Tilt-meter

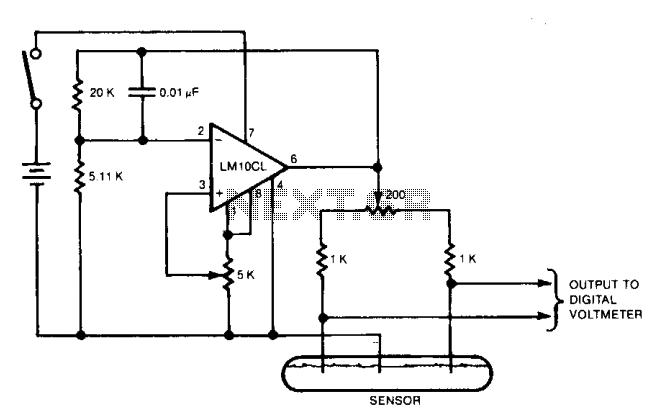

Electrodes are immersed in an electrolyte that maintains a consistent level while the sensor tracks the tilt of the surface it is mounted on. As the tilt occurs, one outer electrode is submerged more deeply than the other, resulting in a decrease in resistance for one and an increase for the other. This variation in resistance leads to a corresponding change in the output voltage of the bridge circuit. The sensor constitutes the two lower legs of the bridge, while two 1000-ohm metal film resistors and a 200-ohm ceramet balance potentiometer form the upper legs. To prepare the device for use, the bridge is balanced by adjusting the balance potentiometer until the bridge output voltage reads zero when the sensor is level. The input voltage to the bridge (DC excitation) is calibrated to yield approximately 10 millivolts of output per degree of tilt, with polarity indicating the direction of the slope. This scaling factor allows a multimeter to display readings directly in degrees, provided the user mentally adjusts the decimal point. Calibration of the scaling factor is performed at various angles to establish the relationship between output voltage and angle.

The described circuit operates based on a Wheatstone bridge configuration, which is commonly used for precise measurement of resistance changes. The two lower legs of the bridge are formed by the electrodes of the sensor, which respond to the tilt by altering their resistances. When the sensor is positioned level, the resistances are equal, and the output voltage of the bridge is zero. However, when tilted, the differential resistance created by the varying immersion of the electrodes results in an unbalanced bridge, producing a measurable output voltage.

The two upper legs consist of two 1000-ohm metal film resistors, known for their precision and stability, ensuring minimal drift over time. The balance potentiometer, rated at 200 ohms, allows fine adjustments to be made to the bridge circuit, facilitating accurate zeroing of the output voltage. The DC excitation voltage supplied to the bridge is critical for determining the sensitivity of the output; in this case, it is set to achieve a 10 millivolt output per degree of tilt, providing a clear and direct correlation between the angle of tilt and the voltage output.

Calibration is an essential step in the setup process. By measuring the output voltage at known angles, a curve can be established that relates the output voltage to the tilt angle. This calibration curve enables users to interpret the multimeter readings accurately, effectively translating voltage measurements into angular displacement. The design ensures that the sensor can be used in various applications requiring precise tilt measurements, such as in automotive systems, robotics, and other fields where orientation is critical.Electrodes are immersed in an electrolyte that remains level while the sensor follows the tilt of the body on which it is placed, more of one outer electrode and less of the other are immersed and their resistances fall or rise, respectively. The resistance change causes a change in the output voltage of the bridge circuit. The sensor forms the two lower legs of the bridge, and two 1000 ohm metal film resistors and a 200 ohm ceremet balance potentiometer form the two upper legs.

In preparation for use, the bridge is balanced by adjusting the balance potentiometer so that the bridge output voltage is zero when the sensor is level. The bridge input voltage (dc excitation) is adjusted to provide about 10 millivolts output per degree of slope, the polarity indicating the sense of the slope. This scaling factor allows the multimeter to read directly in degrees if the user makes a mental shift of the meter decimal point.

The scaling-factor calibration is done at several angles to determine the curve of output voltage versus angle.

The described circuit operates based on a Wheatstone bridge configuration, which is commonly used for precise measurement of resistance changes. The two lower legs of the bridge are formed by the electrodes of the sensor, which respond to the tilt by altering their resistances. When the sensor is positioned level, the resistances are equal, and the output voltage of the bridge is zero. However, when tilted, the differential resistance created by the varying immersion of the electrodes results in an unbalanced bridge, producing a measurable output voltage.

The two upper legs consist of two 1000-ohm metal film resistors, known for their precision and stability, ensuring minimal drift over time. The balance potentiometer, rated at 200 ohms, allows fine adjustments to be made to the bridge circuit, facilitating accurate zeroing of the output voltage. The DC excitation voltage supplied to the bridge is critical for determining the sensitivity of the output; in this case, it is set to achieve a 10 millivolt output per degree of tilt, providing a clear and direct correlation between the angle of tilt and the voltage output.

Calibration is an essential step in the setup process. By measuring the output voltage at known angles, a curve can be established that relates the output voltage to the tilt angle. This calibration curve enables users to interpret the multimeter readings accurately, effectively translating voltage measurements into angular displacement. The design ensures that the sensor can be used in various applications requiring precise tilt measurements, such as in automotive systems, robotics, and other fields where orientation is critical.Electrodes are immersed in an electrolyte that remains level while the sensor follows the tilt of the body on which it is placed, more of one outer electrode and less of the other are immersed and their resistances fall or rise, respectively. The resistance change causes a change in the output voltage of the bridge circuit. The sensor forms the two lower legs of the bridge, and two 1000 ohm metal film resistors and a 200 ohm ceremet balance potentiometer form the two upper legs.

In preparation for use, the bridge is balanced by adjusting the balance potentiometer so that the bridge output voltage is zero when the sensor is level. The bridge input voltage (dc excitation) is adjusted to provide about 10 millivolts output per degree of slope, the polarity indicating the sense of the slope. This scaling factor allows the multimeter to read directly in degrees if the user makes a mental shift of the meter decimal point.

The scaling-factor calibration is done at several angles to determine the curve of output voltage versus angle.