Home-Built Pulsed Multiple Gas (PMG) Laser

The Pulsed Multiple Gas (PMG) laser discussed in this chapter closely resembles the Home-Built Pulsed Argon and/or Krypton (Ar/Kr) Ion Laser from Scientific American. However, the PMG laser's developers have also utilized xenon (Xe) and oxygen (O2) and even propose that ordinary air may be effective as well. Although not covered in the original reference, it is plausible that with the appropriate mirrors, pure neon and other gases could also lase using this basic configuration. The primary differences lie in the power supply design. Instead of employing a simple rectified neon sign transformer and an Oudin/Tesla coil trigger, it utilizes a 15 kV thyratron-controlled pulsar in the basic power supply, featuring a more intricate design that allows for improved control over pulse width and energy. This "cascade" system incorporates a high voltage trigger and a lower voltage pulse forming network, akin to systems used to drive xenon strobes or solid-state lasers. When operating with argon or krypton, some of the same wavelengths are emitted as with standard Ar/Kr ion lasers. It is assumed that xenon behaves similarly, although data for a xenon ion laser is lacking. The Xe lines can lase with both the simple exciter and the cascade system, while most Ar and Kr lines necessitate the cascade system. The lasing mechanism for O2 remains uncertain, as it may differ significantly due to being a non-noble gas diatomic molecule. No data is available regarding O2 with the cascade system, suggesting that O2 lines may not lase with a broad, lower voltage pulse. In this scenario, lasing may occur in the afterglow, as suggested by some sources, operating solely with the short high voltage pulse provided directly by the simple exciter's thyratron. The PMG laser is expected to produce coherent light at orange (611.9 nm) and yellow (594.1 nm) wavelengths with pure neon (Ne), similar to the non-red HeNe lasers. The construction of the PMG laser is comparable to that of the Ar/Kr ion laser in terms of complexity. A flowing gas system, akin to an axial flow CO2 laser, is recommended, utilizing a mechanical pump at one end of the laser tube and a controlled gas leak valve at the opposite end. A medium vacuum system and some glasswork will be necessary. However, the use of readily available O2 simplifies gas handling compared to Ar/Kr ion or HeNe lasers. The home-built PMG laser may produce an average power beam of several tens of milliwatts across multiple wavelengths. Due to the lack of definitive information regarding the actual power output of this or similar home-built laser designs, it is crucial to exercise caution, assuming a higher power output until verified otherwise. The authors estimate a peak power of around 10 W, although this figure may be speculative. The power supplies pose lethal risks, as either high voltage supply can generate sufficient voltage and current to induce cardiac arrest. For instance, a 1 µF capacitor charged to 15 kV stores over 11 joules, while the pulse forming network in the cascade system can store over 35 joules. Even if a shock does not result in fatality, it may cause involuntary reactions leading to potential harm. It is imperative to adhere to Safety Guidelines for High Voltage and/or Line Powered Equipment. All connections must be insulated, and barriers should be installed to prevent contact with high voltage. When water cooling is employed, these precautions become even more critical, as water and high voltage electricity can create hazardous conditions. Notably, using oxygen in the laser increases fire risk in the event of a significant gas leak or failure of the regulator/metering valve, resulting in atmospheric pressure changes.

The PMG laser system consists of several key components, including the gas chamber, optical resonator, power supply, and cooling system. The gas chamber is designed to contain the lasing medium and is constructed from materials that can withstand high pressures and temperatures. The optical resonator typically consists of two mirrors: one highly reflective and the other partially reflective, allowing for the emission of laser light while maintaining the necessary feedback for the lasing process.

In operation, the power supply generates high voltage pulses that ionize the gas within the chamber, creating a plasma state conducive to laser action. The cascade system is particularly effective in shaping the pulse characteristics, ensuring that the energy delivered to the gas is optimized for efficient lasing. The choice of gas significantly influences the wavelengths produced, with different gases providing distinct spectral lines.

Safety measures must be meticulously implemented throughout the design and operation of the PMG laser. This includes robust insulation of all electrical components, the use of safety barriers, and clear labeling of high voltage areas. Furthermore, the gas handling system must be designed to prevent leaks and ensure safe operation under varying atmospheric conditions.

In summary, the PMG laser represents a versatile and innovative approach to laser technology, capable of utilizing a variety of gases and offering significant potential for experimentation and application in various fields. However, due to the inherent risks associated with high voltage and the use of reactive gases, careful design, and adherence to safety protocols are paramount for successful and safe operation.The Pulsed Multiple Gas (PMG) laser described in this chapter is very similar in many ways to the Home-Built Pulsed Argon and/or Krypton (Ar/Kr) Ion Laser from Scientific American. However, the developers of the PMG laser have also used it with xenon (Xe) oxygen (O2), and even suggest that plain old ordinary air might work as well!

