VALVE BASICS

Observing the bottom of a valve reveals the wires connected to each electrode and the valve base pins. Therefore, specific valve data or pin-outs will not be provided, as this information is widely accessible from various sources, and most pin-outs can be visually determined. The term "DIODE" may seem misleading, as it consists of only two electrodes; a more fitting name could be "BIODE." Essentially, when a cathode electrode is placed in a vacuum, coated with Barium Oxide, and heated to several hundred degrees, the electrons on its surface become agitated, forming a cloud around the cathode. This electron cloud allows for easy attraction of electrons to a positively charged electrode, known as the anode. The anode must be situated in the same vacuum as the cathode. Electrons will flow from the heated cathode to the relatively cooler anode, but not in the reverse direction due to the absence of Barium Oxide coating on the anode and its low temperature. This configuration forms a DIODE valve. The circuit symbols indicate that the cathode consists of a filament wire coated with Barium Oxide, through which current is passed to produce heat. One of the two filament terminals serves as the cathode connection. This heating method was commonly used in battery-operated equipment and high-tension (HT) rectifier valves. The filament voltage for battery valves typically measures 1.4 volts, as seen in models such as 1T4, 1L4, 1S4, DF91, and DL91. Directly heated HT rectifier valves usually require 5 volts for heating, while early valves operated at 2.5 volts. A significant drawback of a directly heated diode is that the current flowing from the cathode to the anode adds to the filament current. If this combined current exceeds safe levels, the filament may overheat and burn out, similar to an overloaded bulb. The non-coated filament wire is placed inside a Barium Oxide-coated metal tube, insulated from it. The filament's sole purpose is to heat the cathode tube, thus it is referred to as the HEATER. A typical diode valve construction is illustrated, with (A) showing a filament wire supported by a wire hook, which may also serve as a direct electrical connection to the filament wire, acting as a center-tap for the cathode connection. Center-tapped filaments generally operate at 2.8 volts, with 1.4 volts between the center-tap and each filament connection. (B) depicts a typical indirectly heated cathode, while (C) shows the anode assembled around the cathode, which can be circular or take various shapes. The diode valve has advantages over semiconductor diodes, as the latter requires a specific voltage across its terminals to initiate conduction. In contrast, the vacuum tube diode does not have this limitation, making it an ideal and sensitive RF/IF detector. Semiconductors can fail in microseconds, while valves may endure several seconds before experiencing issues, indicating that valves are more forgiving than transistors. To create an amplifying device and prevent catastrophic failure, it is necessary to regulate the current flowing from the cathode to the anode of a valve. Introducing a wire mesh or GRID between the anode and cathode allows for control over electron flow, resulting in a TRIODE configuration. This grid is designated as the CONTROL GRID. With a few hundred volts positive on the ANODE and negative on the cathode, electrons from the cloud surrounding the heated cathode can be effectively managed.

The operation of a diode valve is fundamentally based on thermionic emission, where the heated cathode releases electrons into the vacuum. The electrons are attracted to the positively charged anode, which is essential for the diode's functionality. The construction of the valve ensures that the cathode is adequately heated, typically by a filament or heater, which is crucial for maintaining the thermionic emission process.

In practical applications, the diode valve serves as a rectifier, converting alternating current (AC) to direct current (DC). Its ability to conduct current in one direction while blocking it in the opposite direction is the key characteristic that enables this function. The efficiency and reliability of diode valves in high-frequency applications make them valuable components in radio frequency (RF) circuits, where they can serve as detectors or amplifiers.

When transitioning to a triode, the introduction of the control grid allows for modulation of the electron flow between the cathode and anode. This modulation is critical for amplifying signals, as varying the voltage on the control grid can influence the number of electrons that reach the anode, thereby controlling the output current. This principle forms the basis for many amplification applications in audio and radio frequency technologies.

The design considerations for these components include the choice of materials for the electrodes, the vacuum quality within the valve, and the thermal management of the filament. These factors directly impact the performance, longevity, and efficiency of the valve in various circuit applications.If you look into the bottom of a valve you will see the wires from each electrode and you can see the valve base pins to which they are connected. For this reason I will not give any valve data or pin-outs. These are widely available from other sources and most pin-outs can be worked out visually. I do not know why it is called a DIODE. With only two electrodes I reckon it should be called a BIODE. Basically, when an electrode (CATHODE) is placed in a vacuum, coated with Barium Oxide and heated to several hundred degrees, the electrons on its surface become more agitated and form a cloud around the cathode`s surface. From this cloud of electrons it is easy to attract electrons to a positively charged electrode (ANODE).

