SolarPowerChartingTool

The solar cell used for the solar tracking experiment is made from crystalline silicon, with a maximum voltage rating of 55V and a maximum current rating of 300 mA. It can be purchased at local Radio Shack stores for approximately $5. Although the power output is limited, the experiment can be scaled to accommodate higher wattages. Power is defined as the measure of energy per unit time and can be calculated by multiplying voltage by current at the solar cell's output. Since the GP-3 Board can only measure voltage, a current-to-voltage converter circuit will be necessary. This circuit utilizes operational amplifiers to convert the current from the photovoltaic cell into a corresponding voltage (1V corresponds to approximately 10 milliamps).

The first operational amplifier functions as the current-to-voltage converter, taking the current from the solar cell and converting it to a voltage determined by a 100-ohm feedback resistor. However, the output voltage from this op-amp is negative, which cannot be measured by the A/D channel on the GP-3 board. To rectify this, a second op-amp is employed to invert the voltage polarity. The resulting positive voltage is then fed into pin 10 of the GP-3 board, which corresponds to channel #0 of the A/D converter.

The charting program includes a User Control that plots data points on an XY Plotter, a timer control, and an ActiveX control that communicates with the GP-3 board. The program features buttons for starting and stopping the charting process, as well as a calibration checkbox that accelerates data collection for testing purposes. Under normal conditions, data sampling occurs every minute, while in calibration mode, it is increased to every second. The solar charting form illustrates the output resulting from varying the solar cell's position. For practical purposes, data collection is generally conducted every 1 to 5 minutes, as solar intensity does not fluctuate significantly within short intervals. After completing calibration, it is advisable to revert to normal mode by unchecking the calibration box.

In constructing the current-to-voltage converter circuit, it is essential to ensure that the operational amplifiers are configured correctly to maintain accuracy in measurements. The first op-amp should be set up in a non-inverting configuration, where the input current flows through a resistor to produce a voltage drop that is proportional to the current. The feedback resistor value can be adjusted to calibrate the output voltage scale according to the desired current range.

The second op-amp, configured as an inverting amplifier, should have its input connected to the output of the first op-amp, allowing for the inversion of the negative voltage signal. This configuration ensures that the output voltage is suitable for the A/D converter, avoiding any measurement errors due to polarity issues.

The GP-3 board's A/D converter can accurately process the voltage levels generated by the operational amplifiers, enabling effective monitoring of the solar cell's performance. The charting software should be designed to handle incoming data efficiently, providing real-time visualization of the solar power output. This allows for better analysis and understanding of the solar cell's behavior under varying conditions, facilitating further experimentation and optimization of solar tracking systems.

Overall, the combination of the solar cell, current-to-voltage converter circuit, and data visualization software provides a robust platform for exploring solar energy applications and enhancing the efficiency of solar tracking systems.The cell we will use for our solar tracking experiment is made from crystalline silicon and has a maximum voltage rating of. 55V and a maximum current rating of 300 ma. The cell can be picked up in your local Radio Shack for about $5. Although the cell doesn`t produce much power, this experiment can certainly be scaled to handle higher wattages.

Power is the measure of energy per unit time. It can be calculated by multiplying voltage by current at the output of the solar cell. Because our GP-3 Board can only measure voltage, we`ll need to create what is called a current-to-voltage converter circuit. This circuit takes current from the photovoltaic cell and runs it through a couple of operational amplifiers to produce a corresponding voltage (1V corresponds to about 10 milliamps).

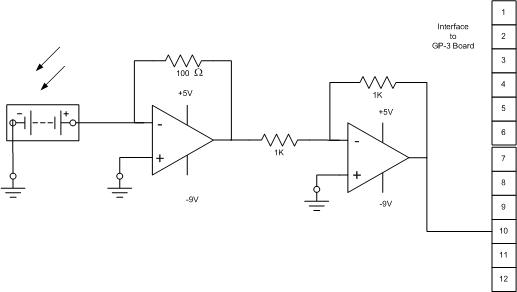

Figure 2 shows the circuit constructed for measuring current from the solar cell. The operational amplifier (also known as a differential amplifier) is a great circuit for sensing or measuring just about anything because it keeps the voltage at one input at a reference point determined by the other input. The first opamp is the current-to-voltage converter. It takes the current from the photovoltaic cell and converts it to a voltage determined by the 100 ohm feedback resistor.

Unfortunately the voltage produced at the output of the first opamp is negative (which the A/D channel on our GP-3 board can`t measure). We need to flip the polarity of this voltage using a second op amp set up to invert the voltage sign.

This positive voltage is then fed into pin 10 of our GP-3 board, which is actually channel #0 of our A/D (Analog to Digital) converter. The charting program consists of a User Control that plots data points on an XY Plotter. (See my previous article, An XY Plotter User Control in GDI+ ), a timer control, and the ActiveX control that talks to the GP-3 board.

