Lead-Acid Battery Charger Monitor

According to the manufacturer's data sheets, a 12V rechargeable lead-acid battery should be operated within a voltage range of 10.1V to 13.8V. Charging the battery above 13.8V can lead to potential damage.

Lead-acid batteries are commonly used in various applications due to their reliability and cost-effectiveness. Proper voltage management is critical to ensure the longevity and efficiency of these batteries. The specified operating range of 10.1V to 13.8V indicates the safe limits for both discharge and charge cycles.

When the battery voltage drops below 10.1V, it may enter a deep discharge state, which can cause irreversible damage to the cells. On the other hand, exceeding the upper limit of 13.8V during charging can lead to overcharging, which may result in excessive gassing, overheating, and ultimately, a reduction in battery life.

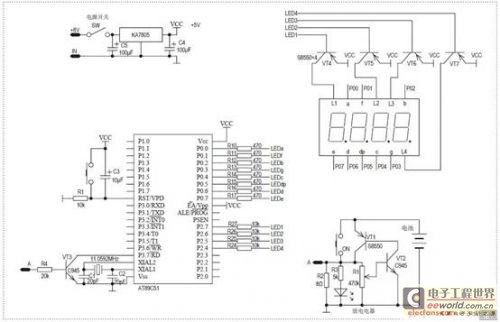

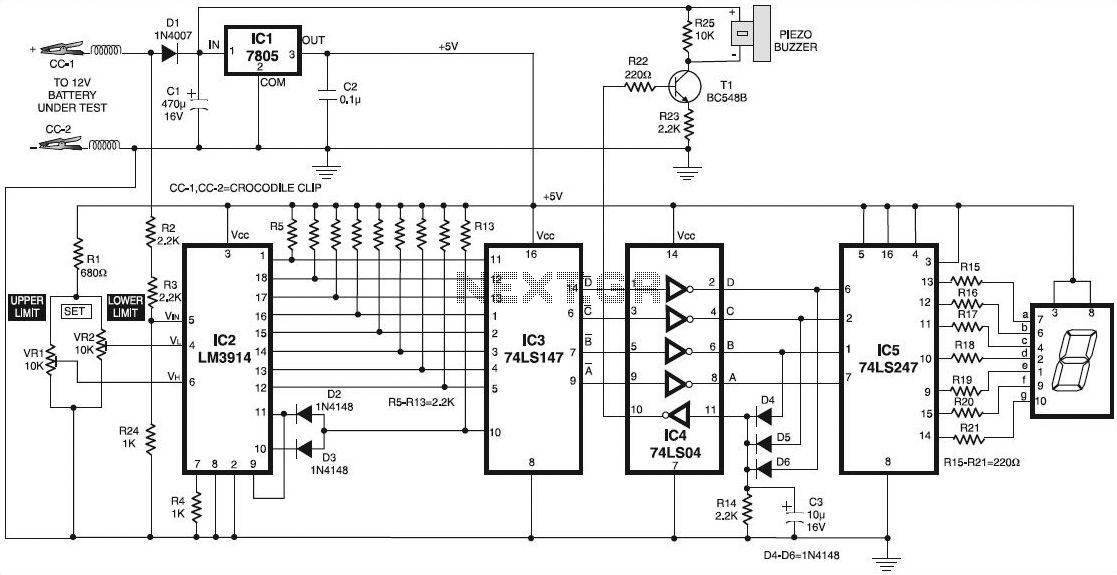

To maintain the battery within these voltage limits, a voltage regulator or a battery management system (BMS) is often employed. A BMS monitors the battery's voltage, current, and temperature, ensuring that the charging process is controlled and that the battery operates within the specified parameters. The design may include a microcontroller that regulates the charging voltage and current, along with protective circuitry to prevent overvoltage and undervoltage conditions.

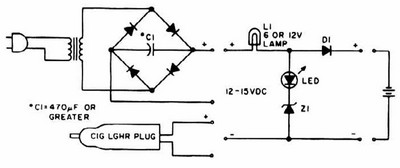

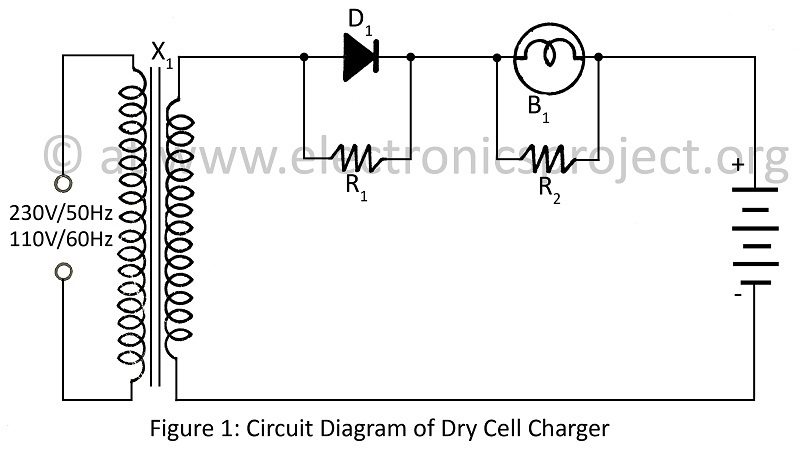

Additionally, the schematic may feature a charging circuit that incorporates a transformer, rectifier, and filtering components to convert AC voltage to a stable DC output suitable for charging the battery. The use of fuses or circuit breakers is also recommended to protect against short circuits and overload conditions.

In summary, maintaining a 12V lead-acid battery within the voltage range of 10.1V to 13.8V is essential for optimal performance and longevity. Implementing a robust charging and management circuit will ensure that the battery operates efficiently without exceeding its safe operational limits.As per manufacturer s data sheets, a 12V rechargeable lead-acid battery should be operated within 10.1V and 13.8V. When the battery charges higher than 13 🔗 External reference

Lead-acid batteries are commonly used in various applications due to their reliability and cost-effectiveness. Proper voltage management is critical to ensure the longevity and efficiency of these batteries. The specified operating range of 10.1V to 13.8V indicates the safe limits for both discharge and charge cycles.

When the battery voltage drops below 10.1V, it may enter a deep discharge state, which can cause irreversible damage to the cells. On the other hand, exceeding the upper limit of 13.8V during charging can lead to overcharging, which may result in excessive gassing, overheating, and ultimately, a reduction in battery life.

To maintain the battery within these voltage limits, a voltage regulator or a battery management system (BMS) is often employed. A BMS monitors the battery's voltage, current, and temperature, ensuring that the charging process is controlled and that the battery operates within the specified parameters. The design may include a microcontroller that regulates the charging voltage and current, along with protective circuitry to prevent overvoltage and undervoltage conditions.

Additionally, the schematic may feature a charging circuit that incorporates a transformer, rectifier, and filtering components to convert AC voltage to a stable DC output suitable for charging the battery. The use of fuses or circuit breakers is also recommended to protect against short circuits and overload conditions.

In summary, maintaining a 12V lead-acid battery within the voltage range of 10.1V to 13.8V is essential for optimal performance and longevity. Implementing a robust charging and management circuit will ensure that the battery operates efficiently without exceeding its safe operational limits.As per manufacturer s data sheets, a 12V rechargeable lead-acid battery should be operated within 10.1V and 13.8V. When the battery charges higher than 13 🔗 External reference