Used for the surface acoustic wave of gas detection shaking circuit design

Due to the small size, high precision, and sensitivity of surface acoustic wave (SAW) sensors, along with their cost-effectiveness, a SAW gas sensor has been developed. This sensor comprises a surface acoustic wave device, a sensitive membrane, and the necessary detection circuit. The sensitive membrane absorbs gaseous substances, and the stress exerted by the examined gas affects the medium in the surface acoustic wave transmission path, altering its dynamic characteristics and consequently changing the resonant frequency of the surface acoustic wave device. This variation is detected by the related circuit, influencing the measurement of the gas properties and the technical indicators such as precision and accuracy of the entire sensor, which are directly affected by the characteristics of the detection circuit. Therefore, circuit design is a crucial aspect of the SAW gas sensor. The surface acoustic wave device employs a resonator or delay line for frequency stabilization. Typically, these devices are made from stable single crystal quartz, ensuring a steady frequency output. The fundamental operating frequency of the surface acoustic wave oscillator can reach up to 2000 MHz, differing from traditional low-frequency acoustic wave oscillators in terms of weight, size, power consumption, cost, and reliability. The surface acoustic wave oscillator serves as the response element of the sensor, with its definition, stability, and precision directly influencing the frequency stability of the sensor. The oscillating frequency is determined when the phase of the feedback loop is zero, thus enhancing the frequency stability of the surface acoustic wave oscillator improves the sensor's performance. The surface acoustic wave device utilizes a fork structure that exhibits excellent frequency selectivity, achieved by accurately designing the bilateral interdigital transducer through processes like lithography. The surface acoustic wave resonator (SAWR) is a high Q-factor resonator similar to quartz crystal resonators in many aspects. In comparison to the surface acoustic wave delay line (SAWDL) shaker, the transmission characteristics of the double-pointed resonator exhibit similarities to high Q-factor and delay characteristics, with several distinguishing features: first, the resonator's size is very small; second, the insertion loss is significantly lower; and third, while the frequency modulation range is narrower than that of the delay line, the stability of the frequency modulation range is reduced. For sensors based on resonant SAW devices, the frequency stability of the base curve is a critical technical indicator. In surface acoustic wave gas sensors, a sensitive membrane is added to the SAW device, which increases the insertion loss. Excessive insertion loss can decrease stability, hence it is important to minimize the insertion loss of the SAW device. Surface acoustic wave resonators can be categorized into single-end resonators and double-pointed resonators based on the configuration of the interdigital transducer, with each type exhibiting unique characteristics.

The SAW gas sensor is designed to detect specific gaseous substances with high sensitivity and accuracy. The core component, the surface acoustic wave device, operates by generating acoustic waves that travel along the surface of the material. When a gas interacts with the sensitive membrane, it alters the mechanical stress on the surface, leading to changes in the acoustic wave propagation characteristics. This interaction is quantified by monitoring the resonant frequency shifts that occur as a result of the gas absorption.