The program also has buttons that allow you to start and stop charting and a calibration check box to allow you to speed up data collection to test the program. Normally sampling takes place once every minute. In calibration mode sampling is once every second. Figure 3 shows the solar charting form in calibration mode. The output you see was caused by varying the position of the solar cell: To chart the suns power, it is more practical to take data every 1 minute or every 5 minutes because the sun doesn`t change intensity that drastically every second.

So when you are through in calibration mode, switch back to normal mode by clicking the checkbox again and hit t 🔗 External reference

The first operational amplifier functions as the current-to-voltage converter, taking the current from the solar cell and converting it to a voltage determined by a 100-ohm feedback resistor. However, the output voltage from this op-amp is negative, which cannot be measured by the A/D channel on the GP-3 board. To rectify this, a second op-amp is employed to invert the voltage polarity. The resulting positive voltage is then fed into pin 10 of the GP-3 board, which corresponds to channel #0 of the A/D converter.

The charting program includes a User Control that plots data points on an XY Plotter, a timer control, and an ActiveX control that communicates with the GP-3 board. The program features buttons for starting and stopping the charting process, as well as a calibration checkbox that accelerates data collection for testing purposes. Under normal conditions, data sampling occurs every minute, while in calibration mode, it is increased to every second. The solar charting form illustrates the output resulting from varying the solar cell's position. For practical purposes, data collection is generally conducted every 1 to 5 minutes, as solar intensity does not fluctuate significantly within short intervals. After completing calibration, it is advisable to revert to normal mode by unchecking the calibration box.

In constructing the current-to-voltage converter circuit, it is essential to ensure that the operational amplifiers are configured correctly to maintain accuracy in measurements. The first op-amp should be set up in a non-inverting configuration, where the input current flows through a resistor to produce a voltage drop that is proportional to the current. The feedback resistor value can be adjusted to calibrate the output voltage scale according to the desired current range.

The second op-amp, configured as an inverting amplifier, should have its input connected to the output of the first op-amp, allowing for the inversion of the negative voltage signal. This configuration ensures that the output voltage is suitable for the A/D converter, avoiding any measurement errors due to polarity issues.

The GP-3 board's A/D converter can accurately process the voltage levels generated by the operational amplifiers, enabling effective monitoring of the solar cell's performance. The charting software should be designed to handle incoming data efficiently, providing real-time visualization of the solar power output. This allows for better analysis and understanding of the solar cell's behavior under varying conditions, facilitating further experimentation and optimization of solar tracking systems.

Overall, the combination of the solar cell, current-to-voltage converter circuit, and data visualization software provides a robust platform for exploring solar energy applications and enhancing the efficiency of solar tracking systems.The cell we will use for our solar tracking experiment is made from crystalline silicon and has a maximum voltage rating of. 55V and a maximum current rating of 300 ma. The cell can be picked up in your local Radio Shack for about $5. Although the cell doesn`t produce much power, this experiment can certainly be scaled to handle higher wattages.

Power is the measure of energy per unit time. It can be calculated by multiplying voltage by current at the output of the solar cell. Because our GP-3 Board can only measure voltage, we`ll need to create what is called a current-to-voltage converter circuit. This circuit takes current from the photovoltaic cell and runs it through a couple of operational amplifiers to produce a corresponding voltage (1V corresponds to about 10 milliamps).

Figure 2 shows the circuit constructed for measuring current from the solar cell. The operational amplifier (also known as a differential amplifier) is a great circuit for sensing or measuring just about anything because it keeps the voltage at one input at a reference point determined by the other input. The first opamp is the current-to-voltage converter. It takes the current from the photovoltaic cell and converts it to a voltage determined by the 100 ohm feedback resistor.

Unfortunately the voltage produced at the output of the first opamp is negative (which the A/D channel on our GP-3 board can`t measure). We need to flip the polarity of this voltage using a second op amp set up to invert the voltage sign.

This positive voltage is then fed into pin 10 of our GP-3 board, which is actually channel #0 of our A/D (Analog to Digital) converter. The charting program consists of a User Control that plots data points on an XY Plotter. (See my previous article, An XY Plotter User Control in GDI+ ), a timer control, and the ActiveX control that talks to the GP-3 board.

The program also has buttons that allow you to start and stop charting and a calibration check box to allow you to speed up data collection to test the program. Normally sampling takes place once every minute. In calibration mode sampling is once every second. Figure 3 shows the solar charting form in calibration mode. The output you see was caused by varying the position of the solar cell: To chart the suns power, it is more practical to take data every 1 minute or every 5 minutes because the sun doesn`t change intensity that drastically every second.

So when you are through in calibration mode, switch back to normal mode by clicking the checkbox again and hit t 🔗 External reference