the meter; the frequency of the pulse is directly proportional to active power. 🔗 External reference

The three-phase energy meter operates by accurately measuring and recording the electrical energy consumption across three separate phases. Each phase is monitored through dedicated current transformers, which ensure precise current measurements. The analog front end is vital for transforming the high voltage inputs into a format suitable for the microcontroller's ADC. This transformation is essential for maintaining the integrity of the measurements and ensuring compliance with required accuracy standards.

The microcontroller processes the measurements, executing firmware algorithms that compute both active and reactive energy consumption. The integration of tamper detection algorithms enhances security, preventing unauthorized manipulation of the meter readings. The communication protocols implemented, such as DLMS, allow for seamless data exchange between the meter and remote monitoring systems, facilitating efficient energy management and billing processes.

Calibration of the energy meter is a critical step in ensuring its accuracy and reliability. The digital calibration process is designed to be swift and efficient, allowing for the automatic adjustment of measurement parameters based on pre-defined standards. The use of EEPROM for storing calibration coefficients ensures that the data is retained even in the event of power loss, thereby maintaining the meter's operational integrity.

Overall, the design and functionality of a three-phase energy meter are centered around accurate measurement, secure data handling, and efficient communication, which collectively contribute to effective energy management and billing practices.Consumers have been found manipulating their electric meters, causing them to stop, under-register or even bypassing the meter, effectively using power without paying for it. An energy meter is a device that measures the amount of electrical energy supplied to a a meter is the kilowatt hour, which is equal to the amount of energy used by a load of one kilowatt in one hour. Figure 1 shows a system block diagram for a three-phase energy meter. As shown the energy meter hardware includes a power supply, an analog front end, a microcontroller section, and an interface section.

The analog front end is the part that interfaces to the high voltage lines. It converts high voltages and high currents to voltages sufficiently small to be measured directly by the ADC (Analog/Digital Converter) of the microcontroller. Voltage measurement is done with a shunt resister (shown as "Load"), while the current measurements require more precise measurement and thus are done by Current Transformer (CT) on all phases along with current measurement on neutral.

Meter manufacturers often integrate gain amplifiers in order to amplify voltage as well as current measurements in the range supported by the ADC. The amount of amplification required depends on the ADC resolution as well as the Class accuracy (0. 1, 0. 2. 1. 0 etc. ) required for a three-phase meter. A typical energy meter also requires a Real Time Clock (RTC) for tariff information. The RTC required for a metering application needs to be very accurate (< 5ppm) for Time of Day (TOD), which involves dividing the day, month and year into tariff slots.

Higher rates are applied at peak load periods and lower tariff rates at off-peak load periods. The heart of the meter is the firmware, which calculates Active, reactive energy based on voltage and current measurement. The firmware also includes tamper detection algorithms, data logging and protocols like DLMS and Power Line Modem communication protocol for Automatic Meter Reading (AMR).

The energy meter also needs to be calibrated before it can be used and that is done in a digital domain for an electronic meter. Digital calibration is fast, efficient and can be automated, removing the time-consuming manual trimming required in traditional, electromechanical meters.

Calibration coefficients are safely stored in an EEPROM that can be either internal or external. An energy pulse output (EP) is an indication of active power, as registered by the meter; the frequency of the pulse is directly proportional to active power. 🔗 External reference