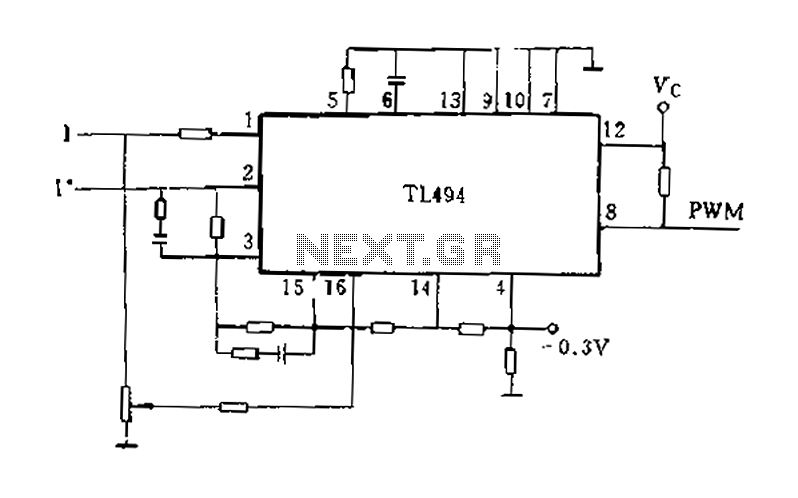

TL494 regulator for the current application

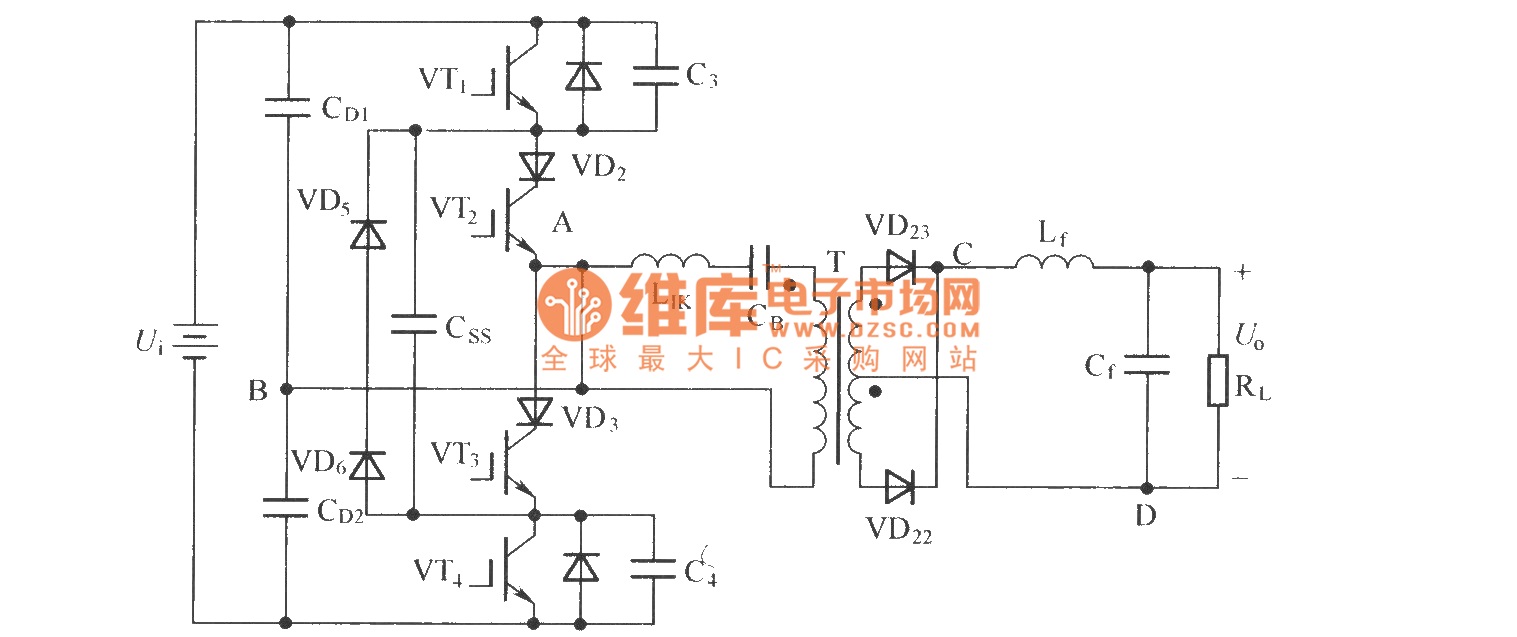

A double-loop speed control system for a brushless DC motor is presented, where the speed controller outputs a torque (or current) signal. The TL494 can be utilized as a current regulator and current limiter. Current feedback is detected from input pin 1, while the command current is received from pin 2. The error amplifier is configured in a PI regulator mode, generating a PWM signal. The comparison method used is serrated ferry crossing, which demonstrates superior performance compared to triangle wave or sawtooth edge methods due to its steep characteristics, effectively minimizing current fluctuations caused by the rapid switching of the PWM signal.

