Digital Electronics Education

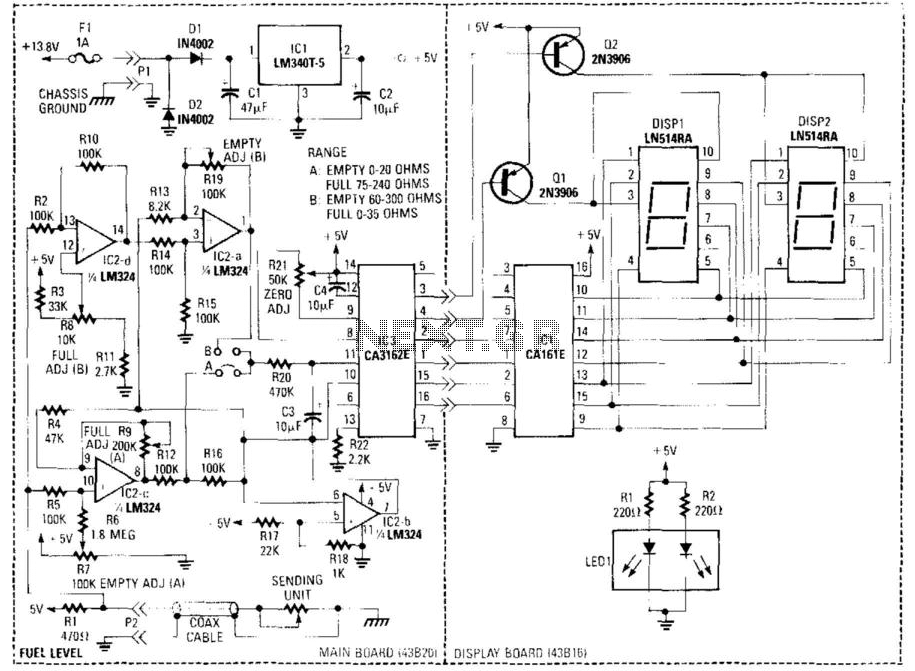

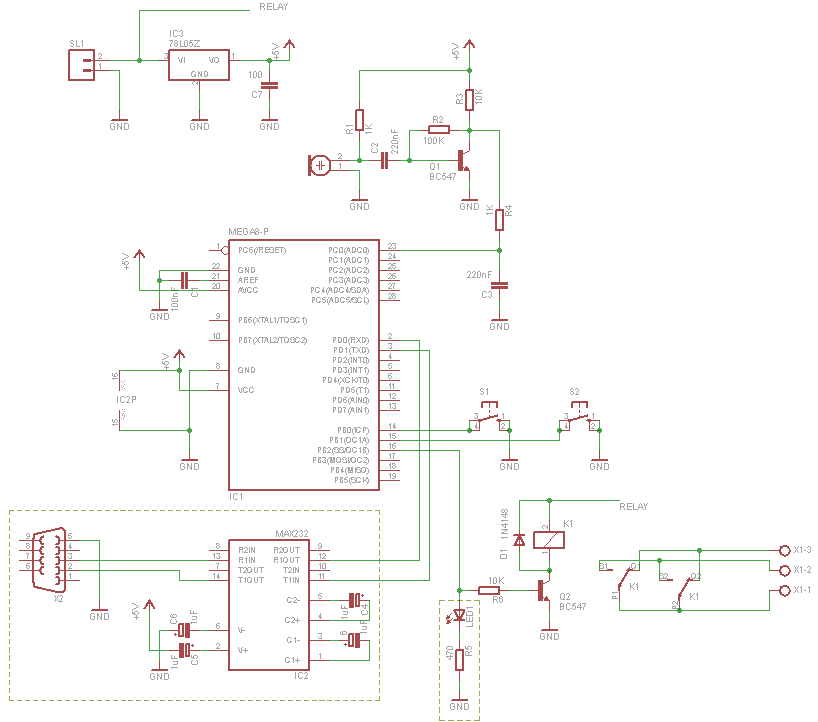

The goal of Advanced Digital Electronics courses is to connect basic logic gates (combinational circuits) with technical subjects related to binary counter topologies (both Asynchronous and Synchronous), shift registers, memory, and Digital Signal Processors (DSP), which are categorized as sequential devices. Fundamental design tools such as Boolean Algebra, Karnaugh Maps (K-Maps), Truth Tables, and Finite State Machines (FSM) are utilized to demonstrate how combinational circuits contribute to the development of these sequential digital devices. To synthesize the application of these digital building blocks in industrial equipment and consumer products, New Product Development (NPD) practices can be effectively integrated into the curriculum. This paper will explore how NPD can be introduced to advanced second-year Computer and Electronics Engineering Technology (CEET) students through a Digital Design Project. The product creation process involves conceptualizing an idea and progressing to the development of the finished product. Research Design Experts indicate that professional technologists face numerous design challenges in the technical environment. Technologies have evolved rapidly, and contemporary engineering practices exhibit a high degree of integration among previously distinct technical domains. Consequently, the design of many products necessitates skills and knowledge that cannot be acquired by a single individual or even a small group. Engineering design has transformed into a collaborative activity. The New Product Development Process functions as a dynamic design framework that incorporates a multidisciplinary team approach, leveraging the expertise of engineers, technicians, and technologists. Figure 1 illustrates a whiteboard approach to product creation. The first gate of NPD involves defining the problem that this multidisciplinary team will address through product development. To exemplify this first gate, advanced CEET students are introduced to Multisim software as a virtual analysis tool for validating potential solutions to a given lab project problem. For instance, a 4-Bit Digital Controller was required to provide a visual indication of when four-bit serial shift register cells are filled with binary 1s (e.g., 1111). To devise a solution for this lab project challenge, System Block Diagrams were introduced as a Problem Definition tool for CEET students. A System Block Diagram is primarily a graphical design tool where blocks represent subcircuits, such as a 2-Input NAND logic gate connected to another block identified as an LED circuit. An arrow symbol is used to illustrate the interconnecting relationship between the two blocks. This basic logic gate circuit System Block Diagram is depicted in Figure 2. By graphically defining the subcircuits that comprise the final product of a 4-Bit Digital Controller, the fundamental principles of digital flip-flop operation are reinforced during the Design and Problem Definition phase of the NPD process. Before constructing the virtual controller using Multisim, each student was required to create a System Block Diagram for the instructor's approval. To foster a collaborative design environment in the lab, students were encouraged to work in teams or seek advice from peers if they opted for individual lab participation. Once the 4-Bit Digital Controller was validated within Multisim for correct circuit functionality and approved by the instructor, students progressed to Gate 2 of the NPD process, which involves building a physical working prototype of the digital controller. The solderless breadboard is a commonly used prototyping tool by electrical engineers, electronic technicians, and