Responsive Wearable Technology

Various circuit combinations were initially tested using alligator clips and different code interactions. The circuits were designed to turn on either individually and sequentially (A, B, C) or to turn on sequentially while remaining lit (A, AB, ABC). Blinking lights were also experimented with, but they did not align with the concept of scale. The circuit was planned to avoid overlaps, and electrical tape was employed to conceal the circuits, providing a quick solution to prevent short-circuiting. Attaching the Force Sensing Resistor (FSR) posed a challenge, as a needle could not penetrate it; fabric glue was ultimately used, which proved effective. The conductive thread attachment was also difficult due to the proximity of the connections. The FSR's form factor was not ideal for the intended application, as it required the contents of the bag to be positioned directly on the sensor for accurate measurement. An ideal configuration would have the sensor extending along the entire bottom of the bag for even weight distribution. Although placing the sensor on the shoulder strap was initially considered, the choice was made to position the FSR at the bottom of the bag. In retrospect, the shoulder strap may have provided more stable pressure readings, as random objects inside the bag could disrupt measurements. Additionally, applying pressure to the bottom of the bag with fingers demonstrated potential for a new concept: a discrete signal indicating to a friend when to leave a party, with the meter reflecting the urgency of departure.

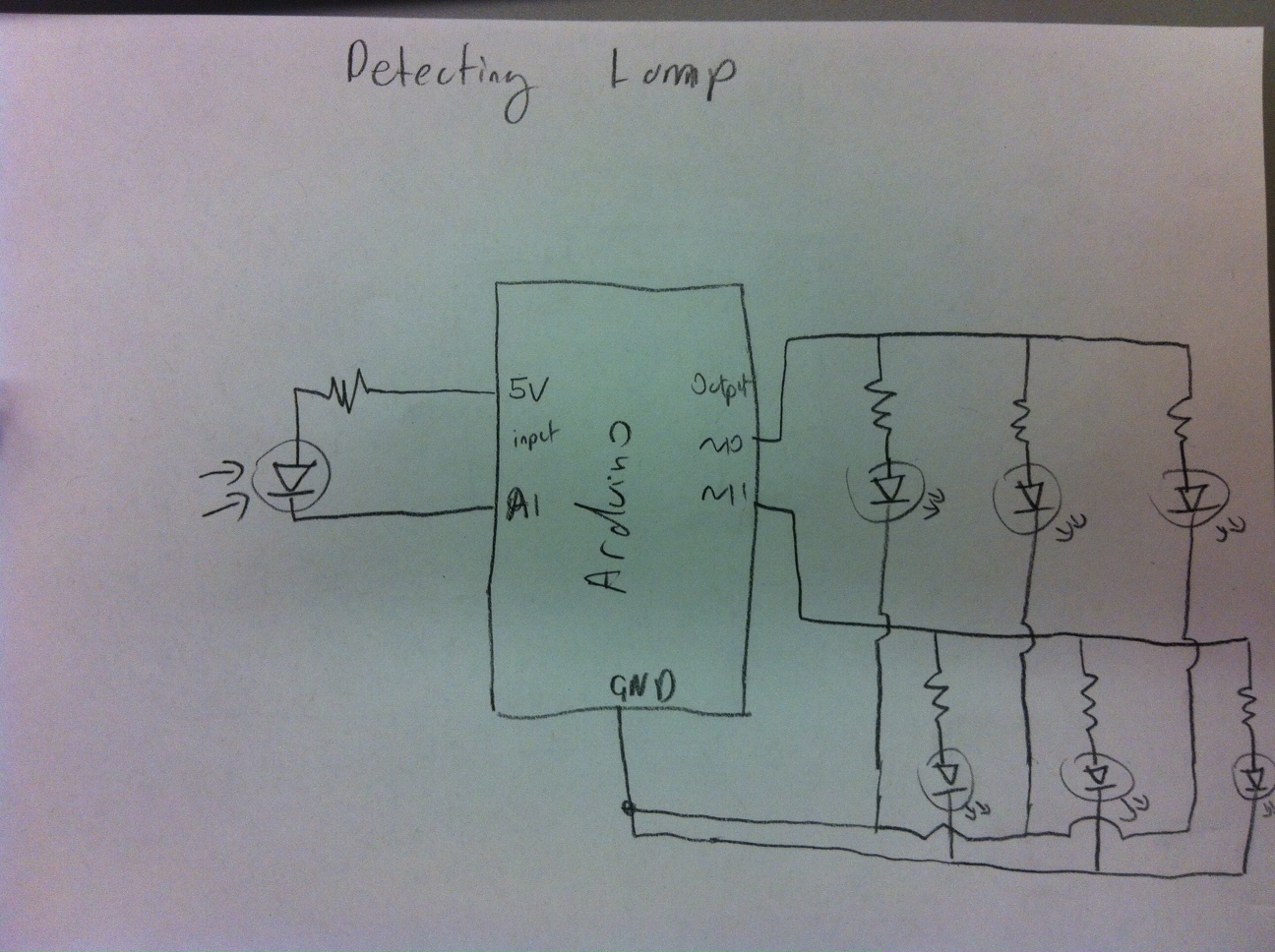

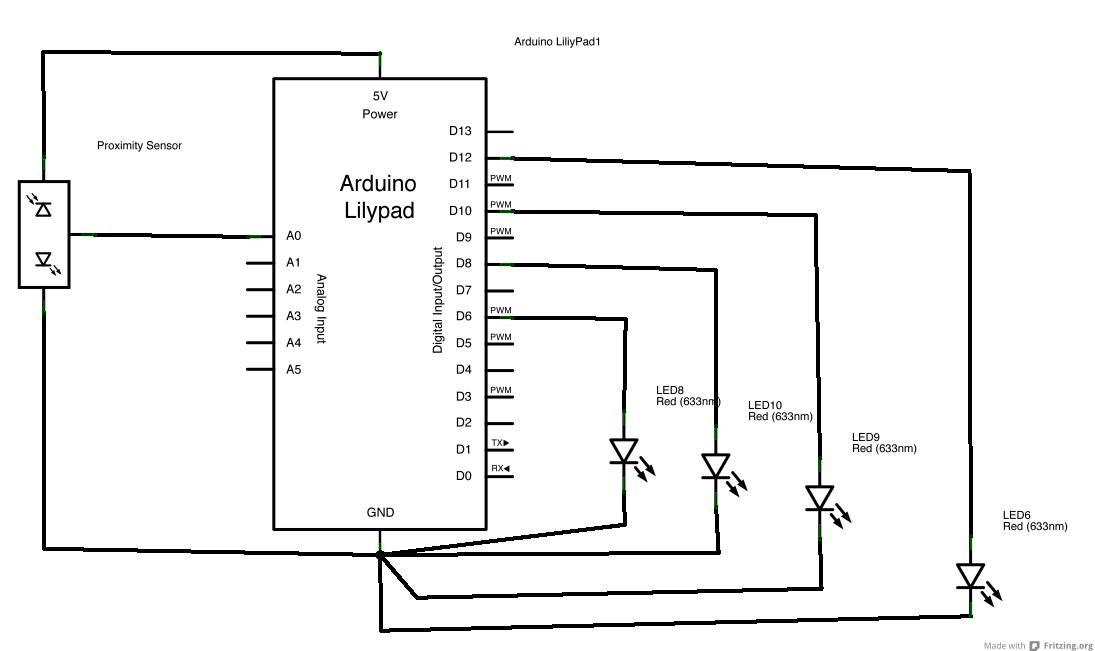

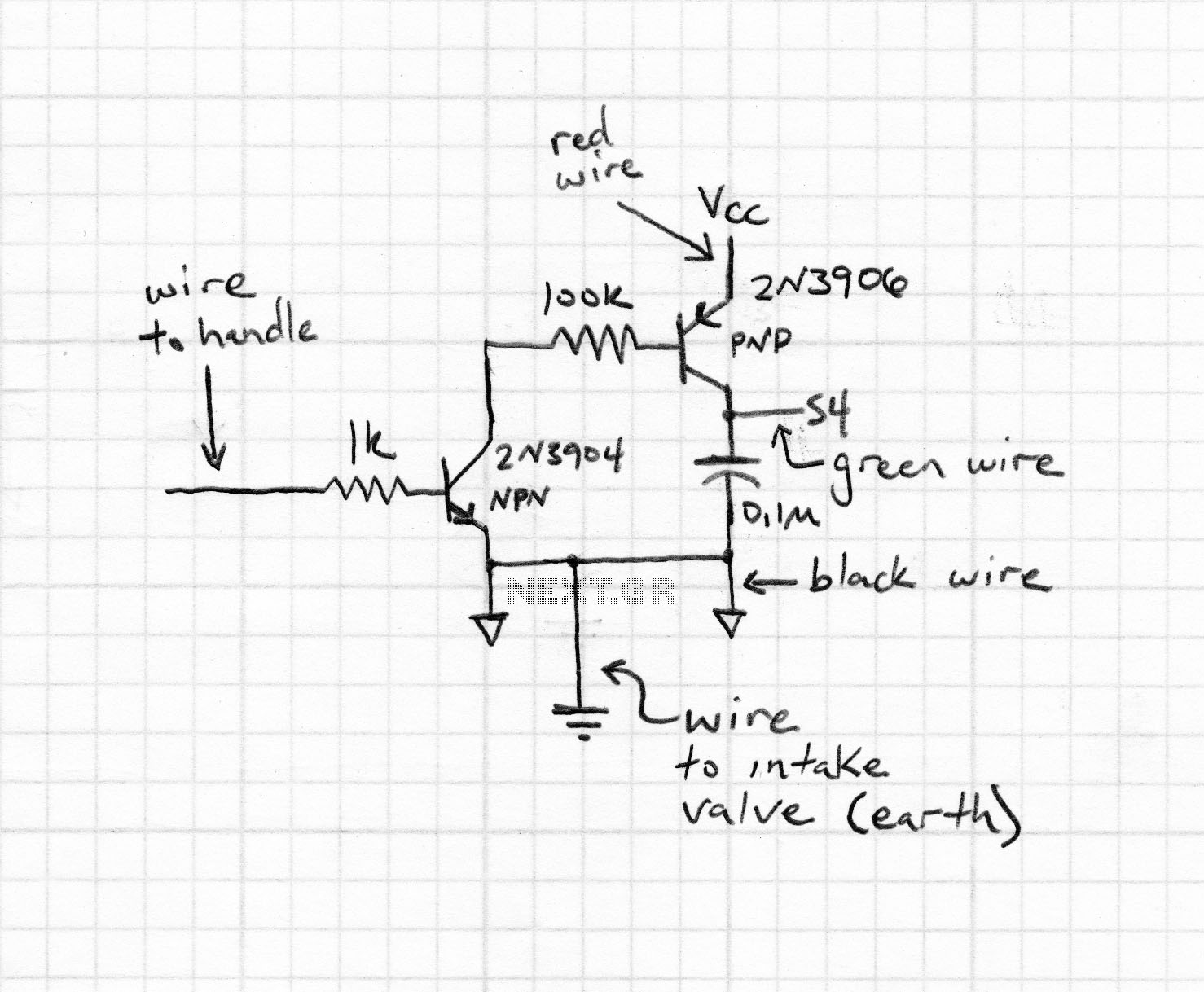

The circuit design integrates an FSR to measure pressure applied to the bottom of a bag, which can be influenced by the weight of the contents or direct pressure from fingers. The FSR operates by changing its resistance based on the force applied, enabling the system to detect varying levels of pressure. The circuit configuration includes a microcontroller to process the analog signal from the FSR, converting it into a digital signal that can be read and interpreted.

To enhance the functionality, a series of LEDs can be incorporated, programmed to light up in different sequences based on the pressure readings. For instance, the microcontroller could be programmed to activate LEDs sequentially as pressure increases, indicating different weight thresholds. This could be useful for visual feedback regarding the urgency of leaving a location, with a specific LED pattern signifying different levels of urgency.

The use of electrical tape to secure connections and prevent short-circuiting is a practical approach, ensuring the reliability of the circuit. Careful planning of the circuit layout is crucial to avoid overlaps, which could lead to unintended connections and malfunction. The decision to use fabric glue for attaching the FSR highlights the importance of selecting appropriate materials for securing components in a way that maintains functionality without compromising the integrity of the circuit.

