555 boost converter

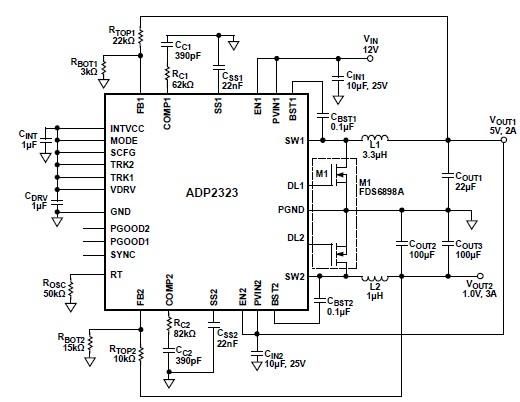

Boost circuits are an effective method for powering microcontrollers. Rather than using multiple AA batteries or a 9V battery (which is typically regulated down to 5V or 3.3V), one can boost the voltage from one or two AA batteries to the required level. The main challenges are that boost integrated circuits (ICs) can become costly when producing more than two or three units, and the more affordable options are often difficult to find in hand-solderable packages. A potential solution involves utilizing pulse-width modulation (PWM) from a microcontroller. The Atmel ATtiny43U has introduced a built-in boost converter, which may set a trend for future microcontrollers to include such features, similar to their support for serial, I2C, and SPI protocols. In the interim, a simpler solution could involve a boost converter using a 555 timer. The 555 timer is a widely available and inexpensive chip that can generate PWM at a specified frequency and duty cycle, determined by external resistors and a capacitor. The circuit would require basic components typical of a boost converter (inductor, diode, capacitor), but at a lower cost. However, it would not regulate voltage, only amplify it based on a calculated duty cycle, which presents limitations since the voltage of an AA battery fluctuates over its lifespan. Despite these constraints, there are applications where generating approximately 5V from a single AA or AAA battery is beneficial, such as powering servos in a kite aerial photography setup. Wikipedia provides a comprehensive explanation of boost converter functionality. The fundamental principle involves passing the source voltage through an inductor, which alternately connects to ground via a transistor and disconnects to charge the capacitor. The duty cycle, defined by the ratio of connection time to disconnection time, dictates the boosted voltage. The formula D = 1 Vi/(Vo + 0.5) calculates the necessary duty cycle, with the +0.5 accounting for the diode's forward voltage. Online 555 timer calculators assist in selecting resistors and capacitors based on the duty cycle, and as long as the frequency is in the kilohertz range, the circuit should operate effectively. However, performance diminishes significantly when a load is attached, resulting in a substantial voltage drop. While higher frequencies may provide minor improvements, they are insufficient. A higher duty cycle is necessary to accommodate the load, a function typically handled by a boost converter, but the fixed frequency and duty cycle of the 555 timer limit its effectiveness. If the load remains constant, such as in powering a string of LEDs, the duty cycle can be adjusted to achieve the desired voltage under those conditions. Otherwise, the circuit is primarily useful for charging a capacitor. In scenarios where a 1.5V AAA battery needs to be boosted to 12V or even 50V for a brief discharge, this circuit may suffice, albeit with caution. However, the 555 timer's inability to dynamically adjust the duty cycle renders it less practical for boost conversion, suggesting that exploring inexpensive PWM controllers may be a more viable option.

Boost circuits serve as a practical solution for powering microcontrollers by increasing voltage from low-voltage battery sources. These circuits typically employ boost converters, which can be integrated into microcontrollers or implemented using discrete components. The Atmel ATtiny43U exemplifies the trend of integrating boost converters into microcontroller designs, allowing for simplified power management and enhanced functionality.