technologists to validate the feasibility of a concept. To illustrate, an advanced Embedded Controls development product using Powerline Technology for operating a ceiling fan with a remote hardwired wall control was discussed, for which the lead product developer was involved. The communication protocol that enables the wall control to communicate with the ceiling fan's receiver, AC motor, and light bulb driver circuits was validated using a solderless breadboard. Figure 3 presents the low-fidelity prototype ceiling fan embedded Powerline controller built on a solderless breadboard. The emphasis on circuit simulation, physical prototyping, and testing was the central theme of the advanced Digital Electronics course during the 10-week quarter session, alongside the introduction of the two discussed Product Development Gates, Design and Build. Another critical aspect of NPD is the ability to assess the feasibility of a product concept through a functional prototype. In most consumer product companies, marketing is responsible for establishing Design Guidelines concerning key attributes of the target device. The Feasibility document captures these attributes, along with projected volumes and piece costs for the specific product. In developing Human Machine Interfaces (HID) for consumer appliances such as cell phones, coffee makers, and tablets, sensing devices and controls operate in the background, retrieving data and processing the corresponding bits and bytes based on HID interactions with users. The initial step in validating a consumer product HID is to construct a Proof of Concept (PoC) device. For electronic controls, the solderless breadboard, along with circuit elements from other devices, aids the Electronics Engineering Technician in building the PoC efficiently. The circuit element method involves using specific components like LEDs, motors, and switches, and employing jumper wires to connect them to the designer's core electronic circuit or subsystem. This technique accelerates the product development process and assists in demonstrating a concept's feasibility. Consequently, the solderless breadboard and circuit building were emphasized weekly to students, complemented by actual product build examples (Figures 3 and 4). As illustrated in Figures 3 and 4, the tools applied in an academic setting are effectively utilized in industry by engineers, technicians, and technologists. The advanced Digital Electronics students were highly motivated by these real-world examples and product development techniques, which were showcased in their Final Design Projects for the course. To exemplify how the skills acquired in an advanced Digital Electronics course can be applied in an entrepreneurial venture, a small NPD Logic Probe Kit development project, created for Electronics Technology Education and the hobbyist market, was discussed. Figure 5 presents the prototype Logic Probe Kit developed for this purpose. This practical NPD project illustrates how a solderless breadboard can be utilized in various projects.The objective of Advanced Digital Electronics courses is to bridge basic logic gates (combinational circuits) with technical topics related to binary counter topologies (Asynchronous & Synchronous), shift registers, memory, and DSP (Digital Signal Processors) which fall under the sequential devices umbrella. The fundamental design tools of using B oolean Algebra, K-Maps, Truth Tables, and Finite State Machines (FSM) aid in illustrating how combinational circuits can assist in the construction of such sequential digital devices mentioned. To provide a synthesis of how these digital building blocks are used in the creation of industrial equipment and consumer products, New Product Development (NPD) practices can be integrated quite seamlessly into the curriculum.

