Servo Tester Using A 4538

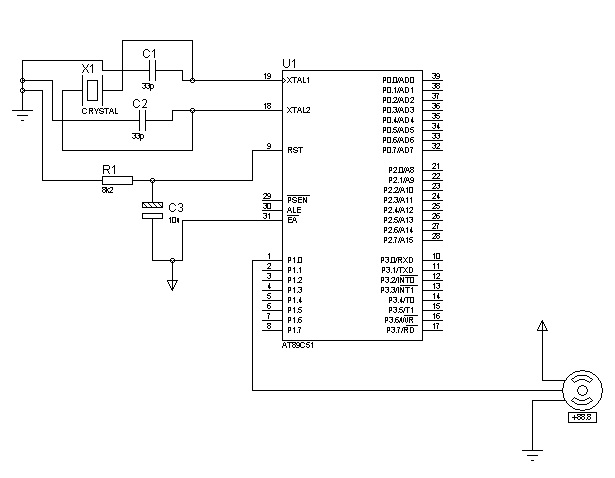

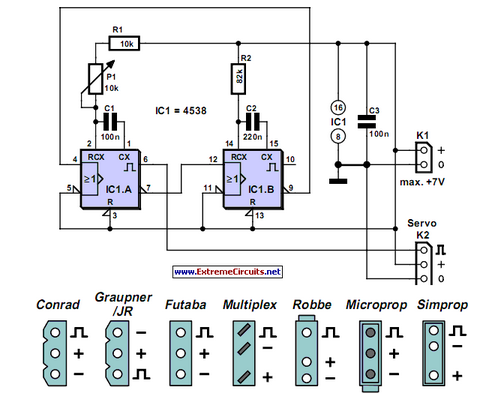

Individuals who frequently work with servos are likely familiar with situations where a servo tester is beneficial. The primary function of a servo tester is to produce a pulsing signal with a variable positive pulse width ranging from 1 to 2 milliseconds. This pulse width dictates the servo's position. The signal must be continuously repeated at a frequency of approximately 40 to 60 Hz. Typically, circuits utilize an NE555 timer or similar components to generate these pulses; however, in this instance, a 4538 integrated circuit (IC) is employed for variety. This IC features two astable multivibrators. The circuit diagram indicates that few additional components are necessary beyond the 4538. The astable multivibrator within the 4538 can be activated in two ways. When input I0 (pin 5 or 11) is high, a rising edge on input I1 (pin 4 or 12) serves as the start signal for pulse generation. The pulse width at the output of IC1a is calculated as (R1 + P1)G—C1. When the potentiometer P1 is adjusted to its minimum resistance, the pulse width is 1 millisecond (10 k G—100 n). Conversely, when P1 is set to its maximum (10 k), the pulse width increases to 2 milliseconds (20 k G—100 n). At the conclusion of this pulse, the inverting output Q generates a rising edge, triggering IC1B to produce a pulse. The pulse width in this case is 18 milliseconds (82 k G—220 n). Following this pulse, the Q output also generates a rising edge, which causes IC1A to produce another pulse, thus completing the cycle. Depending on the setting of P1, the total period ranges from 19 to 20 milliseconds, corresponding to a frequency of approximately 50 to 53 Hz, which is well within the acceptable frequency range.

The servo tester circuit utilizing the 4538 integrated circuit is designed to facilitate precise control of servo motors by generating adjustable pulse-width modulation signals. The 4538 IC, being a dual astable multivibrator, allows for the generation of two distinct pulse signals that can be synchronized for effective servo control. The configuration of resistors R1 and the variable potentiometer P1, along with the timing capacitor C1, determines the output pulse width, which is essential for controlling the angle of the servo.

To ensure stability and reliability in operation, it is advisable to use high-quality components, particularly for the timing capacitor C1, as its value directly influences the pulse timing. The circuit requires a stable power supply, typically within the range of 5 to 15 volts, to ensure consistent performance across different servo types.

The output from the servo tester can be connected directly to the control input of standard servos, which interpret the pulse width as position commands. This feature makes the tester invaluable for both testing and calibrating servos, allowing users to determine the exact pulse width required for specific positions.