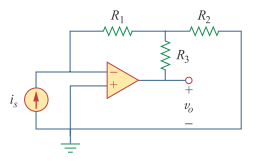

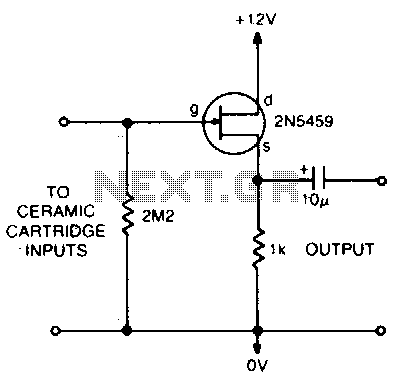

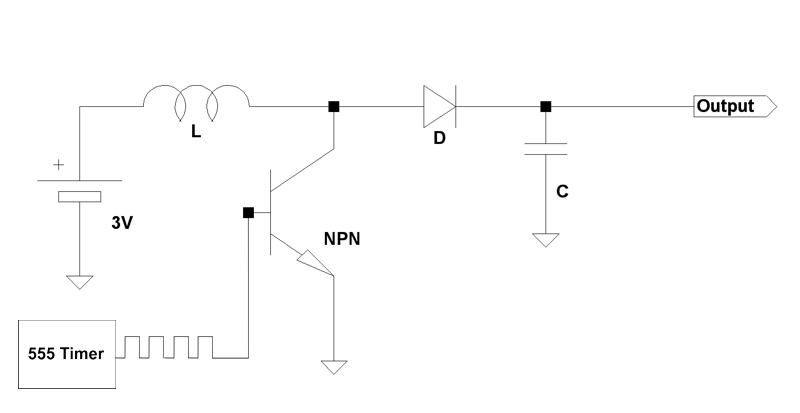

The 555 timer configuration presents a low-cost alternative for generating PWM signals to drive a boost converter. The 555 timer operates in astable mode, producing a square wave output that can be used to control the switching of a transistor, which in turn regulates the flow of current through an inductor. The inductor stores energy when the transistor is on and releases it to the load through a diode when the transistor is off, effectively increasing the voltage supplied to the load.

Key components of a basic boost converter circuit using a 555 timer include:

1. **555 Timer**: Configured to generate PWM signals. The frequency and duty cycle can be adjusted using external resistors and capacitors.

2. **Inductor**: Stores energy during the "on" phase of the PWM signal, which is crucial for boosting voltage.

3. **Diode**: Prevents backflow of current and allows the inductor's stored energy to charge the output capacitor.

4. **Output Capacitor**: Smooths the output voltage to provide a stable power supply to the load.

The performance of this circuit is contingent on the selection of components and the load characteristics. While the 555 timer provides a simple means of generating PWM, the inability to dynamically adjust the duty cycle in response to varying loads limits its application in scenarios where load conditions change frequently. For static loads, such as LED strings, the circuit can be optimized to achieve the desired output voltage.

In conclusion, while the 555 timer-based boost converter offers a low-cost solution for specific applications, its limitations in voltage regulation and dynamic response to load variations suggest that alternative PWM controllers may be more suitable for applications requiring robust performance and adaptability.Boost circuits are an awesome way to power microcontrollers. Instead of 4AA batteries or a 9V (usually regulated down to 5V or 3. 3V), you just boost one or two AA`s up to your desired voltage. The only problems are that boost ICs (like these two ) are a little expensive once you decide to make more than 2 or 3 of something, and the cheaper ones ar e hard to find in packages that can be hand soldered easily. I stumbled upon one great solution here use PWM from a microcontroller. And Atmel recently introduced the ATtiny43U with a built-in boost converter hopefully this will become a trend and all microcontrollers will come with built-in boost converters, the same way they (mostly) all support serial, I2C, and SPI. But in the meantime I wondered if a simpler solution might be possible, a boost converter using a 555 timer.

The 555 timer is a very common $0. 20 chip that can generate a PWM at a given frequency and duty cycle based on the charge time of some chosen resistors and a capacitor. The circuit would need the same basic external components as a boost converter (inductor, diode, capacitor), but it would be a lot cheaper.

It wouldn`t be able to regulate the voltage, only multiply it using a calculated duty cycle, so the solution already starts off a bit limited since the voltage of a AA battery varies over it`s lifetime. But despite this limitation, there are definitely applications where providing roughly 5V from a single AA or AAA is very useful (powering servos in a kite aerial photography rig, for example) Wikipedia has a great explanation of how a boost converter works.

The basic idea is that the source voltage is run through an inductor and alternately connected to ground through the transistor and disconnected so that it will charge the capacitor. The ratio of how long it`s connected to ground and how long it`s disconnected is the duty cycle, which determines the boosted voltage.

The math is pretty simple: D = 1 Vi/(Vo+0. 5) gives you the duty cycle you`ll need (the +0. 5 part is to compensate for the forward voltage of the diode). 555 timer calculators are available all over the Internet for choosing resistors and capacitor based on the duty cycle. As long as the frequency is in the KHz it should work. And when wired up it does work great until you attach a load, then the voltage drops precipitously. Higher frequencies seem to help a bit, but not enough. A higher duty cycle is needed to compensate for the load, which is how a boost converter handles the problem, but our simple 555 timer with its constant frequency and duty cycle is not up to the task.

If the load never varies powering a string of LEDs, for example - then you can play with the duty cycle to get the voltage you need under those conditions. Other than that, the only thing it`s useful for is charging a capacitor. If you wanted to boost a 1. 5V AAA battery up to 12V or 50V and release it all at once, this circuit can get it done. Use it to shock your cat. So a 555 timer isn`t very useful for a boost converter because there`s no easy way to adjust the duty cycle on-the-fly.

