Dot matrix LED display

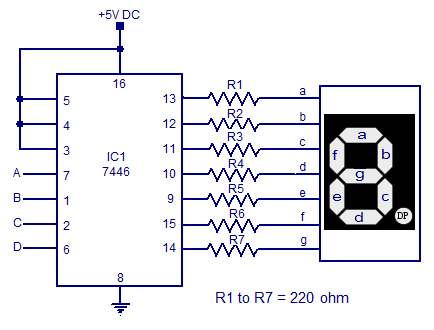

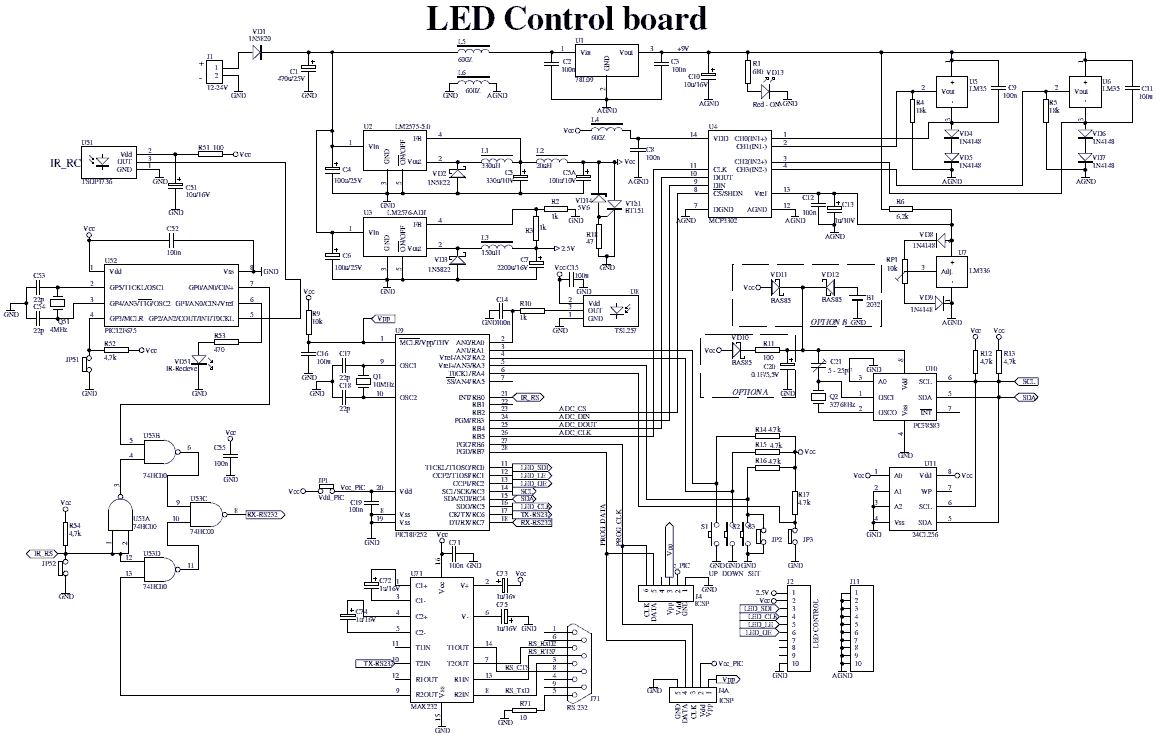

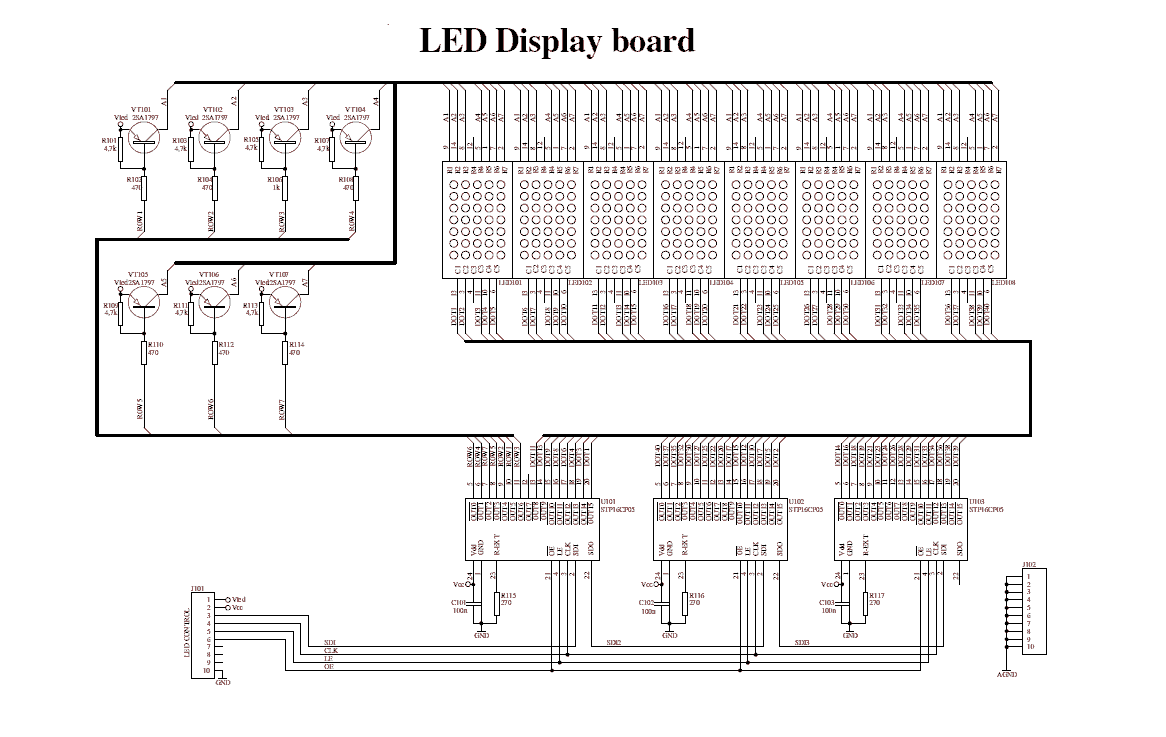

The device comprises two parts: LED control board and LED display board. The two PCBs are designed to fit together one behind the other using two sets of dual row connectors and 4 spacers. One of these connectors is used for the electrical connections, while the other is only used as a mechanical connecting element. The core of the device is microcontroller PIC18F252 (U9). It controls all the functions of the device, generates the overall algorithm to control the LED matrix. LEDs are connected in matrix 40x7. The columns tie together the cathodes of the LEDs and rows tie the LEDs anodes. The LED matrix is controlled dynamically in row by row. To save space and number of components, the LEDs are driven with specialized LED driver STP16CP05 (U101-U103), produced by ST Microelectronics. Each of these ICs contains a 16-bit serial-in, parallel-out shift register, latch register, and 16 constant current output channels. Outputs are open drain type, allowing connection of a load supplied with up to 20V supply voltage. The constant current for all outputs varies from 5 to 100 mA and is set from an external resistor (R115-R117). In this application, the three LED drivers are connected in a cascade and controlled from the microcontroller over SPI protocol. The microcontroller sends a 48-bit word, controlling one row at a time. The 40 LSB represent LED states (1-On, 0-Off) in the row and control their cathodes. The 7 MSB control the anodes through the 7 driver transistors (VT101 - VT107). The 40th bit remains unused. The microcontroller sends the 48-bit word every 1 ms.