In summary, the project demonstrates a creative application of sensor technology, exploring the interaction between physical pressure and electronic feedback. The potential for further development exists, particularly in refining the placement of the FSR for optimal performance and exploring additional functionalities that could enhance user experience.I first tried a lot of different circuit combinations with alligator clips and different interactions with code. For example, I could have them turn on individually and sequentially (A, B, C) or have them turn on sequentially but stay lit (A, AB, ABC).

I tried blinking lights as well, but it didn`t seem appropriate for the scale` concept. I planne d my circuit out so that there would be no over laps. But just to be absolutely certain, I used electrical tape to hide the circuits. It`s not the prettiest, but it`s the fastest way to prevent short circuiting. I actually had no clue how I would attach the FSR. A needle wouldn`t go through it. So I used fabric glue instead, which worked surprisingly well. Attaching conductive thread to it was a bit of a challenge too since they were so close together. The form factor of the FSR is not the best choice for what I wanted to achieve because it requires that the contents in the bag be concentrated right ON the sensor. It would be ideal if the sensor ran along the entire bottom of the bag so that the measurement of the weight is evenly distributed.

Originally, putting the sensor on the shoulder strap was an option, but because the bag I used had a skinny strap, I decided to put the FSR on the bottom of the bag instead. But in hindsight, I think the values would have read much better on the shoulder since the pressure would be more even and stable compared to random objects shuffling inside a bag.

Since applying pressure to the bottom of the bag with fingers also worked, a change of concept could be a discrete signal for a friend to leave a party early where the meter would indicate the urgency of leaving 🔗 External reference

The circuit design integrates an FSR to measure pressure applied to the bottom of a bag, which can be influenced by the weight of the contents or direct pressure from fingers. The FSR operates by changing its resistance based on the force applied, enabling the system to detect varying levels of pressure. The circuit configuration includes a microcontroller to process the analog signal from the FSR, converting it into a digital signal that can be read and interpreted.

To enhance the functionality, a series of LEDs can be incorporated, programmed to light up in different sequences based on the pressure readings. For instance, the microcontroller could be programmed to activate LEDs sequentially as pressure increases, indicating different weight thresholds. This could be useful for visual feedback regarding the urgency of leaving a location, with a specific LED pattern signifying different levels of urgency.

The use of electrical tape to secure connections and prevent short-circuiting is a practical approach, ensuring the reliability of the circuit. Careful planning of the circuit layout is crucial to avoid overlaps, which could lead to unintended connections and malfunction. The decision to use fabric glue for attaching the FSR highlights the importance of selecting appropriate materials for securing components in a way that maintains functionality without compromising the integrity of the circuit.

In summary, the project demonstrates a creative application of sensor technology, exploring the interaction between physical pressure and electronic feedback. The potential for further development exists, particularly in refining the placement of the FSR for optimal performance and exploring additional functionalities that could enhance user experience.I first tried a lot of different circuit combinations with alligator clips and different interactions with code. For example, I could have them turn on individually and sequentially (A, B, C) or have them turn on sequentially but stay lit (A, AB, ABC).

I tried blinking lights as well, but it didn`t seem appropriate for the scale` concept. I planne d my circuit out so that there would be no over laps. But just to be absolutely certain, I used electrical tape to hide the circuits. It`s not the prettiest, but it`s the fastest way to prevent short circuiting. I actually had no clue how I would attach the FSR. A needle wouldn`t go through it. So I used fabric glue instead, which worked surprisingly well. Attaching conductive thread to it was a bit of a challenge too since they were so close together. The form factor of the FSR is not the best choice for what I wanted to achieve because it requires that the contents in the bag be concentrated right ON the sensor. It would be ideal if the sensor ran along the entire bottom of the bag so that the measurement of the weight is evenly distributed.

Originally, putting the sensor on the shoulder strap was an option, but because the bag I used had a skinny strap, I decided to put the FSR on the bottom of the bag instead. But in hindsight, I think the values would have read much better on the shoulder since the pressure would be more even and stable compared to random objects shuffling inside a bag.

Since applying pressure to the bottom of the bag with fingers also worked, a change of concept could be a discrete signal for a friend to leave a party early where the meter would indicate the urgency of leaving 🔗 External reference