After the restructuring of AC and DC arc welding machine circuit

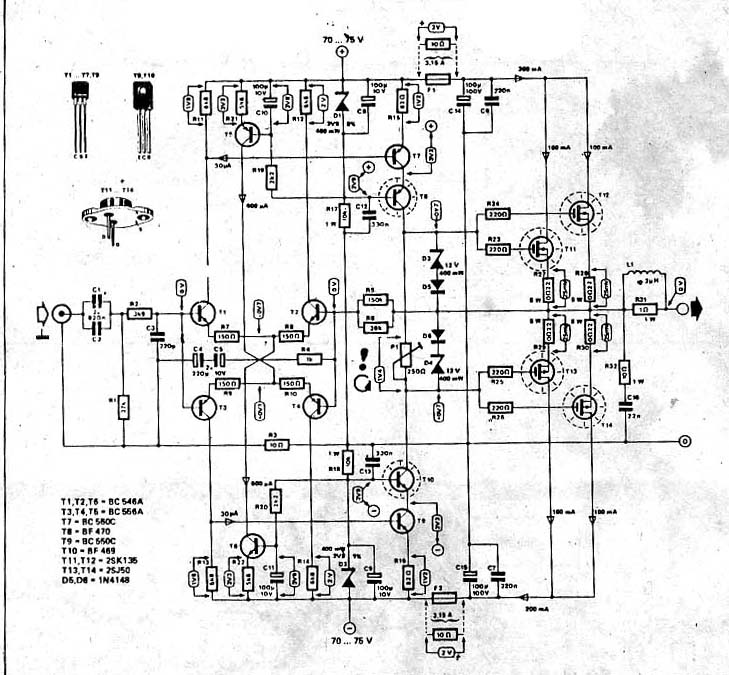

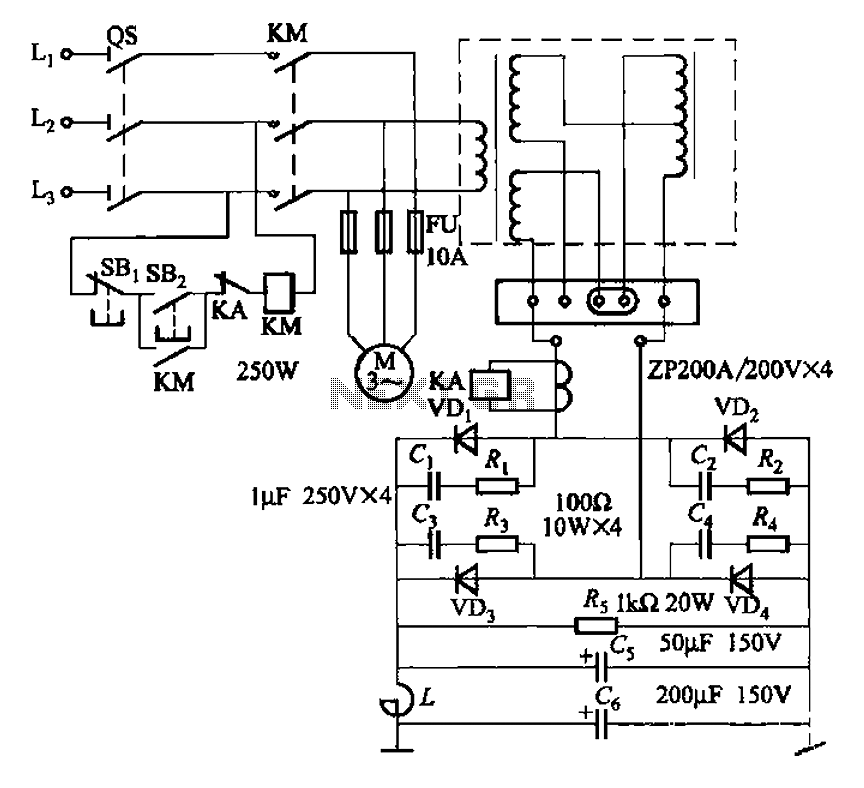

After restructuring the AC and DC arc welding machine circuit on the BX series AC arc welder by installing a rectifier device, it can be converted into an AC and DC arc welding machine. This restructuring results in a machine that produces minimal spatter, uniform welds, and improved speed. It is important to note that for both AC and DC welding rods, the general configuration is positive ground with the negative pole connected to the gun. However, a DC welding rod requires a negative ground and a positive connection to the torch. The circuit restructuring is illustrated in the accompanying figure, featuring an L-shaped core reactor. Cardboard is used to separate the core and a zigzag-shaped core to prevent reactor core saturation. The core dimensions are as follows: a column spacing of 45 mm, a column height of 120 mm, a sheet width of 45 mm, and a stacked thickness of 80 mm. The reactor consists of 25-40 coil turns, with the conductor cross-section matching that of the welding transformer’s secondary wire.

