Dry Cell Charger

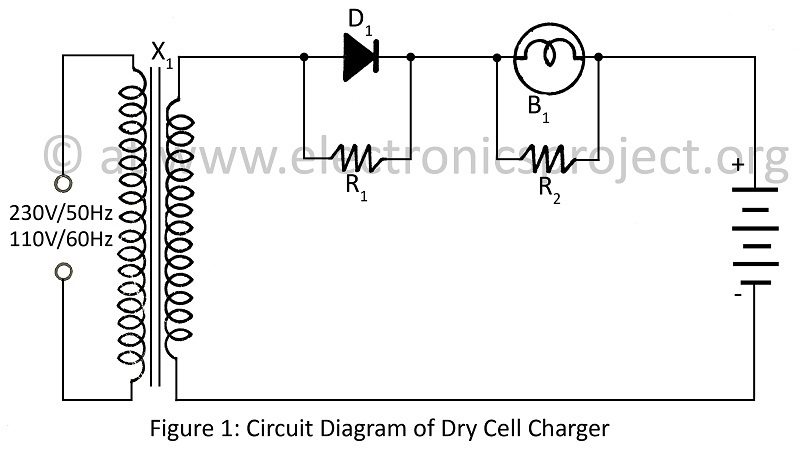

A dry cell charger designed to recharge dry cells 6 to 8 times using a minimal number of components, based on the principle of Periodic Current Reversal (PCR). The circuit diagram is applicable to various projects.

The dry cell charger operates on the principle of Periodic Current Reversal (PCR), which enhances the efficiency of the charging process by periodically reversing the current direction. This method helps in reducing the buildup of gas bubbles on the electrode surfaces, which can hinder the charging process and prolong the lifespan of the dry cell.