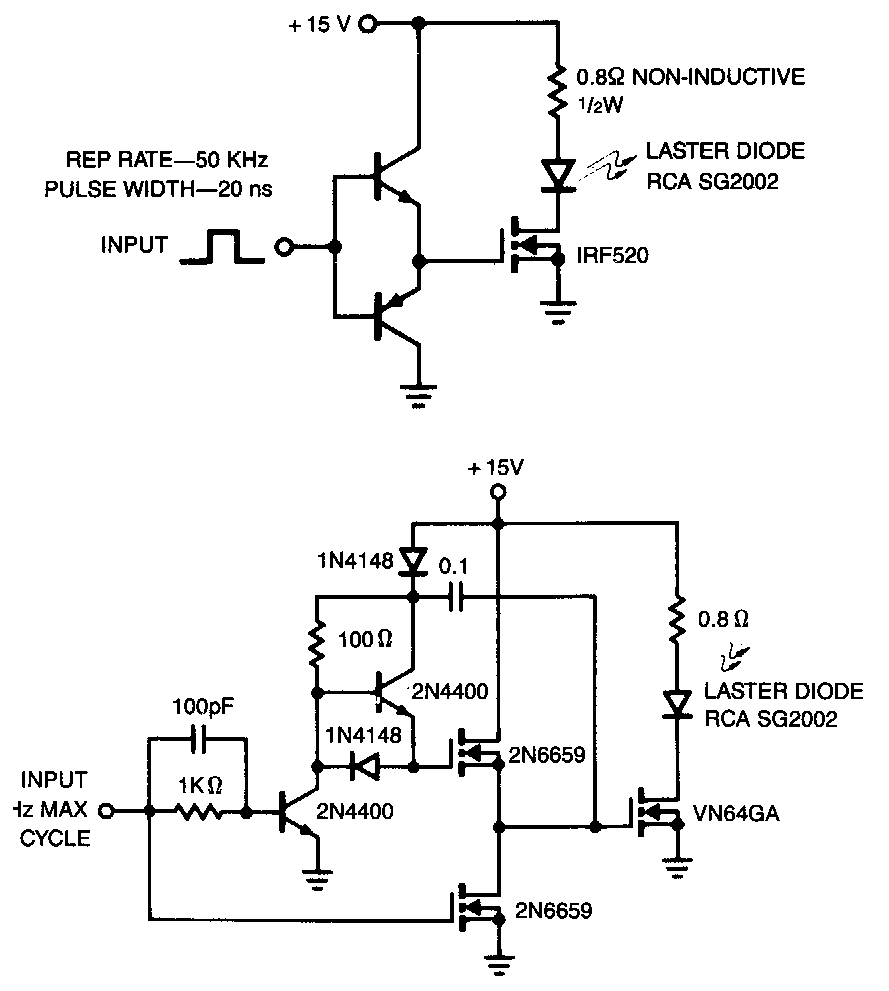

Though not cove red in the original reference, it is also likely that with the appropriate mirrors, pure neon as well as other gases will lase with this same basic setup. Most of the major differences are with respect to the power supply. Rather than a simple rectified neon sign transformer and Oudin/Tesla coil trigger, it uses a 15 kV thyratron controlled pulsar in the basic power supply and also includes a more complex design capable of better control of pulse width and energy.

This `cascade` system includes a high voltage trigger and lower voltage pulse forming network - similar in some ways to what is used to drive a xenon strobe or solid state laser. When used with argon or krypton, some of the same wavelengths are produced as with normal Ar/Kr ion lasers.

I assume this to be the case with xenon as well but I don`t have any data for a xenon ion laser. The Xe lines lase with both the simple exciter as well as the cascade system though most of the Ar and Kr lines require the cascade system. I also don`t know if the O2 lasing process is similar - it could very well be a totally different mechanism being a non-noble gas diatonic molecule.

No data is available for O2 with the cascade system. This indicates that the O2 lines may not lase with a wide, lower voltage pulse. In this case, it could be lasing in the afterglow (as has been suggested by some people) which would only operate with the short HV pulse provided by the simple exciter`s thyratron directly. With pure neon (Ne), the PMG laser should produce coherent light at the orange (611. 9 nm) and yellow (594. 1 nm) wavelengths of the corresponding non-red HeNe lasers. This is discussed in more detail later in this chapter. And, you are of course free to try whatever other gases you desire! The PMG laser is also very similar in many respects to the Ar/Kr ion laser in terms of the difficulty of construction.

A flowing gas system like that of an axial flow CO2 laser is suggested - a mechanical pump at one end of the laser tube and a controlled gas leak valve at the other end. A medium vacuum system and some glass work will be needed. However, since easily obtained (or generated) O2 can be used, the gas handling can be much simpler than for the Ar/Kr ion or HeNe lasers.

Laser output: The home-built PMG laser may be capable of producing a beam with an average power of several 10s of mW at multiple wavelengths. Since there doesn`t seem to be any hard information on the actual power obtainable with this or similar home-built laser designs, it is important to take precautions assuming a higher power until determined otherwise.