The anode only needs to be placed in the same vacuum as the cathode. Electrons will flow from the heated cathode to the relatively cool anode, but electrons will NOT flow from the anode to the cathode because there is no Barium Oxide coating on the anode and it is too cold. We have formed a DIODE valve. Here are the circuit symbols. The cathode is a bit of filament wire coated with Barium Oxide and a current is passed through it to make it get hot.

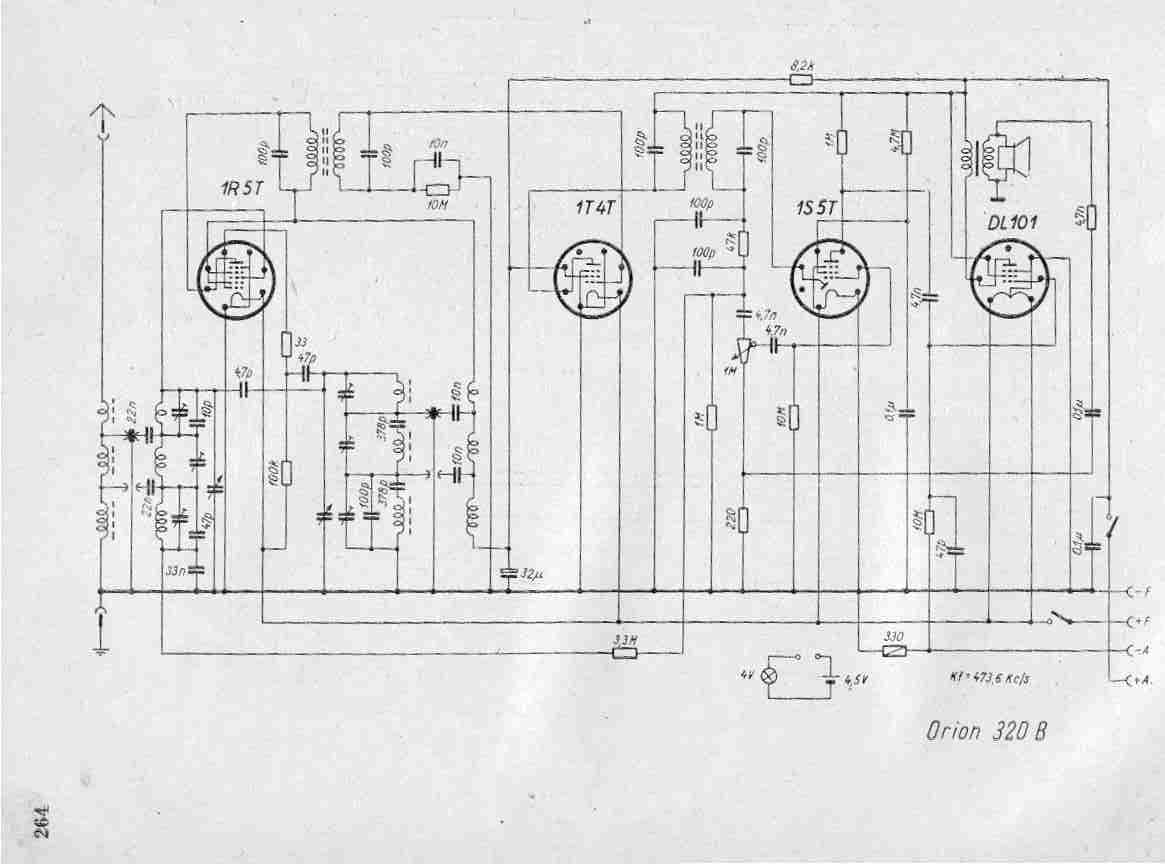

One of the two filament terminals is used as the cathode connection. This method of heating a valve cathode was most often used in battery portable equipment and HT rectifier valves. The filament voltage is normally 1. 4 volts for battery valves such as 1T4, 1L4, 1S4, DF91, DL91 etc. Directly heated HT rectifier valves commonly used 5 volts to heat them. Early valves used only 2. 5 volts for the filament. A huge disadvantage of a directly heated diode is that current flowing from cathode to anode is added to the filament current.

If this current becomes too large then the filament can become too hot and burn out, just like an overloaded torch-bulb. The non-coated filament wire is inserted into a Barium Oxide coated metal tube and insulated from it.