The BX series arc welder, upon modification, offers versatility by enabling both AC and DC welding capabilities. The installation of a rectifier device is a critical component of this transformation, allowing for the conversion of AC input power into a usable DC output for welding applications. The advantages of this restructuring include enhanced control over the welding process, leading to reduced spatter and improved weld consistency, which are crucial for high-quality welding results.

The reactor design plays a significant role in the performance of the welding machine. The L-shaped core is engineered to optimize magnetic flux and minimize losses, while the use of cardboard as a separator between the core and the zigzag-shaped core is a strategic choice to mitigate saturation effects. This design consideration is essential for maintaining efficiency during operation, particularly under varying load conditions.

The specified core dimensions are tailored to ensure that the reactor can handle the required electrical currents while maintaining structural integrity. The column height and spacing are designed to facilitate effective cooling and prevent overheating during extended use. Additionally, the coil turns are calibrated to match the electrical characteristics of the welding transformer, ensuring compatibility and performance reliability.

In summary, the restructuring of the BX series AC arc welder into a dual-capability machine enhances its functionality and efficiency, making it suitable for a wider range of welding tasks while maintaining high-quality output. Proper attention to the reactor design and core specifications is essential for achieving optimal performance in both AC and DC welding modes.After the restructuring of AC and DC arc welding machine circuit On the BX series AC arc welder install a rectifier device, it can be restructured into AC and DC arc welding ma chine. After the restructuring of the arc welding machine with easy, small spatter, uniform welds, fastness advantages. Note: Use the AC and DC welding rod, generally positive ground, the negative pole gun, but a DC welding rod must be negative ground, positive then torch.

After the restructuring of the circuit shown in Fig. Reactor L-shaped core using, separated by cardboard between the core and a zigzag-shaped core prevent reactor core saturation and. Core size: two column spacing 45mm, column height 120mm, sheet width 45mm, stacked thick 80mm; 25-40 coil turns; the same conductor cross section with welding transformer secondary wire section.

The BX series arc welder, upon modification, offers versatility by enabling both AC and DC welding capabilities. The installation of a rectifier device is a critical component of this transformation, allowing for the conversion of AC input power into a usable DC output for welding applications. The advantages of this restructuring include enhanced control over the welding process, leading to reduced spatter and improved weld consistency, which are crucial for high-quality welding results.

The reactor design plays a significant role in the performance of the welding machine. The L-shaped core is engineered to optimize magnetic flux and minimize losses, while the use of cardboard as a separator between the core and the zigzag-shaped core is a strategic choice to mitigate saturation effects. This design consideration is essential for maintaining efficiency during operation, particularly under varying load conditions.

The specified core dimensions are tailored to ensure that the reactor can handle the required electrical currents while maintaining structural integrity. The column height and spacing are designed to facilitate effective cooling and prevent overheating during extended use. Additionally, the coil turns are calibrated to match the electrical characteristics of the welding transformer, ensuring compatibility and performance reliability.

In summary, the restructuring of the BX series AC arc welder into a dual-capability machine enhances its functionality and efficiency, making it suitable for a wider range of welding tasks while maintaining high-quality output. Proper attention to the reactor design and core specifications is essential for achieving optimal performance in both AC and DC welding modes.After the restructuring of AC and DC arc welding machine circuit On the BX series AC arc welder install a rectifier device, it can be restructured into AC and DC arc welding ma chine. After the restructuring of the arc welding machine with easy, small spatter, uniform welds, fastness advantages. Note: Use the AC and DC welding rod, generally positive ground, the negative pole gun, but a DC welding rod must be negative ground, positive then torch.

After the restructuring of the circuit shown in Fig. Reactor L-shaped core using, separated by cardboard between the core and a zigzag-shaped core prevent reactor core saturation and. Core size: two column spacing 45mm, column height 120mm, sheet width 45mm, stacked thick 80mm; 25-40 coil turns; the same conductor cross section with welding transformer secondary wire section.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713