A double-loop speed control system for brushless DC motors is designed to enhance the precision of motor speed regulation. The system employs a speed controller that outputs a torque or current signal to effectively manage the motor's performance. The TL494 integrated circuit serves a dual purpose, functioning both as a current regulator and a current limiter. This dual functionality is critical for maintaining optimal performance and protecting the motor from overcurrent conditions.

In this system, current feedback is monitored through input pin 1, which provides real-time data on the motor's operational status. The command current, which is the desired current level for the motor, is fed into the system via pin 2. An error amplifier is employed to compare the actual current feedback against the command current, generating an error signal that is utilized by the PI (Proportional-Integral) regulator. This regulator adjusts the PWM (Pulse Width Modulation) signal output to minimize the error, thus ensuring that the motor operates at the intended speed.

The PWM signal generated by the PI regulator is crucial for controlling the voltage and current supplied to the motor. To improve the system's response time and stability, the comparison method used for the PWM signal is serrated ferry crossing. This method is preferred over traditional triangle wave or sawtooth edge comparisons because of its steeper characteristics, which significantly reduce the likelihood of current fluctuations during the rapid on-off switching cycles inherent in PWM control. By minimizing these fluctuations, the system enhances the motor's performance, ensuring smoother operation and improved efficiency.

Overall, this comprehensive control system design allows for precise management of brushless DC motors, leveraging advanced feedback mechanisms and innovative comparison techniques to achieve superior control and reliability.DC motor (brushless DC motor) double-loop speed control system, the speed controller output torque (or current) signal given. It can be used TL494 as a current regulator and cu rrent limiter (see Figure 10-3). Current feedback detection signal from the input pin l, the command current J from 2 feet input, the error amplifier is connected to a PI regulator mode, PWM signal. As a comparison here with serrated ferry crossing, the effect is better than the triangle wave, sawtooth edge because the very steep, avoid the fluctuations in current caused by the switching time multiple on-off current PWM signal generating images.

A double-loop speed control system for brushless DC motors is designed to enhance the precision of motor speed regulation. The system employs a speed controller that outputs a torque or current signal to effectively manage the motor's performance. The TL494 integrated circuit serves a dual purpose, functioning both as a current regulator and a current limiter. This dual functionality is critical for maintaining optimal performance and protecting the motor from overcurrent conditions.

In this system, current feedback is monitored through input pin 1, which provides real-time data on the motor's operational status. The command current, which is the desired current level for the motor, is fed into the system via pin 2. An error amplifier is employed to compare the actual current feedback against the command current, generating an error signal that is utilized by the PI (Proportional-Integral) regulator. This regulator adjusts the PWM (Pulse Width Modulation) signal output to minimize the error, thus ensuring that the motor operates at the intended speed.

The PWM signal generated by the PI regulator is crucial for controlling the voltage and current supplied to the motor. To improve the system's response time and stability, the comparison method used for the PWM signal is serrated ferry crossing. This method is preferred over traditional triangle wave or sawtooth edge comparisons because of its steeper characteristics, which significantly reduce the likelihood of current fluctuations during the rapid on-off switching cycles inherent in PWM control. By minimizing these fluctuations, the system enhances the motor's performance, ensuring smoother operation and improved efficiency.

Overall, this comprehensive control system design allows for precise management of brushless DC motors, leveraging advanced feedback mechanisms and innovative comparison techniques to achieve superior control and reliability.DC motor (brushless DC motor) double-loop speed control system, the speed controller output torque (or current) signal given. It can be used TL494 as a current regulator and cu rrent limiter (see Figure 10-3). Current feedback detection signal from the input pin l, the command current J from 2 feet input, the error amplifier is connected to a PI regulator mode, PWM signal. As a comparison here with serrated ferry crossing, the effect is better than the triangle wave, sawtooth edge because the very steep, avoid the fluctuations in current caused by the switching time multiple on-off current PWM signal generating images.