But inexpensive PWM controllers do exist perhaps I`ll try that next. 🔗 External reference

Boost circuits serve as a practical solution for powering microcontrollers by increasing voltage from low-voltage battery sources. These circuits typically employ boost converters, which can be integrated into microcontrollers or implemented using discrete components. The Atmel ATtiny43U exemplifies the trend of integrating boost converters into microcontroller designs, allowing for simplified power management and enhanced functionality.

The 555 timer configuration presents a low-cost alternative for generating PWM signals to drive a boost converter. The 555 timer operates in astable mode, producing a square wave output that can be used to control the switching of a transistor, which in turn regulates the flow of current through an inductor. The inductor stores energy when the transistor is on and releases it to the load through a diode when the transistor is off, effectively increasing the voltage supplied to the load.

Key components of a basic boost converter circuit using a 555 timer include:

1. **555 Timer**: Configured to generate PWM signals. The frequency and duty cycle can be adjusted using external resistors and capacitors.

2. **Inductor**: Stores energy during the "on" phase of the PWM signal, which is crucial for boosting voltage.

3. **Diode**: Prevents backflow of current and allows the inductor's stored energy to charge the output capacitor.

4. **Output Capacitor**: Smooths the output voltage to provide a stable power supply to the load.

The performance of this circuit is contingent on the selection of components and the load characteristics. While the 555 timer provides a simple means of generating PWM, the inability to dynamically adjust the duty cycle in response to varying loads limits its application in scenarios where load conditions change frequently. For static loads, such as LED strings, the circuit can be optimized to achieve the desired output voltage.

In conclusion, while the 555 timer-based boost converter offers a low-cost solution for specific applications, its limitations in voltage regulation and dynamic response to load variations suggest that alternative PWM controllers may be more suitable for applications requiring robust performance and adaptability.Boost circuits are an awesome way to power microcontrollers. Instead of 4AA batteries or a 9V (usually regulated down to 5V or 3. 3V), you just boost one or two AA`s up to your desired voltage. The only problems are that boost ICs (like these two ) are a little expensive once you decide to make more than 2 or 3 of something, and the cheaper ones ar e hard to find in packages that can be hand soldered easily. I stumbled upon one great solution here use PWM from a microcontroller. And Atmel recently introduced the ATtiny43U with a built-in boost converter hopefully this will become a trend and all microcontrollers will come with built-in boost converters, the same way they (mostly) all support serial, I2C, and SPI. But in the meantime I wondered if a simpler solution might be possible, a boost converter using a 555 timer.

The 555 timer is a very common $0. 20 chip that can generate a PWM at a given frequency and duty cycle based on the charge time of some chosen resistors and a capacitor. The circuit would need the same basic external components as a boost converter (inductor, diode, capacitor), but it would be a lot cheaper.

It wouldn`t be able to regulate the voltage, only multiply it using a calculated duty cycle, so the solution already starts off a bit limited since the voltage of a AA battery varies over it`s lifetime. But despite this limitation, there are definitely applications where providing roughly 5V from a single AA or AAA is very useful (powering servos in a kite aerial photography rig, for example) Wikipedia has a great explanation of how a boost converter works.

The basic idea is that the source voltage is run through an inductor and alternately connected to ground through the transistor and disconnected so that it will charge the capacitor. The ratio of how long it`s connected to ground and how long it`s disconnected is the duty cycle, which determines the boosted voltage.

The math is pretty simple: D = 1 Vi/(Vo+0. 5) gives you the duty cycle you`ll need (the +0. 5 part is to compensate for the forward voltage of the diode). 555 timer calculators are available all over the Internet for choosing resistors and capacitor based on the duty cycle. As long as the frequency is in the KHz it should work. And when wired up it does work great until you attach a load, then the voltage drops precipitously. Higher frequencies seem to help a bit, but not enough. A higher duty cycle is needed to compensate for the load, which is how a boost converter handles the problem, but our simple 555 timer with its constant frequency and duty cycle is not up to the task.

If the load never varies powering a string of LEDs, for example - then you can play with the duty cycle to get the voltage you need under those conditions. Other than that, the only thing it`s useful for is charging a capacitor. If you wanted to boost a 1. 5V AAA battery up to 12V or 50V and release it all at once, this circuit can get it done. Use it to shock your cat. So a 555 timer isn`t very useful for a boost converter because there`s no easy way to adjust the duty cycle on-the-fly.

But inexpensive PWM controllers do exist perhaps I`ll try that next. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713