This paper will discuss how NPD can be introduced to advanced 2year Computer and Electronics Engineering Technology (CEET) Students via a Digital Design Project. The product creation process consists of fundamentally conceiving an idea for cultivation and eventually the development of the finished good.

According to Research Design Experts, the professional technologist is confronted by many design challenges in the technical environment. [1] Technologies have rapidly, and current engineering practice features a high level of integration of technologies that were once regarded as separate technical domains.

This means that the designs of many products require skills and knowledge that cannot be encompassed by a single individual, or even a small group of individuals. Engineering design has become a team activity. The New Product Development Process is a living design machine that embodies a multidisciplinary team approach using the skill-sets of engineers, technicians, and technologists.

Figure 1 illustrates a [2] Whiteboard approach of product creation. The first [3] Gate of NPD is defining the problem for which this multidisciplinary team will solve through product creation. To illustrate this first Gate event, advanced CEET students are introduced to using Multisim software as virtual analysis tool for validating a possible solution to a given Lab Project problem.

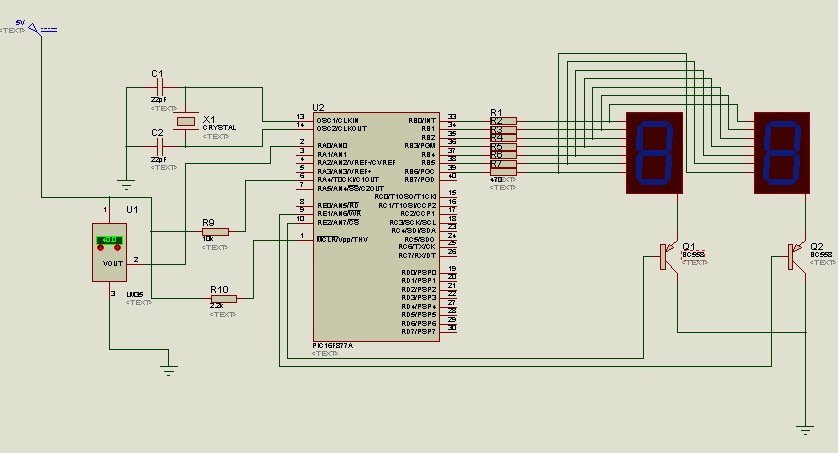

For example, a 4Bit Digital Controller was needed to provide a visual status of when a four bit serial shift register cells are filled with binary 1`s (e. g. 1111). To develop a solution to this Lab Project challenge, System Block Diagrams were introduced as a Problem Definition tool to CEET Students.

A System Block Diagram is primarily a graphical design tool whereby a block represents a subcircuit such as a 2 Input NAND logic gate attached to another block identified as a LED circuit. To show the interconnecting relationship between the 2 blocks an arrow symbol is used. This basic logic gate circuit System Block Diagram is illustrated in Figure 2. By graphically defining the subcircuits that makeup the final product of a 4Bit Digital Controller, basic principles of how digital flip-flops operate are reinforced during the Design and Problem Definition phase of the NPD process.

Prior to building the virtual controller using Multisim, each student had to create a System Block diagram for an Instructor`s Signature (the Author) Sign Off. To create a design environment within the lab, students were encouraged to work in teams or to seek advice from their peers if individual lab participation was desired.

After the 4Bit Digital Controller was validated within Multisim for correct circuit functionality and signed off by the Instructor, the students then proceeded to Gate 2 event. This next phase of the NPD process is to build a physical working prototype of the digital controller.