There are 7 cycles to display each row plus an extra blank cycle, used to process temperature measurements. Thus, the refresh rate of the display is 125Hz. To control the display brightness, the "outputs enable" (OE) pin is used. Each row cycle begins with a logical 0 on the OE pin (outputs are enabled). The duration of an enabled signal changes depending on the desired brightness, using the microcontroller's on-chip PWM module.

LED dot matrix display 40x7;

- Display of clock, calendar, inside and outside temperature, text messages;

- Automatic Daylight Savings Time;

- Capability of keeping the real-time clock working correctly for more than one week without power supply;

- Inside temperature measurement (0 ÷ +75) °C, ±0.5 °C accuracy;

- Outside temperature measurement (-40 ÷ +75) °C, ±0.5 °C accuracy;

- Supports static and running messages with different effects;

- Full Cyrillic and special symbols support;

- Memory for 10 messages, each including up to 250 symbols;

- Automatic brightness control;

- IR remote control for settings messages select;

- Power supply: 12 ÷ 24V DC;

- Front panel dimensions 305 x 69 mm.

The LED display system operates with a dual-board configuration where the LED control board interfaces with the LED display board through dual row connectors, facilitating both electrical connections and structural integrity. The microcontroller PIC18F252 serves as the central processing unit, executing control algorithms to manage the LED matrix configuration. The matrix is structured in a 40x7 format, with cathodes connected in columns and anodes in rows, allowing for an efficient dynamic control method.