The filament is only used to heat the cathode tube and so it is normally called the HEATER. Here you can see a typical diode valve construction. (A) shows a typical filament wire with a wire support hook. Some valves use the wire support hook to make a direct electrical connection to the filament wire. This connection is used as a centre-tap for the cathode connection. Centre-tapped filaments are usually 2. 8 volts; 1. 4 volts between the centre-tap and each filament connection. (B) shows a typical indirectly heated cathode. (C) shows the anode assembled around the cathode. The anode may be circular or a variety of weird shapes. The diode valve is in many ways far superior to semiconductor diode because a semiconductor diode requires a certain voltage across its terminals before it begins to conduct. The vacuum tube diode does not suffer from this effect, making it an ideal and sensitive RF/IF detector.

Semiconductors will blow in microseconds whereas valves may last several seconds before something happens. In this way valves are more forgiving than transistors. To make an amplifying device (and to prevent the catastrophic scenario above) we need to regulate the current flowing from the cathode to the anode of a valve.

If we insert a wire mesh or GRID between the anode and the cathode we can control the electron flow and so we have created a TRIODE: This grid is called the CONTROL GRID. With a few hundred volts positive on the ANODE and the negative on the cathode, electrons from the electron cloud around the heated cathode w

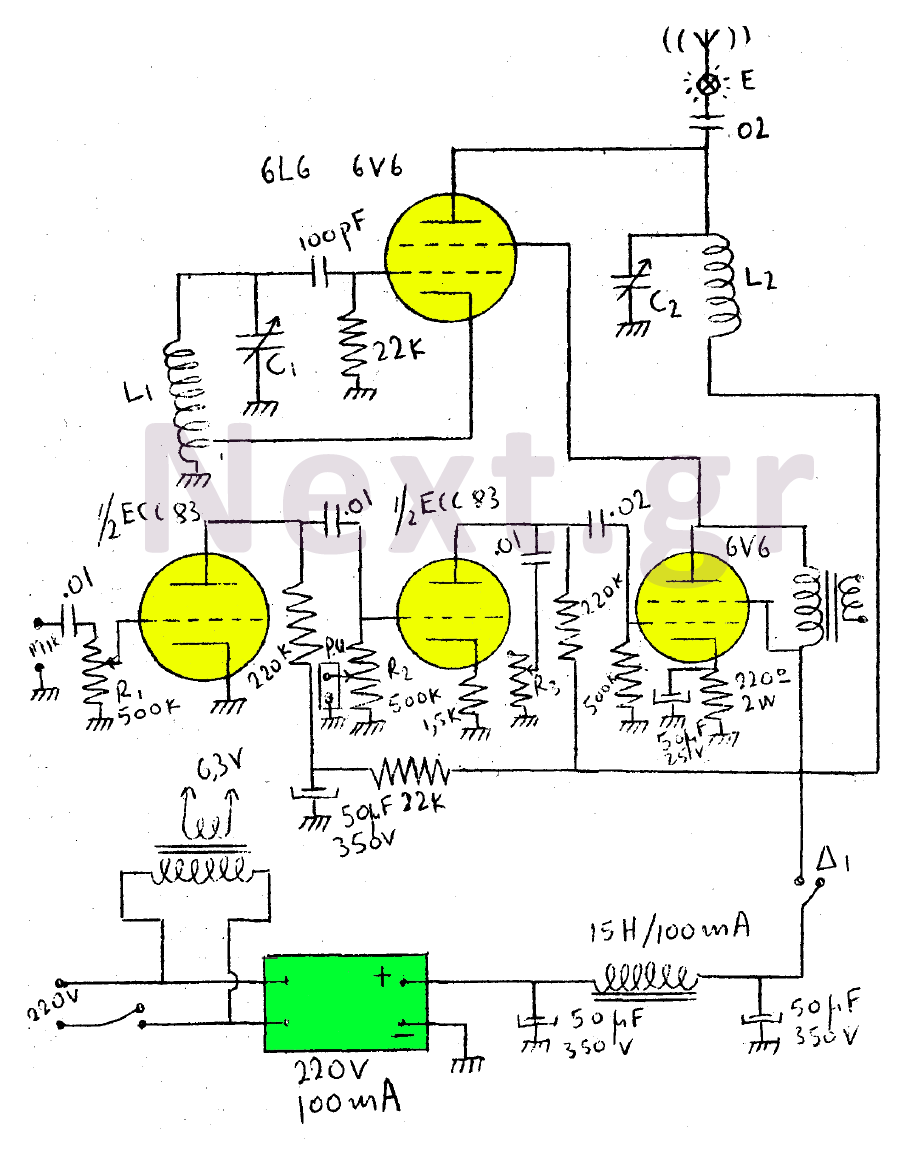

🔗 External reference

The operation of a diode valve is fundamentally based on thermionic emission, where the heated cathode releases electrons into the vacuum. The electrons are attracted to the positively charged anode, which is essential for the diode's functionality. The construction of the valve ensures that the cathode is adequately heated, typically by a filament or heater, which is crucial for maintaining the thermionic emission process.

In practical applications, the diode valve serves as a rectifier, converting alternating current (AC) to direct current (DC). Its ability to conduct current in one direction while blocking it in the opposite direction is the key characteristic that enables this function. The efficiency and reliability of diode valves in high-frequency applications make them valuable components in radio frequency (RF) circuits, where they can serve as detectors or amplifiers.

When transitioning to a triode, the introduction of the control grid allows for modulation of the electron flow between the cathode and anode. This modulation is critical for amplifying signals, as varying the voltage on the control grid can influence the number of electrons that reach the anode, thereby controlling the output current. This principle forms the basis for many amplification applications in audio and radio frequency technologies.