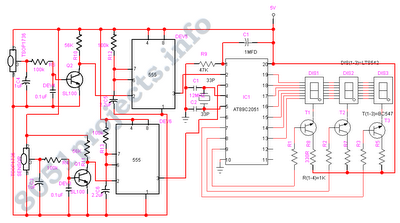

The solderless breadboard is one of the commonly used prototyping tools employed by Electrical Engineers, Electronic Technicians, and Technologists to validate a concept`s feasibility. To illustrate, the author discussed an advanced Embedded Controls development product using Powerline Technology for operating a ceiling fan with a remote hardwired wall control for which he was the Lead Product Developer.

The communications protocol for allowing the wall control to talk with the ceiling fan`s receiver, the AC motor, and light bulb driver circuits were validated using a solderless breadboard. Figure 3 shows the low fidelity prototype ceiling fan embedded Powerline controller built on a solderless breadboard.

The emphasis of circuit simulation and physical prototyping and testing was the main theme of the advanced Digital Electronics course for the 10week quarter session along with the introduction of the 2 discussed Product Development Gates of Design and Build . Another critical area in NPD is the ability to check the feasibility of a product concept with the aid of a functional prototype.

Marketing is responsible in most consumer products companies for establishing Design Guidelines as it relates to key attributes of the target device. The Feasibility document captures these attributes along with projected volumes and piece cost for the specific product.

In developing Human Machine Interfaces (HID) for consumer appliances like cell-phones, coffee makers, and pc tablets, sensing devices & controls are in the background retrieving data and processing the equivalent bits and bytes based on the HID interactions with the customer. The first step in validating a consumer product HID is to build a Proof of Concept (PoC) device. For electronic controls, the solderless breadboard along with sneaking circuits from other devices aid the Electronics Engineering Technician in building the PoC easily and expediently.

The sneaking circuit method consists of taking either specific components like LEDs, motors, & switches and using jumper wires attach to them to physically connect to the designer`s core electronic circuit or subsystem. This technique rapidly expedites the product development process as well as assists in proving a concept`s feasibility.

Therefore, the solderless breadboard and circuit building was emphasized weekly to the students along with actual product build examples (Figure 3) and Figure 4. As illustrated in Figures 3 and 4, the tools used in an Academia setting are actually put into Industry practice by engineers, technicians and technologists.

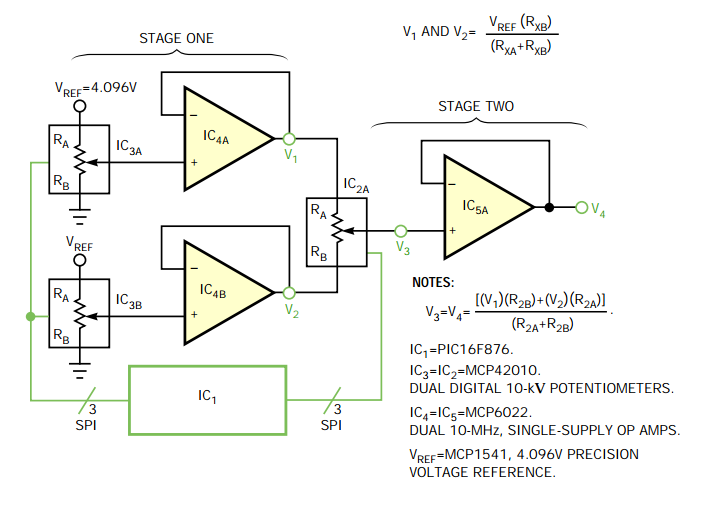

The advanced Digital Electronics students were quite motivated by these real world examples and product development techniques and were demonstrated in their Final Design Projects for the course. And to illustrate how the skills being obtained in an advanced Digital Electronics course can be used in an entrepreneurial venture, a small NPD Logic Probe Kit development project created by the Author for Electronics Technology Education and the Hobbyist market was discussed.

Figure 5 shows the prototype Logic Probe Kit created by the Author. This practical NPD project illustrates how a solderless on oprojects can be found at the website: 🔗 External reference

This paper will discuss how NPD can be introduced to advanced 2year Computer and Electronics Engineering Technology (CEET) Students via a Digital Design Project. The product creation process consists of fundamentally conceiving an idea for cultivation and eventually the development of the finished good.