To minimize component count and space on the PCB, the design incorporates three STP16CP05 LED driver ICs, which facilitate the driving of the matrix with constant current outputs. The open-drain outputs of these drivers enable flexible voltage supply options, accommodating loads up to 20V, while the external resistors (R115-R117) provide adjustable current settings for each output channel.

Communication between the microcontroller and the LED drivers occurs via the SPI protocol, where a 48-bit data word is transmitted to control the LED states for each row sequentially. The arrangement of the LED outputs does not follow a linear mapping to the driver pins, which is addressed through software to ensure that the physical layout corresponds accurately to the intended display output.

The system is designed to refresh the display at a rate of 125Hz, balancing the need for responsiveness with the processing overhead required for temperature measurement and display updates. Automatic brightness control is achieved through PWM modulation, allowing the user to adjust display visibility based on ambient light conditions.

The device features a comprehensive set of functionalities, including real-time clock capabilities, temperature measurements, and the ability to display messages with various effects. It also supports a wide range of character sets and has memory for storing multiple messages. Power supply requirements range from 12V to 24V DC, and the physical dimensions of the front panel have been optimized for user interaction and visibility.The device comprises two parts: LED control board and LED display board. The two PCBs are designed to fit together one behind the other using two sets of dual row connectors and 4 spacers. One of this connector is used for the electrical connections, while the other is only used as a mechanical connecting element.

The core of the device is microcontroller PIC18F252 (U9). It controls all the functions of the device, generates the overall algorithm to control the LED matrix. LEDs are connected in matrix 40x7. The columns tie together the cathodes of the LEDs and rows tie the LEDs anodes. The LED matrix is controlled dynamically in row by row. To safe space and number of components, the LEDs are driven with specialized LED driver STP16CP05 (U101-U103), produced by ST Microelectronics. Each of these IC contain 16-bit serial-in, parallel-out shift register, latch register and 16 constant current output channels.

Outputs are open drain type, allowing connection of a load supplied with up to 20V supply voltage. The constant current for all outputs varies from 5 to 100 mA and is set from an external resistor (R115-R117). In this application, the three LED drivers are connected in a cascade and controlled from the microcontroller over SPI protocol.

The microcontroller sends a 48-bit word, controlling one row at the time. The 40 LSB represent LED states (1-On, 0-Off) in the row and control their cathodes. The 7 MSB control the anodes through the 7 driver transistors (VT101 - VT107). The 40th bit remains unused. The microcontroller sends the 48-bit word every 1 ms. There are 7 cycles to display each row plus an extra blank cycle, used to process temperature measurements. Thus, the refresh rate of the display is 125Hz. To control the display brightness is used the "outputs enable" (OE) pin. Each row cycle begins with logical 0 on the OE pin (outputs are enabled). The duration of an enabled signal changes depending on the desired brightness, using the microcontroller's on-chip PWM module.

You should note that numbers of columns and rows are not sequential to the corresponding pins of the ICs (U101-U103). This aims to simplify the design of PCB. The LEDs' corresponding bits are rearranged by software to fit with their physical order. LED dot matrix display 40x7; - Display of clock, calendar, inside and outside temperature, text messages; - Automatic Daylight Savings Time; - Capability of keeping the real time clock working correctly for more than one week without power supply; - Inside temperature measurement (0 ÷ +75) °C, ±0.5 °C accuracy; - Outside temperature measurement (-40 ÷ +75) °C, ±0.5 °C accuracy; - Supports static and running messages with different effects; - Full Cyrillic and special symbols supports; - Memory for 10 messages, each including up to 250 symbols; - Automatic brightness control; - IR remote control for settings messages select; - Power supply: 12 ÷ 24V DC; - Front panel dimensions 305 x 69 mm.

🔗 External reference

There are 7 cycles to display each row plus an extra blank cycle, used to process temperature measurements. Thus, the refresh rate of the display is 125Hz. To control the display brightness, the "outputs enable" (OE) pin is used. Each row cycle begins with a logical 0 on the OE pin (outputs are enabled). The duration of an enabled signal changes depending on the desired brightness, using the microcontroller's on-chip PWM module.