In practical applications, the servo tester can be used in various fields, including robotics, automation, and remote-controlled vehicles, where precise servo control is crucial. The ability to adjust the pulse width easily enables users to fine-tune servo responses, ensuring optimal performance in their respective applications.Everybody who regularly works with servos will know several instances when such a servo tester will come in handy. The function of a servo tester is to generate a pulsing signal where the width of the positive pulse can be varied between 1 and 2 ms.

This pulse-width determines the position the servo should move to. The signal has to repeat itself continuously, with a frequency of about 40 to 60 Hz. These circuits often use an NE555 or one of its derivatives to generate the pulses. This time we have used a 4538 for variety. This IC contains two astable multi-vibrators. You can see from the circuit diagram that not many other components are required besides the 4538. The astable multi-vibrator in a 4538 can be started in two ways. When input I 0 (pin 5 or 11) is high, a rising edge on input I 1 (pin 4 or 12) is the start signal to generate a pulse. The pulse-width at the output of IC1a is equal to (R1+P1)G—C1. This means that when potentiometer P1 is turned to its minimum resistance, the pulse-width will be 10 k G— 100 n = 1 ms.

When P1 is set to maximum (10 k), the pulse-width becomes 20 k G— 100 n = 2 ms. At the end of this pulse inverting output Q generates a rising edge. This edge triggers IC1. B, which then generates a pulse. The pulse-width here is 82 k G— 220 n 18 ms. At the end of this pulse the Q output will also generate a rising edge. This in turn makes IC1. A generate a pulse again. This completes the circle. Depending on P1, the total period is between 19 and 20 ms. This corresponds to a frequency of about 50 to 53 Hz and is therefore well within the permitted frequency range. 🔗 External reference

The servo tester circuit utilizing the 4538 integrated circuit is designed to facilitate precise control of servo motors by generating adjustable pulse-width modulation signals. The 4538 IC, being a dual astable multivibrator, allows for the generation of two distinct pulse signals that can be synchronized for effective servo control. The configuration of resistors R1 and the variable potentiometer P1, along with the timing capacitor C1, determines the output pulse width, which is essential for controlling the angle of the servo.

To ensure stability and reliability in operation, it is advisable to use high-quality components, particularly for the timing capacitor C1, as its value directly influences the pulse timing. The circuit requires a stable power supply, typically within the range of 5 to 15 volts, to ensure consistent performance across different servo types.

The output from the servo tester can be connected directly to the control input of standard servos, which interpret the pulse width as position commands. This feature makes the tester invaluable for both testing and calibrating servos, allowing users to determine the exact pulse width required for specific positions.

In practical applications, the servo tester can be used in various fields, including robotics, automation, and remote-controlled vehicles, where precise servo control is crucial. The ability to adjust the pulse width easily enables users to fine-tune servo responses, ensuring optimal performance in their respective applications.Everybody who regularly works with servos will know several instances when such a servo tester will come in handy. The function of a servo tester is to generate a pulsing signal where the width of the positive pulse can be varied between 1 and 2 ms.

This pulse-width determines the position the servo should move to. The signal has to repeat itself continuously, with a frequency of about 40 to 60 Hz. These circuits often use an NE555 or one of its derivatives to generate the pulses. This time we have used a 4538 for variety. This IC contains two astable multi-vibrators. You can see from the circuit diagram that not many other components are required besides the 4538. The astable multi-vibrator in a 4538 can be started in two ways. When input I 0 (pin 5 or 11) is high, a rising edge on input I 1 (pin 4 or 12) is the start signal to generate a pulse. The pulse-width at the output of IC1a is equal to (R1+P1)G—C1. This means that when potentiometer P1 is turned to its minimum resistance, the pulse-width will be 10 k G— 100 n = 1 ms.

When P1 is set to maximum (10 k), the pulse-width becomes 20 k G— 100 n = 2 ms. At the end of this pulse inverting output Q generates a rising edge. This edge triggers IC1. B, which then generates a pulse. The pulse-width here is 82 k G— 220 n 18 ms. At the end of this pulse the Q output will also generate a rising edge. This in turn makes IC1. A generate a pulse again. This completes the circle. Depending on P1, the total period is between 19 and 20 ms. This corresponds to a frequency of about 50 to 53 Hz and is therefore well within the permitted frequency range. 🔗 External reference