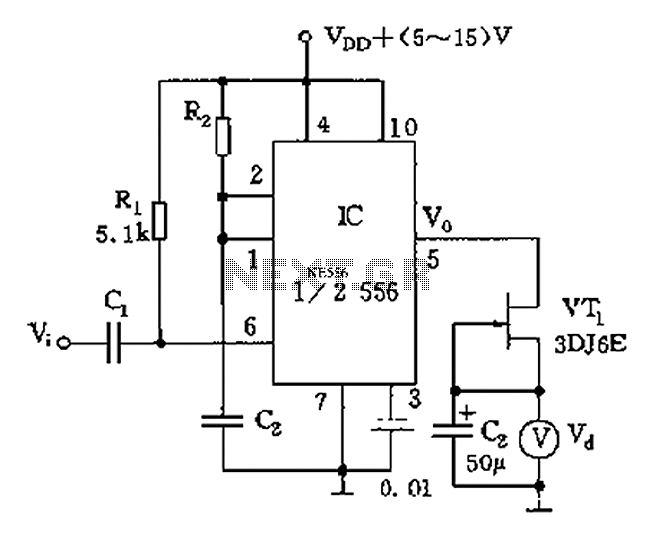

555 tachometer circuit diagram

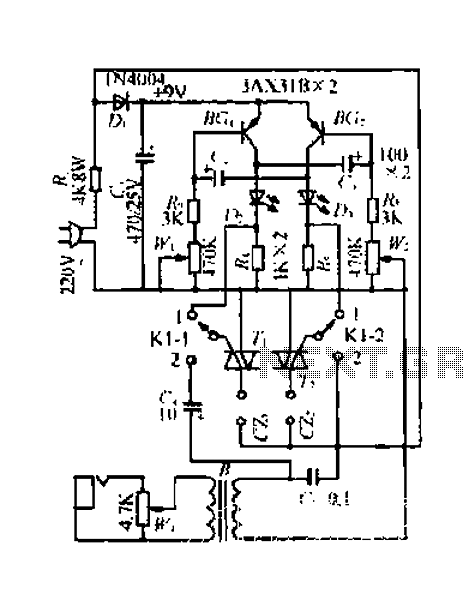

The circuit utilizes switch contacts that are proportional to the speed pulse signal Vi. A differential signal is fed into the trigger side of an integrated circuit (IC), specifically a 555 timer configured in monostable mode (1/2 556), to create a single stabilizing circuit. This circuit generates a pulse of fixed width, defined as td = 1.1R2C2. The number of pulses generated varies with speed, resulting in a one-shot pulse output from a constant current source (VT1). The output is integrated through capacitor C3 to yield a voltage that is proportional to the rotational speed, which can be displayed on a digital meter. This configuration is known as a voltage conversion circuit for speed measurement.

The described circuit operates by converting mechanical rotational speed into an electrical signal that can be easily interpreted. The signal Vi, representing the speed pulse, is first processed through a differential amplifier stage, which enhances the signal quality before it reaches the trigger input of the 555 timer. The timer is set up in a monostable configuration, meaning it will output a single pulse in response to each trigger event.

The pulse width generated by the timer is determined by the resistors and capacitor in the circuit, specifically through the formula td = 1.1R2C2, where R2 is the resistance connected to the discharge pin of the timer and C2 is the timing capacitor. This pulse width remains constant regardless of the input frequency, allowing for accurate timing control.

As the rotational speed increases, the frequency of the input speed pulse Vi also increases, resulting in a greater number of output pulses from the timer. These output pulses are then transformed into a voltage signal using a constant current source (VT1), which ensures that the integration process through capacitor C3 produces a smooth and proportional voltage output. This output voltage is directly related to the rotational speed of the mechanical system being measured.

The final voltage output can be connected to a digital readout meter, providing a clear and precise display of the speed. This circuit is particularly useful in applications where speed monitoring is critical, such as in automotive systems, industrial machinery, or any rotating equipment where accurate speed measurement is essential. The design emphasizes stability and reliability, making it a valuable tool in electronic speed measurement systems. As shown from the switch contacts, proportional to the speed pulse signal Vi, after the differential is added to IC (1/2 556) trigger side to make the single stabilizing circui t generates a pulse of fixed width, td 1.1R2C2, different speed has its proportional number of pulses, one-shot pulse output by the constant current source VT1 and C3 integral to obtain a voltage proportional to the rotational speed, it can speed digital readout on the meter. This circuit is also referred to as the rate of voltage conversion circuit.

The described circuit operates by converting mechanical rotational speed into an electrical signal that can be easily interpreted. The signal Vi, representing the speed pulse, is first processed through a differential amplifier stage, which enhances the signal quality before it reaches the trigger input of the 555 timer. The timer is set up in a monostable configuration, meaning it will output a single pulse in response to each trigger event.

The pulse width generated by the timer is determined by the resistors and capacitor in the circuit, specifically through the formula td = 1.1R2C2, where R2 is the resistance connected to the discharge pin of the timer and C2 is the timing capacitor. This pulse width remains constant regardless of the input frequency, allowing for accurate timing control.

As the rotational speed increases, the frequency of the input speed pulse Vi also increases, resulting in a greater number of output pulses from the timer. These output pulses are then transformed into a voltage signal using a constant current source (VT1), which ensures that the integration process through capacitor C3 produces a smooth and proportional voltage output. This output voltage is directly related to the rotational speed of the mechanical system being measured.

The final voltage output can be connected to a digital readout meter, providing a clear and precise display of the speed. This circuit is particularly useful in applications where speed monitoring is critical, such as in automotive systems, industrial machinery, or any rotating equipment where accurate speed measurement is essential. The design emphasizes stability and reliability, making it a valuable tool in electronic speed measurement systems. As shown from the switch contacts, proportional to the speed pulse signal Vi, after the differential is added to IC (1/2 556) trigger side to make the single stabilizing circui t generates a pulse of fixed width, td 1.1R2C2, different speed has its proportional number of pulses, one-shot pulse output by the constant current source VT1 and C3 integral to obtain a voltage proportional to the rotational speed, it can speed digital readout on the meter. This circuit is also referred to as the rate of voltage conversion circuit.