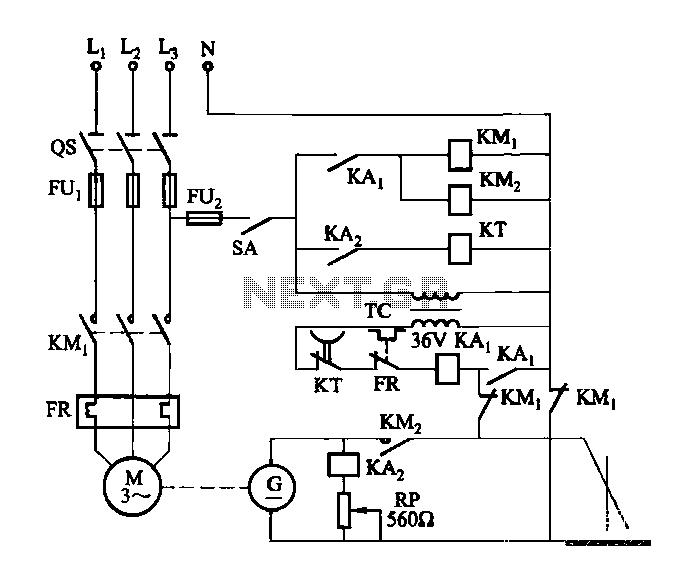

DC arc welding machine no-load power path from 2

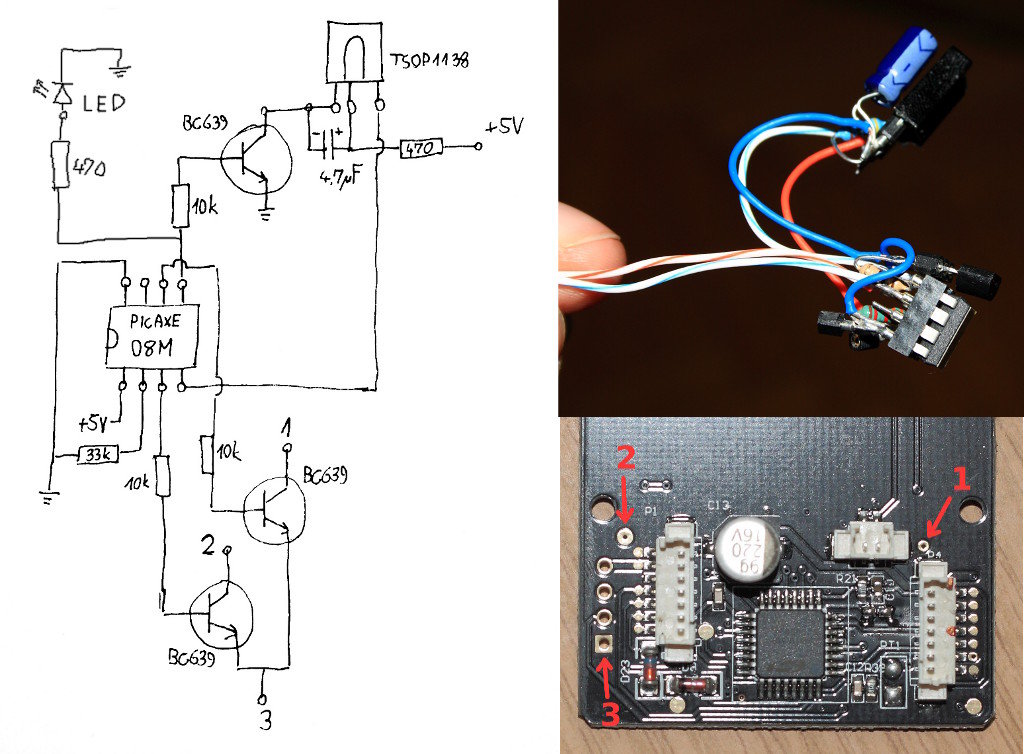

The DC arc welding machine is connected to the secondary load path of the power circuit as illustrated in the figure. This circuit is designed for use during extended downtime, approximately lasting a few minutes, and is not suitable for frequent fan starts. The no-load power path for the DC arc welding machine is derived from the second load path.

The DC arc welding machine operates by converting electrical energy into thermal energy through the process of arc generation between the electrode and the workpiece. The power circuit configuration is critical for ensuring that the machine functions efficiently during its intended use. The secondary load path allows the machine to draw power under specific conditions, particularly during periods of inactivity, which aids in maintaining the machine's operational readiness without the need for continuous power supply.

