Balanced Low Noise Microphone Preamp

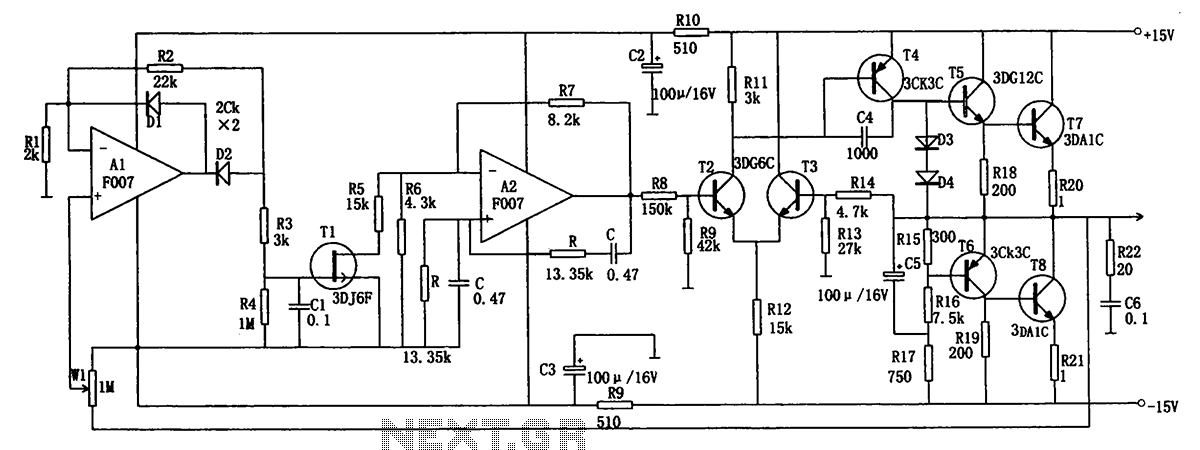

This simple design features very low noise levels, approaching the theoretical minimum, high hum rejection, and variable gain controlled by a single rotary potentiometer. It resembles the circuitry used in many professional-grade mixing desks and can serve as the foundation for a high-performance recording mixer for live applications. The design incorporates differential compound transistor pairs, with a common mode (floating) gain control connecting the emitters of the pair. The compound pairs of 2N4403 and BC549 transistors exhibit greater linearity than any single transistor. The circuit is configured for differential input and output, necessitating a balanced-to-unbalanced buffer to provide an appropriate output for subsequent signal stages in a mixing desk. This function is achieved through a high-performance operational amplifier differential gain stage, which may utilize a TL071 or similar integrated circuit. This stage offers a gain of six or 15 dB, setting the maximum input level at approximately 1.5 volts RMS before clipping, which corresponds to a sound pressure level (SPL) exceeding 150 dB with a typical microphone. The full gain is 1000 times or 60 dB, with distortion remaining low to unmeasurable, as it falls below the noise level at high gains. The common mode rejection ratio (CMRR) exceeds 60 dB, surpassing the effectiveness of conventional microphone cables in terms of hum rejection. The bandwidth extends beyond 100 kHz, and no RF suppression is necessary as it has proven unnecessary in practice. The input impedance, or load on the microphone, is established by two 3.3 k ohm resistors, making it compatible with most microphones having a nominal impedance of 150 to 600 ohms. The input stage is designed for minimal noise, which has led to a non-integrated circuit approach. Although there are specialized integrated circuits available for microphone preamplifiers that incorporate similar designs on a single chip, such as the now-obsolete SSM2017 or its replacement, the INA103, standard components should be readily available, with the exception of the 10 k ohm potentiometer for gain control. This potentiometer should be a reverse log taper, or alternatively, a multi-position switch can be employed with 6 dB gain steps covering the 60 dB range of the circuit. It is essential that the switch is configured as make-before-break. An alternative approach involves using a standard log potentiometer wired "backwards," which functions effectively if labeled "Attenuation" instead of "Gain." In this case, advancing the potentiometer clockwise reduces gain (increases attenuation), with maximum gain occurring when the potentiometer is fully counterclockwise. This issue is not unique to this circuit; all integrated circuit microphone preamps exhibit the same behavior. The +/-15 Volt power supply is also critical; it must be regulated and low noise. When utilizing common voltage regulator ICs, it is advisable to add a post-filter consisting of a 10-ohm resistor and a 470 µF capacitor to eliminate any noise generated by the ICs. Some 7815 ICs may be prone to generating noise, while adjustable voltage regulators (LM317, LM337) tend to be much quieter. A single regulator board can supply power to multiple preamps, with each preamp equipped with its own post-filter circuits. Due to the extensive filtering applied, the P05 (Rev-A) power supply is recommended for this preamp. High-quality components should be utilized, including metal film resistors in the collectors and emitters of the input pairs to minimize noise. When a resistor experiences significant DC voltage in high gain circuits, low-noise types should always be employed. Metal film resistors are among the best options, surpassed only by wire-wound resistors, which may be impractical. Cermet, metal glaze, and older carbon composition types should be avoided, as should bead tantalum capacitors, which are prone to leakage and crackling. The 100 nF capacitor (C6) should be placed as close as possible to the op-amp supply pins, with a ceramic capacitor recommended for optimal bypass performance at high frequencies. The 1000 µF capacitor can be a standard electrolytic rated for 10 or 16 volts. Generally, there are no issues with zero DC.This simple design has very low noise, close to the theoretical minimum, high hum rejection and variable gain with a single rotary pot. It is similar to that used in many professional grade mixing desks and can form the basis of a no compromise recording mixer for live work.