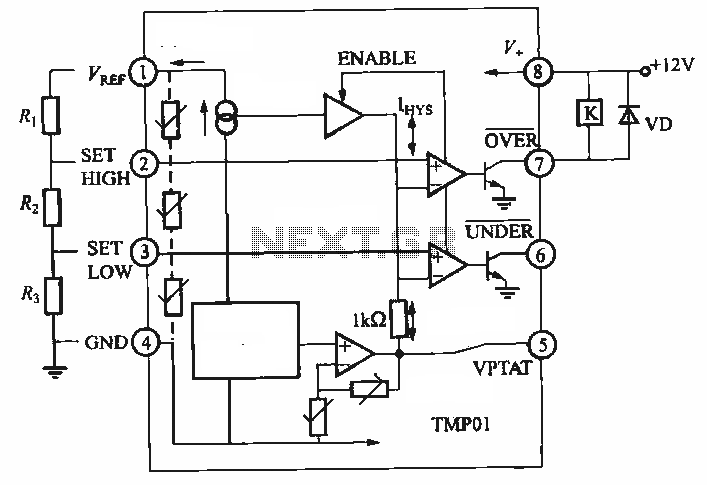

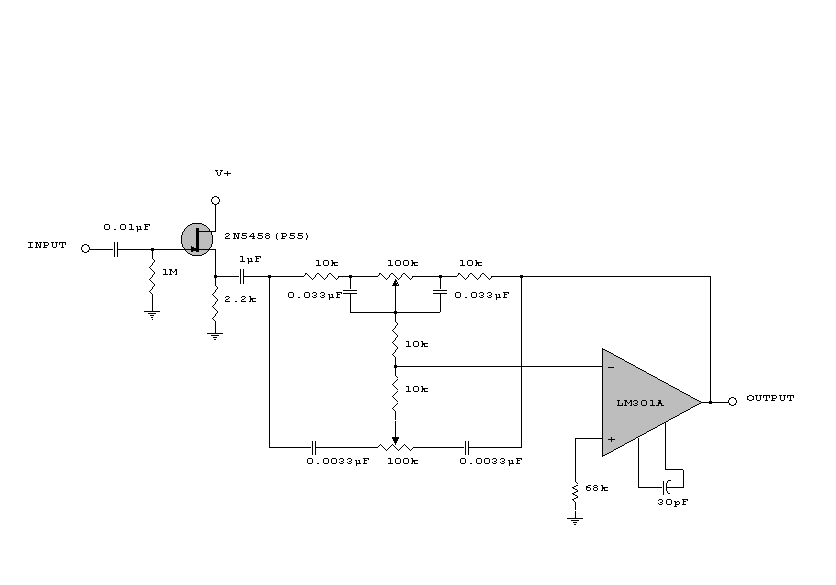

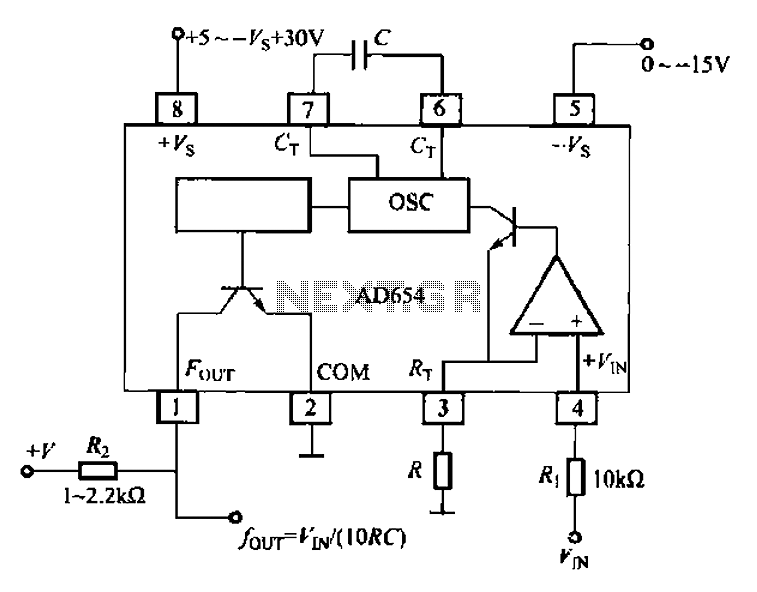

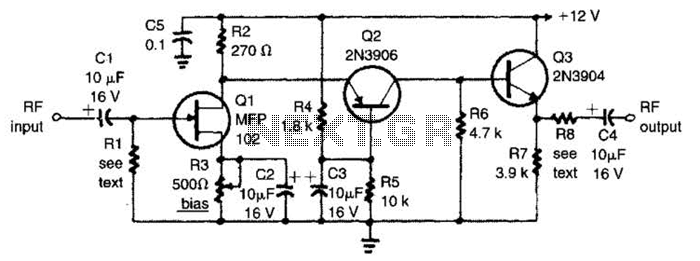

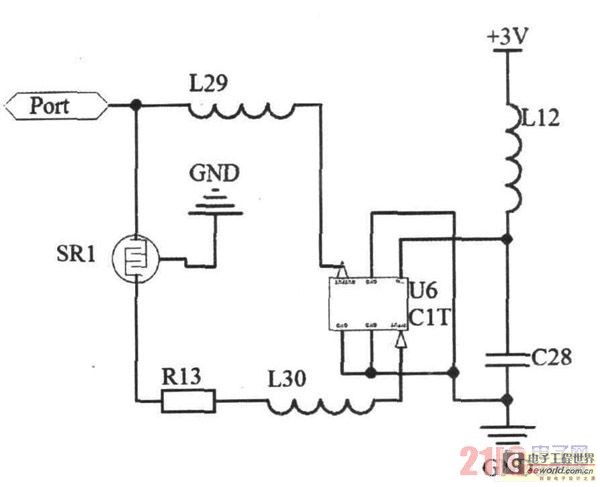

To ensure optimal performance, the design of the detection circuit is tailored to accurately measure these frequency changes. The circuit typically includes components such as amplifiers, filters, and analog-to-digital converters to process the signals generated by the SAW device. The choice of materials and components in the circuit design directly impacts the sensor's overall performance, including its sensitivity, response time, and stability.

The SAW device's construction, particularly the use of high-quality single crystal quartz, contributes to its frequency stability and low insertion loss. The design of the interdigital transducer is critical, as it defines the frequency selectivity and overall efficiency of the SAW device. The resonator's small size and low insertion loss make it particularly suitable for portable applications where space and power consumption are limited.

In summary, the SAW gas sensor represents a significant advancement in gas detection technology, combining high sensitivity and precision with compact size and cost-effectiveness. Its performance is heavily reliant on the intricate design of both the SAW device and the associated detection circuit, making it a versatile tool for various applications in environmental monitoring, industrial safety, and medical diagnostics.Because small, precision high, high sensitivity and definition higher advantage with low price of having size of SAW sensor, so has produced SAW gas sensor composed of surface acoustic wave device, sensitive membrane and relevant detection circuit. The sensitive membrane is in the course of absorbing gaseously, the stress that the gas examined causes is acted on the medium in the surface

acoustic wave transmission path, make its characteristic of dynamics change, and then change the resonant frequency of the surface acoustic wave device. This variation happens in the detection circuit test related to it, thus the gaseous relation property of awaiting measuring, and technical indicators such as precision and accuracy grade of the whole sensor of direct influence of relevant characteristic of the detection circuit, etc.

