Electric Field Mill Fabrication

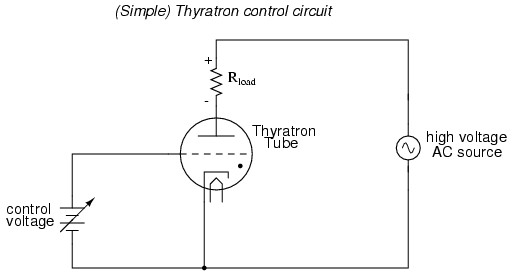

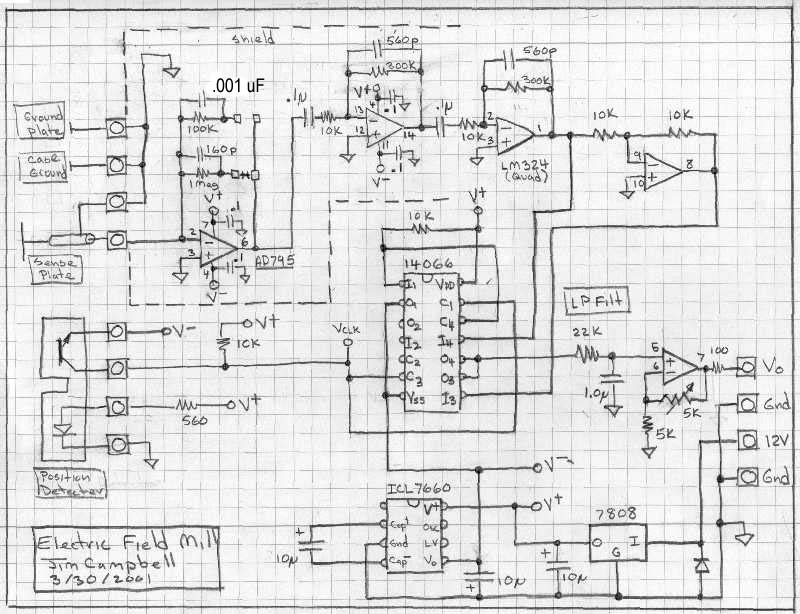

This page outlines the construction of an electric field mill, a device used to measure the electric field strength on Earth due to static electric fields and the charge of clouds overhead. It can also investigate the effects of static electricity. The body and chopper of the field mill are made from a 4-inch diameter duct fan. The signal conditioning electronics utilize a chopper blade position detector and a synchronous detector to minimize noise and recover both the field sign (positive or negative) and magnitude (strength in V/m). The electric field strength can theoretically be measured by placing a voltmeter across plates spaced apart. However, due to the input impedance of the meter (typically 10 Meg), any voltage induced on the plates would quickly dissipate, rendering it ineffective for measuring static fields. To measure the static field, the chopper technique is employed. The chopper blade is positioned over the Sense Plate and rotates to periodically shield and expose the Sense Plate to the electric field. The rotor must be grounded for this to function correctly. The Sense Plate is grounded through a transconductance amplifier that converts the ground current from the Sense Plate into a voltage. As the Sense Plate is exposed to the electric field, it induces ground currents by attracting or repelling charge. When the plate is shielded from the field, the induced charge dissipates. Thus, the chopper creates an AC ground current proportional to the electric field strength. This AC signal can be rectified to drive a DC voltmeter or displayed on an oscilloscope. However, this method only measures the magnitude of the field, not its sign, and any noise present in the signal can also affect the output. The signal conditioning for the field mill employs a synchronous demodulation technique to retain field sign information and minimize noise. The blade position is detected using an LED and phototransistor. The position sensor clock signal amplifies the AC signal from the Sense Plate amplifier by either +1 or -1, depending on the rotor blade position, effectively synchronously rectifying the AC signal and preserving its sign. The rectified signal is then low-pass filtered to eliminate ripple. Alternatively, this circuit can be viewed as mixing two identical frequencies, resulting in output with frequency content at DC and twice the input frequency. The low-pass filter passes only the DC component, effectively rejecting noise at frequencies other than the position clock frequency.