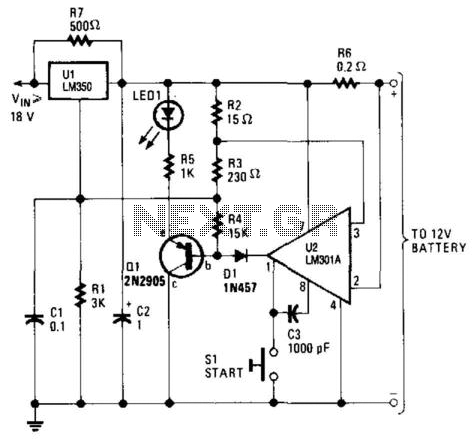

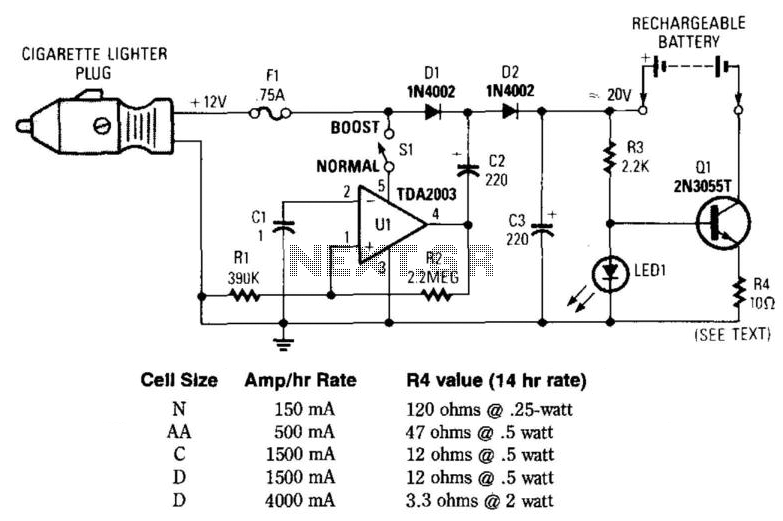

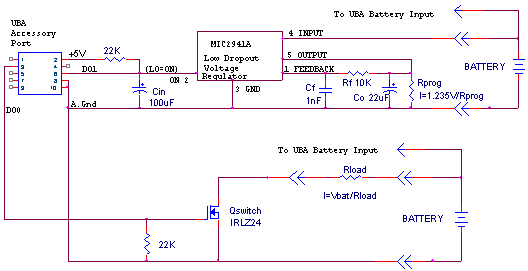

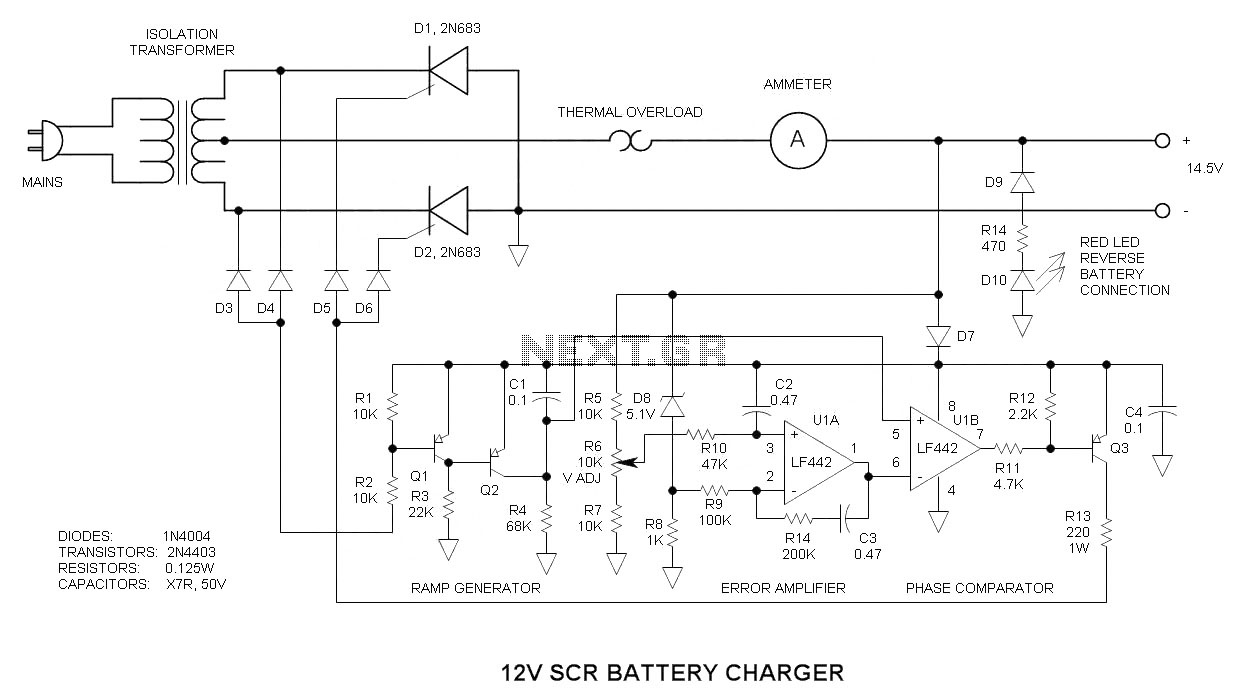

The circuit typically consists of a few key components: a power supply, a switching mechanism, and a control circuit. The power supply provides the necessary voltage and current for charging the dry cell. The switching mechanism, often implemented using transistors or relays, alternates the current flow direction at predetermined intervals. The control circuit may include a timer or microcontroller to manage the switching frequency and duration, ensuring optimal charging conditions.

The schematic diagram for this charger would include the power supply connected to the input of the switching mechanism. The output of the switching mechanism would be linked to the terminals of the dry cell. Additional components such as resistors, capacitors, and diodes may be included to stabilize the circuit and protect against voltage spikes.

This design is particularly advantageous for applications where a reliable and efficient charging method is required without the complexity of larger, more intricate circuits. The use of fewer components not only simplifies the construction but also reduces the overall cost, making it an attractive solution for various DIY projects and practical applications in battery management.Dry Cell Charger utilizing very few component for recharging dry cell 6 to 8 time using principle PCR (Periodic Current Reversal) circuit diagram of various project. 🔗 External reference

The dry cell charger operates on the principle of Periodic Current Reversal (PCR), which enhances the efficiency of the charging process by periodically reversing the current direction. This method helps in reducing the buildup of gas bubbles on the electrode surfaces, which can hinder the charging process and prolong the lifespan of the dry cell.

The circuit typically consists of a few key components: a power supply, a switching mechanism, and a control circuit. The power supply provides the necessary voltage and current for charging the dry cell. The switching mechanism, often implemented using transistors or relays, alternates the current flow direction at predetermined intervals. The control circuit may include a timer or microcontroller to manage the switching frequency and duration, ensuring optimal charging conditions.

The schematic diagram for this charger would include the power supply connected to the input of the switching mechanism. The output of the switching mechanism would be linked to the terminals of the dry cell. Additional components such as resistors, capacitors, and diodes may be included to stabilize the circuit and protect against voltage spikes.

This design is particularly advantageous for applications where a reliable and efficient charging method is required without the complexity of larger, more intricate circuits. The use of fewer components not only simplifies the construction but also reduces the overall cost, making it an attractive solution for various DIY projects and practical applications in battery management.Dry Cell Charger utilizing very few component for recharging dry cell 6 to 8 time using principle PCR (Periodic Current Reversal) circuit diagram of various project. 🔗 External reference