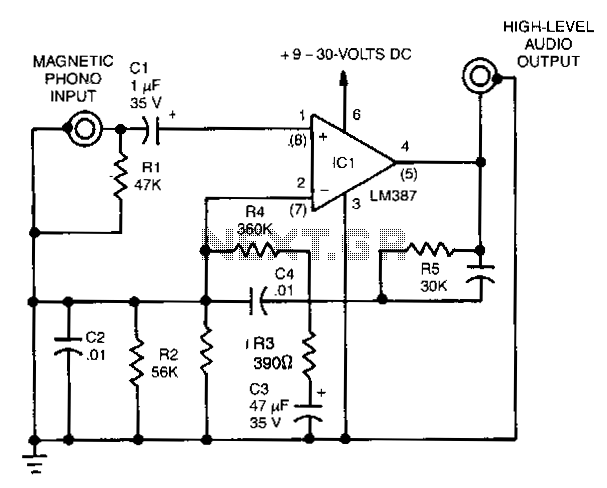

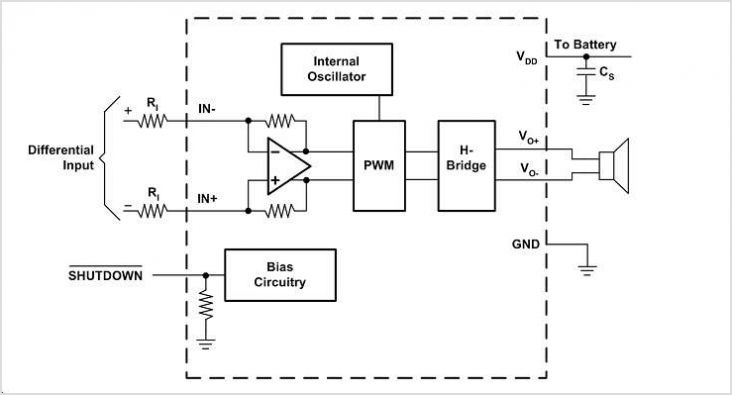

The design consists of differential compound pairs of transistors with a common mode (floating) gain control connecting the emitters of the pair. The compound pairs of 2N4403 and BC549s are far more linear than any single transistor. The circuit is differential in and out and therefore requires a balanced to unbalanced buffer to give suitable output for the next signal stages of a channel in a mixing desk. This is provided by a high performance op-amp differential gain stage, which can be a TL071 or similar IC of your choice.

The stage has a gain of six or 15 dB and that sets the maximum input level at about 1. 5 volts rms before clipping. This equals an SPL of over 150dB with a typical microphone! Full gain is 1000 times or 60dB. Distortion is low to unmeasurable because it is below the noise level at high gains. The CMRR (Common Mode Rejection Ratio) is well over 60 dB and better than any available mic cable as far as hum rejection is concerned. The bandwidth extends beyond 100kHz, and no RF suppression is shown as it has proved unnecessary in practice.

The input impedance or load on the mic is set by the two 3. 3k ohm resistors. This will suit almost any mic with a nominal impedance of 150 to 600 ohms. The input stage is configured for least noise and this has meant a non IC approach. There are some special ICs that can be used for mic pre-amps, they contain a circuit like this one except fabricated on one chip. Examples include the SSM2017 (now obsolete) or the replacement INA103 or similar. Components should all be readily available except for the 10 k ohm pot for the gain control. This needs to be a reverse log taper - or else use a multi-position switch with 6 dB gain steps covering the 60 dB range of the circuit.