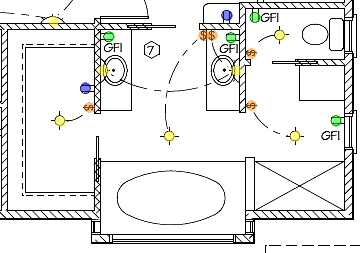

To construct the electric field mill, cut three strips of brass (approximately 0.5 x 2 inches), fold them in half, and drill holes so that the ledge is about 1.5 inches down from the top. Attach the plastic sensor plate hardware to the brackets and mount them inside the housing as illustrated. Drill a hole through a piece of 0.5-inch diameter Delrin, matching the motor shaft size, and drill and tap set screws. Cut a piece of stock the same size as the shaft and mount it as shown. Note that grounding the chopper rotor is essential, which may allow for fabrication of the mill without extending the shaft. It was necessary to cut the end off the motor shaft to fit the extender back sufficiently, resulting in some wobble on the extended shaft. Alternatively, the motor could be repositioned forward if necessary. Lay the chopper blades on a sheet of 0.015-inch thick brass, trace the outline of the chopper plate with a scribe, and cut it out using tin snips. Drill the center and cut to size using a nibbling tool.This page describes the construction of an electric field mill. This is a device to measure the electric field strength on earth due to the static electric field and the charge of clouds passing overhead. It can also be used to investigate static electricity effects. The body and chopper of the field mill are fabricated from a 4 inch diameter duct fan. The signal conditioning electronics uses a chopper blade position detector and a synchronous detector to reduce noise and recover the field sign (positive or negative) as well as magnitude (strength in V/m). 1. Martin A. Uman - Lightning, McGraw-Hill Book Company, New York (1969), 264 pages. Russian translation (1972), revised edition, Dover, New York (1984). (Available at Borders) The strength of the electric field could be measured, in principle, by placing a volt meter across plates placed some distance apart.

However, because the meter will have some input impedance (10 Meg typically), any voltage induced on the plates will quickly drain away, and would not be useful for measuring the static field. To make measurements of the static field, the chopper technique is used. The chopper blade is arranged over the Sense Plate and rotated so that it periodically shields, and exposes the Sense Plate to the electric field.

To properly do this, the Rotor must be grounded. The Sense Plate is grounded through a transconductance amplifier, which converts the Sense Plate`s ground current to a voltage. As the Sense Plate is exposed to the Field, the field induces ground currents as it attracts or repels charge from the Sense Plate.

As the plate is shielded from the field, the induced charge drains away. So the chopper induces an AC ground current which is proportional to electric field strength. This AC signal could then be rectified to drive a DC volt meter or be plotted on a scope. However, by doing this only the magnitude of the field, not the sign (positive of negative) would be measured. Also, any noise in the signal would also affect the output. The signal conditioning for this Field Mill uses a synchronous demodulation technique to preserve field sign information and reduce noise.

It works like this: The blade position is measured using an LED and photo transistor. The Position Sensor clock signal is used to effectively amplify the AC signal from the Sense Plate amplifier by either +1 or -1, depending on Rotor blade position. This has the effect of synchronously rectifying the AC signal, preserving sign. This rectified signal is then low pass filtered to remove ripple. Alternatively, this circuit function can be thought of as the mixing of two identical frequencies, resulting in output with frequency content at DC, and twice the input frequency.

The low pass filter then passes only the DC component. This line of thought will also show how noise at frequencies other that the position clock frequency are rejected. Cut 3 stripes of brass (about. 5 x 2 inches), fold about in half and drill. Drill three holes so that the ledge is about 1. 5 inches down from the top. Attach the plastic Sensor Plate hardware to the brackets and mount the brackets inside the housing as shown.