The design considerations for these components include the choice of materials for the electrodes, the vacuum quality within the valve, and the thermal management of the filament. These factors directly impact the performance, longevity, and efficiency of the valve in various circuit applications.If you look into the bottom of a valve you will see the wires from each electrode and you can see the valve base pins to which they are connected. For this reason I will not give any valve data or pin-outs. These are widely available from other sources and most pin-outs can be worked out visually. I do not know why it is called a DIODE. With only two electrodes I reckon it should be called a BIODE. Basically, when an electrode (CATHODE) is placed in a vacuum, coated with Barium Oxide and heated to several hundred degrees, the electrons on its surface become more agitated and form a cloud around the cathode`s surface. From this cloud of electrons it is easy to attract electrons to a positively charged electrode (ANODE).

The anode only needs to be placed in the same vacuum as the cathode. Electrons will flow from the heated cathode to the relatively cool anode, but electrons will NOT flow from the anode to the cathode because there is no Barium Oxide coating on the anode and it is too cold. We have formed a DIODE valve. Here are the circuit symbols. The cathode is a bit of filament wire coated with Barium Oxide and a current is passed through it to make it get hot.

One of the two filament terminals is used as the cathode connection. This method of heating a valve cathode was most often used in battery portable equipment and HT rectifier valves. The filament voltage is normally 1. 4 volts for battery valves such as 1T4, 1L4, 1S4, DF91, DL91 etc. Directly heated HT rectifier valves commonly used 5 volts to heat them. Early valves used only 2. 5 volts for the filament. A huge disadvantage of a directly heated diode is that current flowing from cathode to anode is added to the filament current.

If this current becomes too large then the filament can become too hot and burn out, just like an overloaded torch-bulb. The non-coated filament wire is inserted into a Barium Oxide coated metal tube and insulated from it.

The filament is only used to heat the cathode tube and so it is normally called the HEATER. Here you can see a typical diode valve construction. (A) shows a typical filament wire with a wire support hook. Some valves use the wire support hook to make a direct electrical connection to the filament wire. This connection is used as a centre-tap for the cathode connection. Centre-tapped filaments are usually 2. 8 volts; 1. 4 volts between the centre-tap and each filament connection. (B) shows a typical indirectly heated cathode. (C) shows the anode assembled around the cathode. The anode may be circular or a variety of weird shapes. The diode valve is in many ways far superior to semiconductor diode because a semiconductor diode requires a certain voltage across its terminals before it begins to conduct. The vacuum tube diode does not suffer from this effect, making it an ideal and sensitive RF/IF detector.

Semiconductors will blow in microseconds whereas valves may last several seconds before something happens. In this way valves are more forgiving than transistors. To make an amplifying device (and to prevent the catastrophic scenario above) we need to regulate the current flowing from the cathode to the anode of a valve.

If we insert a wire mesh or GRID between the anode and the cathode we can control the electron flow and so we have created a TRIODE: This grid is called the CONTROL GRID. With a few hundred volts positive on the ANODE and the negative on the cathode, electrons from the electron cloud around the heated cathode w

🔗 External reference