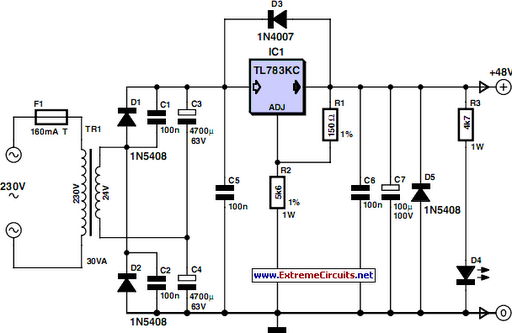

Make sure it is make before break. Editor`s Note - Alternatively, a standard log pot can be used, but wired "backwards". This will work fine if it is labelled "Attenuation" instead of "Gain". As the pot is advanced clockwise, the gain is reduced (attenuation is increased). Maximum gain will therefore be applied when the pot is fully anti-clockwise. Note that this is not a problem that is specific to this circuit - all the IC mic preamps have exactly the same problem. The +/-15 Volt power supply is important too, it must be regulated and low noise. If the usual voltage regulator ICs are used I recommend fitting a post filter consisting of a 10 ohm resistor and a 470 uF capacitor to remove any noise generated in the ICs (as shown in Figure 1).

Some 7815 ICs could be sold as noise generators, the adjustable voltage ones (LM317, LM337) are very much quieter. A single regulator board may be used to power multiple preamps, with each preamp having its own post filter circuits.

Because of the extensive filtering applied, the P05 (Rev-A) power supply is recommended for this preamp. Good quality components should be used with metal film resistors in the collectors and emitters of the input pairs for least noise.

Where a resistor has significant DC voltage imposed on it in high gain circuits always use low noise types. Metal film resistors are about the best only bettered by wire wound which is a bit impractical. Avoid cermet, metal glaze, and very old carbon composition types. Also avoid bead tantalum capacitors, as they go leaky and crackle. They are just about the most fragile electronic components made. The 100nF capacitor (C6) should be mounted as close as possible to the opamp supply pins - a ceramic cap is recommended for best bypass performance at high frequencies.

The 1000uF capacitor can be a normal electrolytic of 10 or 16 volts rating. There is usually no problem with zero DC 🔗 External reference

The design consists of differential compound pairs of transistors with a common mode (floating) gain control connecting the emitters of the pair. The compound pairs of 2N4403 and BC549s are far more linear than any single transistor. The circuit is differential in and out and therefore requires a balanced to unbalanced buffer to give suitable output for the next signal stages of a channel in a mixing desk. This is provided by a high performance op-amp differential gain stage, which can be a TL071 or similar IC of your choice.

The stage has a gain of six or 15 dB and that sets the maximum input level at about 1. 5 volts rms before clipping. This equals an SPL of over 150dB with a typical microphone! Full gain is 1000 times or 60dB. Distortion is low to unmeasurable because it is below the noise level at high gains. The CMRR (Common Mode Rejection Ratio) is well over 60 dB and better than any available mic cable as far as hum rejection is concerned. The bandwidth extends beyond 100kHz, and no RF suppression is shown as it has proved unnecessary in practice.

The input impedance or load on the mic is set by the two 3. 3k ohm resistors. This will suit almost any mic with a nominal impedance of 150 to 600 ohms. The input stage is configured for least noise and this has meant a non IC approach. There are some special ICs that can be used for mic pre-amps, they contain a circuit like this one except fabricated on one chip. Examples include the SSM2017 (now obsolete) or the replacement INA103 or similar. Components should all be readily available except for the 10 k ohm pot for the gain control. This needs to be a reverse log taper - or else use a multi-position switch with 6 dB gain steps covering the 60 dB range of the circuit.

Make sure it is make before break. Editor`s Note - Alternatively, a standard log pot can be used, but wired "backwards". This will work fine if it is labelled "Attenuation" instead of "Gain". As the pot is advanced clockwise, the gain is reduced (attenuation is increased). Maximum gain will therefore be applied when the pot is fully anti-clockwise. Note that this is not a problem that is specific to this circuit - all the IC mic preamps have exactly the same problem. The +/-15 Volt power supply is important too, it must be regulated and low noise. If the usual voltage regulator ICs are used I recommend fitting a post filter consisting of a 10 ohm resistor and a 470 uF capacitor to remove any noise generated in the ICs (as shown in Figure 1).

Some 7815 ICs could be sold as noise generators, the adjustable voltage ones (LM317, LM337) are very much quieter. A single regulator board may be used to power multiple preamps, with each preamp having its own post filter circuits.

Because of the extensive filtering applied, the P05 (Rev-A) power supply is recommended for this preamp. Good quality components should be used with metal film resistors in the collectors and emitters of the input pairs for least noise.

Where a resistor has significant DC voltage imposed on it in high gain circuits always use low noise types. Metal film resistors are about the best only bettered by wire wound which is a bit impractical. Avoid cermet, metal glaze, and very old carbon composition types. Also avoid bead tantalum capacitors, as they go leaky and crackle. They are just about the most fragile electronic components made. The 100nF capacitor (C6) should be mounted as close as possible to the opamp supply pins - a ceramic cap is recommended for best bypass performance at high frequencies.

The 1000uF capacitor can be a normal electrolytic of 10 or 16 volts rating. There is usually no problem with zero DC 🔗 External reference