Drill a hole (the same size at the motor shaft. ) clean through a piece of. 5 inch diameter delrin. Drill and tap the set screws. Cut a piece of stock the same size as the shaft and mount as shown. Note: My goal was initially to insolate the chopper rotor, but then found grounding was required. So you may be able to fabricate the Mill without having to extend the shaft like this. I did have to cut the end off the motor shaft to fit the extender back far enough, and did end up with some wobble on the extended shaft You could move the whole motor forward as well if needed. Lay the Chopper blades on a sheet of. 015 thick brass. Trace the outline of the chopper plate using a scribe and cut it out using tin snipes. Drill the center and cut to size using a nibbl 🔗 External reference

To construct the electric field mill, cut three strips of brass (approximately 0.5 x 2 inches), fold them in half, and drill holes so that the ledge is about 1.5 inches down from the top. Attach the plastic sensor plate hardware to the brackets and mount them inside the housing as illustrated. Drill a hole through a piece of 0.5-inch diameter Delrin, matching the motor shaft size, and drill and tap set screws. Cut a piece of stock the same size as the shaft and mount it as shown. Note that grounding the chopper rotor is essential, which may allow for fabrication of the mill without extending the shaft. It was necessary to cut the end off the motor shaft to fit the extender back sufficiently, resulting in some wobble on the extended shaft. Alternatively, the motor could be repositioned forward if necessary. Lay the chopper blades on a sheet of 0.015-inch thick brass, trace the outline of the chopper plate with a scribe, and cut it out using tin snips. Drill the center and cut to size using a nibbling tool.This page describes the construction of an electric field mill. This is a device to measure the electric field strength on earth due to the static electric field and the charge of clouds passing overhead. It can also be used to investigate static electricity effects. The body and chopper of the field mill are fabricated from a 4 inch diameter duct fan. The signal conditioning electronics uses a chopper blade position detector and a synchronous detector to reduce noise and recover the field sign (positive or negative) as well as magnitude (strength in V/m). 1. Martin A. Uman - Lightning, McGraw-Hill Book Company, New York (1969), 264 pages. Russian translation (1972), revised edition, Dover, New York (1984). (Available at Borders) The strength of the electric field could be measured, in principle, by placing a volt meter across plates placed some distance apart.

However, because the meter will have some input impedance (10 Meg typically), any voltage induced on the plates will quickly drain away, and would not be useful for measuring the static field. To make measurements of the static field, the chopper technique is used. The chopper blade is arranged over the Sense Plate and rotated so that it periodically shields, and exposes the Sense Plate to the electric field.

To properly do this, the Rotor must be grounded. The Sense Plate is grounded through a transconductance amplifier, which converts the Sense Plate`s ground current to a voltage. As the Sense Plate is exposed to the Field, the field induces ground currents as it attracts or repels charge from the Sense Plate.

As the plate is shielded from the field, the induced charge drains away. So the chopper induces an AC ground current which is proportional to electric field strength. This AC signal could then be rectified to drive a DC volt meter or be plotted on a scope. However, by doing this only the magnitude of the field, not the sign (positive of negative) would be measured. Also, any noise in the signal would also affect the output. The signal conditioning for this Field Mill uses a synchronous demodulation technique to preserve field sign information and reduce noise.

It works like this: The blade position is measured using an LED and photo transistor. The Position Sensor clock signal is used to effectively amplify the AC signal from the Sense Plate amplifier by either +1 or -1, depending on Rotor blade position. This has the effect of synchronously rectifying the AC signal, preserving sign. This rectified signal is then low pass filtered to remove ripple. Alternatively, this circuit function can be thought of as the mixing of two identical frequencies, resulting in output with frequency content at DC, and twice the input frequency.

The low pass filter then passes only the DC component. This line of thought will also show how noise at frequencies other that the position clock frequency are rejected. Cut 3 stripes of brass (about. 5 x 2 inches), fold about in half and drill. Drill three holes so that the ledge is about 1. 5 inches down from the top. Attach the plastic Sensor Plate hardware to the brackets and mount the brackets inside the housing as shown.

Drill a hole (the same size at the motor shaft. ) clean through a piece of. 5 inch diameter delrin. Drill and tap the set screws. Cut a piece of stock the same size as the shaft and mount as shown. Note: My goal was initially to insolate the chopper rotor, but then found grounding was required. So you may be able to fabricate the Mill without having to extend the shaft like this. I did have to cut the end off the motor shaft to fit the extender back far enough, and did end up with some wobble on the extended shaft You could move the whole motor forward as well if needed. Lay the Chopper blades on a sheet of. 015 thick brass. Trace the outline of the chopper plate using a scribe and cut it out using tin snipes. Drill the center and cut to size using a nibbl 🔗 External reference