So, the design of the circuit is an essential link in SAW gas sensor. Surface acoustic wave SAW The Shaker uses surface acoustic wave resonator or delay cable as the frequency stabilization component to form. The surface acoustic wave device usually adopts the stable single crystal quartz material of characteristic to be made, the frequency outputted is very steady.

The fundamental operating frequency of the sound surface wave oscillator is high, the operating range is very high to 2000MH z, body of low frequency acoustic wave oscillator different relatively with traditional adoption, have the intersection of weight and light, the intersection of volume and little, the intersection of power consumption and little, low cost, the intersection of reliability and the intersection of increase, etc. and advantage. The sound surface wave oscillator is regarded as the response element of the surface acoustic wave sensor, definition, stability and testing the precision of its direct influence sensor of frequency stability, its oscillating frequency depends on the condition when the phase place of feedback loop is zero.

So the improvement of the sound surface wave oscillator frequency stability contributes to further improving the performance index of the sensor. Surface acoustic wave SAW The device is that one kind adopts the fork to mean the device that structural frequency selectivity is very good, after through designing the fork of the bilateral interdigital transducer to refer to logarithm and interval accurately, and then make by evaporating crafts such as litho, etc.

Surface acoustic wave resonator SAWR It is a resonator of a kind of high q-factor, are similar to quartz crystal resonator in many aspects. And surface acoustic wave delay line SAWDL The Shaker is compared, the transmission characteristic of the double-pointed resonator is similar to high q-factor and delay the collinear characteristic, but it has the following several to show the characteristic: First, the size of the resonator is very small; Second, the insertion loss of the resonator is much smaller; Third, the frequency modulation range of the resonator is narrower than the delay cable, but the simultaneous stability that the frequency modulation range increases will be reduced.

To sensor based on resonant SAW device, the frequency stability of base curve is one of the most important technical indicators. As to the gas sensor of surface acoustic wave, need to add the sensitive membrane on the device of the saw, in this way, will increase the insertion loss of the device, too big insertion loss will reduce stability, so the insertion loss of SAW device can`t be big.