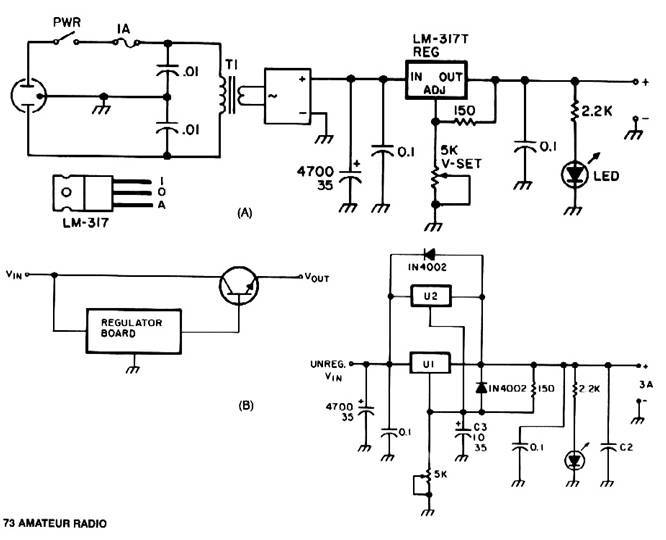

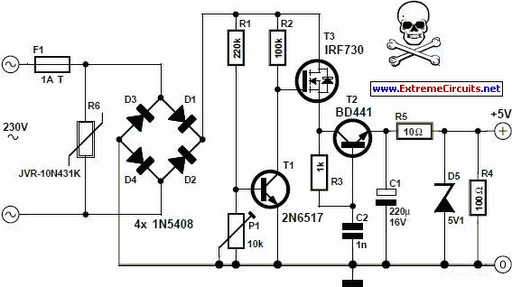

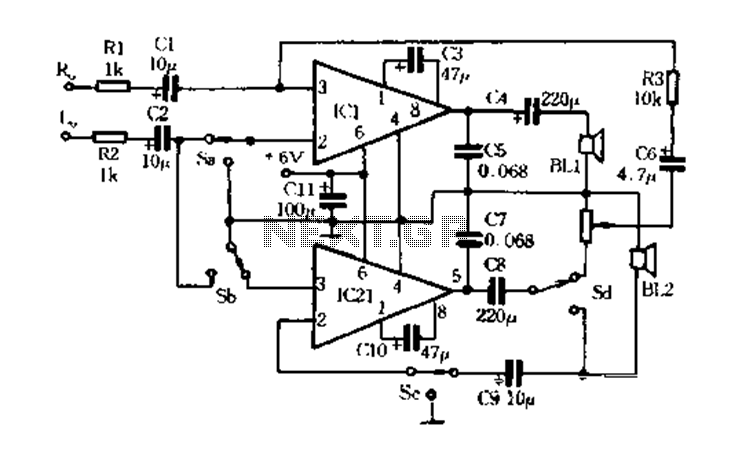

The power circuit should include components such as a transformer to step down the voltage to a suitable level for the welding operation, rectifiers to convert AC to DC, and various protection devices like fuses and circuit breakers to safeguard against overload conditions. Additionally, the inclusion of capacitors may be necessary to smooth out voltage fluctuations and provide stable operation.

The design of the no-load power path is particularly important, as it ensures that the welding machine can remain powered without engaging the welding process, thus preventing wear on the machine's components. This path must be optimized to minimize energy loss while ensuring that the machine is ready for immediate operation when required.

Overall, the circuit configuration for the DC arc welding machine must be carefully designed to accommodate the specific operational requirements, ensuring reliability and efficiency during both active and inactive periods.DC arc welding machine from the second load path of the power circuit shown in Fig. The circuit is only available for a longer downtime (approximately minutes) occasions, does not apply to frequent fan starts. DC arc welding machine no-load power path from 2

The DC arc welding machine operates by converting electrical energy into thermal energy through the process of arc generation between the electrode and the workpiece. The power circuit configuration is critical for ensuring that the machine functions efficiently during its intended use. The secondary load path allows the machine to draw power under specific conditions, particularly during periods of inactivity, which aids in maintaining the machine's operational readiness without the need for continuous power supply.

The power circuit should include components such as a transformer to step down the voltage to a suitable level for the welding operation, rectifiers to convert AC to DC, and various protection devices like fuses and circuit breakers to safeguard against overload conditions. Additionally, the inclusion of capacitors may be necessary to smooth out voltage fluctuations and provide stable operation.

The design of the no-load power path is particularly important, as it ensures that the welding machine can remain powered without engaging the welding process, thus preventing wear on the machine's components. This path must be optimized to minimize energy loss while ensuring that the machine is ready for immediate operation when required.

Overall, the circuit configuration for the DC arc welding machine must be carefully designed to accommodate the specific operational requirements, ensuring reliability and efficiency during both active and inactive periods.DC arc welding machine from the second load path of the power circuit shown in Fig. The circuit is only available for a longer downtime (approximately minutes) occasions, does not apply to frequent fan starts. DC arc welding machine no-load power path from 2

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713