LED dot matrix display 40x7;

- Display of clock, calendar, inside and outside temperature, text messages;

- Automatic Daylight Savings Time;

- Capability of keeping the real-time clock working correctly for more than one week without power supply;

- Inside temperature measurement (0 ÷ +75) °C, ±0.5 °C accuracy;

- Outside temperature measurement (-40 ÷ +75) °C, ±0.5 °C accuracy;

- Supports static and running messages with different effects;

- Full Cyrillic and special symbols support;

- Memory for 10 messages, each including up to 250 symbols;

- Automatic brightness control;

- IR remote control for settings messages select;

- Power supply: 12 ÷ 24V DC;

- Front panel dimensions 305 x 69 mm.

The LED display system operates with a dual-board configuration where the LED control board interfaces with the LED display board through dual row connectors, facilitating both electrical connections and structural integrity. The microcontroller PIC18F252 serves as the central processing unit, executing control algorithms to manage the LED matrix configuration. The matrix is structured in a 40x7 format, with cathodes connected in columns and anodes in rows, allowing for an efficient dynamic control method.

To minimize component count and space on the PCB, the design incorporates three STP16CP05 LED driver ICs, which facilitate the driving of the matrix with constant current outputs. The open-drain outputs of these drivers enable flexible voltage supply options, accommodating loads up to 20V, while the external resistors (R115-R117) provide adjustable current settings for each output channel.

Communication between the microcontroller and the LED drivers occurs via the SPI protocol, where a 48-bit data word is transmitted to control the LED states for each row sequentially. The arrangement of the LED outputs does not follow a linear mapping to the driver pins, which is addressed through software to ensure that the physical layout corresponds accurately to the intended display output.

The system is designed to refresh the display at a rate of 125Hz, balancing the need for responsiveness with the processing overhead required for temperature measurement and display updates. Automatic brightness control is achieved through PWM modulation, allowing the user to adjust display visibility based on ambient light conditions.

The device features a comprehensive set of functionalities, including real-time clock capabilities, temperature measurements, and the ability to display messages with various effects. It also supports a wide range of character sets and has memory for storing multiple messages. Power supply requirements range from 12V to 24V DC, and the physical dimensions of the front panel have been optimized for user interaction and visibility.The device comprises two parts: LED control board and LED display board. The two PCBs are designed to fit together one behind the other using two sets of dual row connectors and 4 spacers. One of this connector is used for the electrical connections, while the other is only used as a mechanical connecting element.

The core of the device is microcontroller PIC18F252 (U9). It controls all the functions of the device, generates the overall algorithm to control the LED matrix. LEDs are connected in matrix 40x7. The columns tie together the cathodes of the LEDs and rows tie the LEDs anodes. The LED matrix is controlled dynamically in row by row. To safe space and number of components, the LEDs are driven with specialized LED driver STP16CP05 (U101-U103), produced by ST Microelectronics. Each of these IC contain 16-bit serial-in, parallel-out shift register, latch register and 16 constant current output channels.

Outputs are open drain type, allowing connection of a load supplied with up to 20V supply voltage. The constant current for all outputs varies from 5 to 100 mA and is set from an external resistor (R115-R117). In this application, the three LED drivers are connected in a cascade and controlled from the microcontroller over SPI protocol.

The microcontroller sends a 48-bit word, controlling one row at the time. The 40 LSB represent LED states (1-On, 0-Off) in the row and control their cathodes. The 7 MSB control the anodes through the 7 driver transistors (VT101 - VT107). The 40th bit remains unused. The microcontroller sends the 48-bit word every 1 ms. There are 7 cycles to display each row plus an extra blank cycle, used to process temperature measurements. Thus, the refresh rate of the display is 125Hz. To control the display brightness is used the "outputs enable" (OE) pin. Each row cycle begins with logical 0 on the OE pin (outputs are enabled). The duration of an enabled signal changes depending on the desired brightness, using the microcontroller's on-chip PWM module.

You should note that numbers of columns and rows are not sequential to the corresponding pins of the ICs (U101-U103). This aims to simplify the design of PCB. The LEDs' corresponding bits are rearranged by software to fit with their physical order. LED dot matrix display 40x7; - Display of clock, calendar, inside and outside temperature, text messages; - Automatic Daylight Savings Time; - Capability of keeping the real time clock working correctly for more than one week without power supply; - Inside temperature measurement (0 ÷ +75) °C, ±0.5 °C accuracy; - Outside temperature measurement (-40 ÷ +75) °C, ±0.5 °C accuracy; - Supports static and running messages with different effects; - Full Cyrillic and special symbols supports; - Memory for 10 messages, each including up to 250 symbols; - Automatic brightness control; - IR remote control for settings messages select; - Power supply: 12 ÷ 24V DC; - Front panel dimensions 305 x 69 mm.

🔗 External reference