The surface acoustic wave resonator can be divided into two kinds single-end resonators and double-pointed resonators according to the logarithm of the interdigital transducer too. The resonators of these two kinds of types each have a characteristic, the surface acoustic wave resonator r

🔗 External reference

The SAW gas sensor is designed to detect specific gaseous substances with high sensitivity and accuracy. The core component, the surface acoustic wave device, operates by generating acoustic waves that travel along the surface of the material. When a gas interacts with the sensitive membrane, it alters the mechanical stress on the surface, leading to changes in the acoustic wave propagation characteristics. This interaction is quantified by monitoring the resonant frequency shifts that occur as a result of the gas absorption.

To ensure optimal performance, the design of the detection circuit is tailored to accurately measure these frequency changes. The circuit typically includes components such as amplifiers, filters, and analog-to-digital converters to process the signals generated by the SAW device. The choice of materials and components in the circuit design directly impacts the sensor's overall performance, including its sensitivity, response time, and stability.

The SAW device's construction, particularly the use of high-quality single crystal quartz, contributes to its frequency stability and low insertion loss. The design of the interdigital transducer is critical, as it defines the frequency selectivity and overall efficiency of the SAW device. The resonator's small size and low insertion loss make it particularly suitable for portable applications where space and power consumption are limited.

In summary, the SAW gas sensor represents a significant advancement in gas detection technology, combining high sensitivity and precision with compact size and cost-effectiveness. Its performance is heavily reliant on the intricate design of both the SAW device and the associated detection circuit, making it a versatile tool for various applications in environmental monitoring, industrial safety, and medical diagnostics.Because small, precision high, high sensitivity and definition higher advantage with low price of having size of SAW sensor, so has produced SAW gas sensor composed of surface acoustic wave device, sensitive membrane and relevant detection circuit. The sensitive membrane is in the course of absorbing gaseously, the stress that the gas examined causes is acted on the medium in the surface

acoustic wave transmission path, make its characteristic of dynamics change, and then change the resonant frequency of the surface acoustic wave device. This variation happens in the detection circuit test related to it, thus the gaseous relation property of awaiting measuring, and technical indicators such as precision and accuracy grade of the whole sensor of direct influence of relevant characteristic of the detection circuit, etc.

So, the design of the circuit is an essential link in SAW gas sensor. Surface acoustic wave SAW The Shaker uses surface acoustic wave resonator or delay cable as the frequency stabilization component to form. The surface acoustic wave device usually adopts the stable single crystal quartz material of characteristic to be made, the frequency outputted is very steady.

The fundamental operating frequency of the sound surface wave oscillator is high, the operating range is very high to 2000MH z, body of low frequency acoustic wave oscillator different relatively with traditional adoption, have the intersection of weight and light, the intersection of volume and little, the intersection of power consumption and little, low cost, the intersection of reliability and the intersection of increase, etc. and advantage. The sound surface wave oscillator is regarded as the response element of the surface acoustic wave sensor, definition, stability and testing the precision of its direct influence sensor of frequency stability, its oscillating frequency depends on the condition when the phase place of feedback loop is zero.

So the improvement of the sound surface wave oscillator frequency stability contributes to further improving the performance index of the sensor. Surface acoustic wave SAW The device is that one kind adopts the fork to mean the device that structural frequency selectivity is very good, after through designing the fork of the bilateral interdigital transducer to refer to logarithm and interval accurately, and then make by evaporating crafts such as litho, etc.

Surface acoustic wave resonator SAWR It is a resonator of a kind of high q-factor, are similar to quartz crystal resonator in many aspects. And surface acoustic wave delay line SAWDL The Shaker is compared, the transmission characteristic of the double-pointed resonator is similar to high q-factor and delay the collinear characteristic, but it has the following several to show the characteristic: First, the size of the resonator is very small; Second, the insertion loss of the resonator is much smaller; Third, the frequency modulation range of the resonator is narrower than the delay cable, but the simultaneous stability that the frequency modulation range increases will be reduced.

To sensor based on resonant SAW device, the frequency stability of base curve is one of the most important technical indicators. As to the gas sensor of surface acoustic wave, need to add the sensitive membrane on the device of the saw, in this way, will increase the insertion loss of the device, too big insertion loss will reduce stability, so the insertion loss of SAW device can`t be big.

The surface acoustic wave resonator can be divided into two kinds single-end resonators and double-pointed resonators according to the logarithm of the interdigital transducer too. The resonators of these two kinds of types each have a characteristic, the surface acoustic wave resonator r

🔗 External reference