The authors suggest peak power of around 10 W - I don`t know if this is much more than a guess, however. Electrical: The power supplies can be lethal. Either of the high voltage power supplies easily have enough voltage and current to stop a heart. A. 1 uF capacitor charged to 15 kV stores more than 11 joules. The pulse forming network in the cascade system stores over 35 J. Even if you aren`t killed, the shock may startle you into doing something you might regret. Make sure you read and follow the Safety Guidelines for High Voltage and/or Line Powered Equipment. Insulate all connections and install barriers to prevent contact with the high voltage. Where water cooling is used, these precautions are even more critical as water and high voltage electricity don`t make a happy combination.

Gases: In particular, if you use oxygen in your laser, there is increased fire risk should there be a serious gas leak or regulator/metering valve failure resulting in atmospheric press 🔗 External reference

The PMG laser system consists of several key components, including the gas chamber, optical resonator, power supply, and cooling system. The gas chamber is designed to contain the lasing medium and is constructed from materials that can withstand high pressures and temperatures. The optical resonator typically consists of two mirrors: one highly reflective and the other partially reflective, allowing for the emission of laser light while maintaining the necessary feedback for the lasing process.

In operation, the power supply generates high voltage pulses that ionize the gas within the chamber, creating a plasma state conducive to laser action. The cascade system is particularly effective in shaping the pulse characteristics, ensuring that the energy delivered to the gas is optimized for efficient lasing. The choice of gas significantly influences the wavelengths produced, with different gases providing distinct spectral lines.

Safety measures must be meticulously implemented throughout the design and operation of the PMG laser. This includes robust insulation of all electrical components, the use of safety barriers, and clear labeling of high voltage areas. Furthermore, the gas handling system must be designed to prevent leaks and ensure safe operation under varying atmospheric conditions.

In summary, the PMG laser represents a versatile and innovative approach to laser technology, capable of utilizing a variety of gases and offering significant potential for experimentation and application in various fields. However, due to the inherent risks associated with high voltage and the use of reactive gases, careful design, and adherence to safety protocols are paramount for successful and safe operation.The Pulsed Multiple Gas (PMG) laser described in this chapter is very similar in many ways to the Home-Built Pulsed Argon and/or Krypton (Ar/Kr) Ion Laser from Scientific American. However, the developers of the PMG laser have also used it with xenon (Xe) oxygen (O2), and even suggest that plain old ordinary air might work as well!

Though not cove red in the original reference, it is also likely that with the appropriate mirrors, pure neon as well as other gases will lase with this same basic setup. Most of the major differences are with respect to the power supply. Rather than a simple rectified neon sign transformer and Oudin/Tesla coil trigger, it uses a 15 kV thyratron controlled pulsar in the basic power supply and also includes a more complex design capable of better control of pulse width and energy.

This `cascade` system includes a high voltage trigger and lower voltage pulse forming network - similar in some ways to what is used to drive a xenon strobe or solid state laser. When used with argon or krypton, some of the same wavelengths are produced as with normal Ar/Kr ion lasers.

I assume this to be the case with xenon as well but I don`t have any data for a xenon ion laser. The Xe lines lase with both the simple exciter as well as the cascade system though most of the Ar and Kr lines require the cascade system. I also don`t know if the O2 lasing process is similar - it could very well be a totally different mechanism being a non-noble gas diatonic molecule.

No data is available for O2 with the cascade system. This indicates that the O2 lines may not lase with a wide, lower voltage pulse. In this case, it could be lasing in the afterglow (as has been suggested by some people) which would only operate with the short HV pulse provided by the simple exciter`s thyratron directly. With pure neon (Ne), the PMG laser should produce coherent light at the orange (611. 9 nm) and yellow (594. 1 nm) wavelengths of the corresponding non-red HeNe lasers. This is discussed in more detail later in this chapter. And, you are of course free to try whatever other gases you desire! The PMG laser is also very similar in many respects to the Ar/Kr ion laser in terms of the difficulty of construction.

A flowing gas system like that of an axial flow CO2 laser is suggested - a mechanical pump at one end of the laser tube and a controlled gas leak valve at the other end. A medium vacuum system and some glass work will be needed. However, since easily obtained (or generated) O2 can be used, the gas handling can be much simpler than for the Ar/Kr ion or HeNe lasers.

Laser output: The home-built PMG laser may be capable of producing a beam with an average power of several 10s of mW at multiple wavelengths. Since there doesn`t seem to be any hard information on the actual power obtainable with this or similar home-built laser designs, it is important to take precautions assuming a higher power until determined otherwise.

The authors suggest peak power of around 10 W - I don`t know if this is much more than a guess, however. Electrical: The power supplies can be lethal. Either of the high voltage power supplies easily have enough voltage and current to stop a heart. A. 1 uF capacitor charged to 15 kV stores more than 11 joules. The pulse forming network in the cascade system stores over 35 J. Even if you aren`t killed, the shock may startle you into doing something you might regret. Make sure you read and follow the Safety Guidelines for High Voltage and/or Line Powered Equipment. Insulate all connections and install barriers to prevent contact with the high voltage. Where water cooling is used, these precautions are even more critical as water and high voltage electricity don`t make a happy combination.

Gases: In particular, if you use oxygen in your laser, there is increased fire risk should there be a serious gas leak or regulator/metering valve failure resulting in atmospheric press 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713