According to Research Design Experts, the professional technologist is confronted by many design challenges in the technical environment. [1] Technologies have rapidly, and current engineering practice features a high level of integration of technologies that were once regarded as separate technical domains.

This means that the designs of many products require skills and knowledge that cannot be encompassed by a single individual, or even a small group of individuals. Engineering design has become a team activity. The New Product Development Process is a living design machine that embodies a multidisciplinary team approach using the skill-sets of engineers, technicians, and technologists.

Figure 1 illustrates a [2] Whiteboard approach of product creation. The first [3] Gate of NPD is defining the problem for which this multidisciplinary team will solve through product creation. To illustrate this first Gate event, advanced CEET students are introduced to using Multisim software as virtual analysis tool for validating a possible solution to a given Lab Project problem.

For example, a 4Bit Digital Controller was needed to provide a visual status of when a four bit serial shift register cells are filled with binary 1`s (e. g. 1111). To develop a solution to this Lab Project challenge, System Block Diagrams were introduced as a Problem Definition tool to CEET Students.

A System Block Diagram is primarily a graphical design tool whereby a block represents a subcircuit such as a 2 Input NAND logic gate attached to another block identified as a LED circuit. To show the interconnecting relationship between the 2 blocks an arrow symbol is used. This basic logic gate circuit System Block Diagram is illustrated in Figure 2. By graphically defining the subcircuits that makeup the final product of a 4Bit Digital Controller, basic principles of how digital flip-flops operate are reinforced during the Design and Problem Definition phase of the NPD process.

Prior to building the virtual controller using Multisim, each student had to create a System Block diagram for an Instructor`s Signature (the Author) Sign Off. To create a design environment within the lab, students were encouraged to work in teams or to seek advice from their peers if individual lab participation was desired.

After the 4Bit Digital Controller was validated within Multisim for correct circuit functionality and signed off by the Instructor, the students then proceeded to Gate 2 event. This next phase of the NPD process is to build a physical working prototype of the digital controller.

The solderless breadboard is one of the commonly used prototyping tools employed by Electrical Engineers, Electronic Technicians, and Technologists to validate a concept`s feasibility. To illustrate, the author discussed an advanced Embedded Controls development product using Powerline Technology for operating a ceiling fan with a remote hardwired wall control for which he was the Lead Product Developer.

The communications protocol for allowing the wall control to talk with the ceiling fan`s receiver, the AC motor, and light bulb driver circuits were validated using a solderless breadboard. Figure 3 shows the low fidelity prototype ceiling fan embedded Powerline controller built on a solderless breadboard.

The emphasis of circuit simulation and physical prototyping and testing was the main theme of the advanced Digital Electronics course for the 10week quarter session along with the introduction of the 2 discussed Product Development Gates of Design and Build . Another critical area in NPD is the ability to check the feasibility of a product concept with the aid of a functional prototype.

Marketing is responsible in most consumer products companies for establishing Design Guidelines as it relates to key attributes of the target device. The Feasibility document captures these attributes along with projected volumes and piece cost for the specific product.

In developing Human Machine Interfaces (HID) for consumer appliances like cell-phones, coffee makers, and pc tablets, sensing devices & controls are in the background retrieving data and processing the equivalent bits and bytes based on the HID interactions with the customer. The first step in validating a consumer product HID is to build a Proof of Concept (PoC) device. For electronic controls, the solderless breadboard along with sneaking circuits from other devices aid the Electronics Engineering Technician in building the PoC easily and expediently.

The sneaking circuit method consists of taking either specific components like LEDs, motors, & switches and using jumper wires attach to them to physically connect to the designer`s core electronic circuit or subsystem. This technique rapidly expedites the product development process as well as assists in proving a concept`s feasibility.

Therefore, the solderless breadboard and circuit building was emphasized weekly to the students along with actual product build examples (Figure 3) and Figure 4. As illustrated in Figures 3 and 4, the tools used in an Academia setting are actually put into Industry practice by engineers, technicians and technologists.

The advanced Digital Electronics students were quite motivated by these real world examples and product development techniques and were demonstrated in their Final Design Projects for the course. And to illustrate how the skills being obtained in an advanced Digital Electronics course can be used in an entrepreneurial venture, a small NPD Logic Probe Kit development project created by the Author for Electronics Technology Education and the Hobbyist market was discussed.

Figure 5 shows the prototype Logic Probe Kit created by the Author. This practical NPD project illustrates how a solderless on oprojects can be found at the website: 🔗 External reference