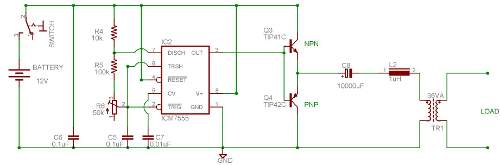

Inverter Schematics

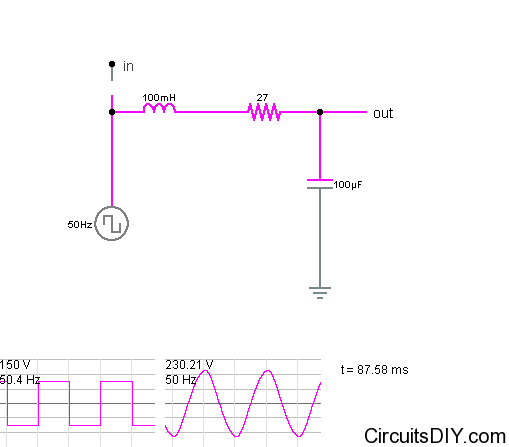

A small bias on the bases of Q1 and Q2 through R1 and R2 assists in initiating the circuit. This provides each transistor's base with a slight forward bias, enabling both transistors to conduct when the circuit is initially powered on. The base voltage on each transistor is zero at startup; thus, the small forward bias through R1 and R2 results in a voltage above zero at each base. The incorporation of integrated circuit (IC) timing or clock circuitry, along with high-quality core materials for the transformers and possibly JFETs, will enhance accuracy and reduce losses, thereby making the inverter more efficient. The transformers' coils and cores need to be adequately sized, as the required output frequency is 60 Hz. If this circuit functions as part of a DC to DC converter or for frequency inversion (input at low Hz, output at high Hz), the clock circuitry can be configured for a higher frequency, such as 40 kHz or any desired output frequency. Operating in this higher frequency range will significantly reduce the size of the transformers, which also improves efficiency by minimizing core losses, winding losses, and heat losses due to winding resistance and core reluctance.

The circuit design incorporates a biasing network consisting of resistors R1 and R2, which are strategically connected to the bases of transistors Q1 and Q2. This arrangement ensures that both transistors receive an initial forward bias, allowing them to enter conduction mode promptly when power is applied. The choice of resistors is critical; their values must be selected to provide sufficient biasing without overwhelming the base-emitter junctions of the transistors.

The use of integrated circuit timing circuitry is a significant enhancement to the inverter's operation. This circuitry can generate precise timing signals that control the switching of the transistors, leading to improved performance and reliability. High-quality core materials for the transformers are essential to minimize losses associated with magnetic hysteresis and eddy currents. The inclusion of JFETs may provide additional benefits, such as lower on-resistance and faster switching times, further optimizing the inverter's efficiency.

Transformer design is crucial for achieving the desired output frequency of 60 Hz. The physical dimensions of the transformer coils and cores must be sufficient to handle the required power levels while maintaining operational efficiency. If the circuit is intended for frequency inversion, the clock circuitry can be adjusted to operate at higher frequencies, such as 40 kHz. This adjustment allows for smaller transformer designs, which can lead to reduced core and winding losses. Additionally, operating at higher frequencies can help mitigate thermal issues associated with resistive losses, thereby enhancing the overall performance of the inverter system.

In summary, careful consideration of biasing, timing circuitry, transformer design, and component selection is vital for creating an efficient inverter circuit capable of meeting the specified operational requirements.A small bias on the bases of Q1 and Q2 via R1 and R2, assists in "starting" This gives each transistor`s base a small forward bias, so that both transistors tend to conduct when the circuit is first switched on [the base voltage on each transistor is zero when circuit is first switched on, so the small forward biasing thru R1 and R2 results in an above zero voltage at each base]. Use of IC timing [clock] circuitry, along with quality core materials for the transformers and possibly JFET`s wil increase the accuracy, and decrease the losses, making the Inverter more efficient. The transformers` coils and cores will need to be large, since the output Hz required is 60Hz. If this was part of a DC to DC converter, or if this was used for Frequency Inversion [input = low Hz, output = High Hz], then the clock circuitry can be set for a higher Hz.

like 40KHz [or what ever the output Hz will be]. Being up in that range will reduce the size of the transformers dramatically - which also increases efficiency by decreasing core losses, winding losses and losses from heat [winding resistance, core`s reluctance, etc. ]. 🔗 External reference

The circuit design incorporates a biasing network consisting of resistors R1 and R2, which are strategically connected to the bases of transistors Q1 and Q2. This arrangement ensures that both transistors receive an initial forward bias, allowing them to enter conduction mode promptly when power is applied. The choice of resistors is critical; their values must be selected to provide sufficient biasing without overwhelming the base-emitter junctions of the transistors.

The use of integrated circuit timing circuitry is a significant enhancement to the inverter's operation. This circuitry can generate precise timing signals that control the switching of the transistors, leading to improved performance and reliability. High-quality core materials for the transformers are essential to minimize losses associated with magnetic hysteresis and eddy currents. The inclusion of JFETs may provide additional benefits, such as lower on-resistance and faster switching times, further optimizing the inverter's efficiency.

Transformer design is crucial for achieving the desired output frequency of 60 Hz. The physical dimensions of the transformer coils and cores must be sufficient to handle the required power levels while maintaining operational efficiency. If the circuit is intended for frequency inversion, the clock circuitry can be adjusted to operate at higher frequencies, such as 40 kHz. This adjustment allows for smaller transformer designs, which can lead to reduced core and winding losses. Additionally, operating at higher frequencies can help mitigate thermal issues associated with resistive losses, thereby enhancing the overall performance of the inverter system.

In summary, careful consideration of biasing, timing circuitry, transformer design, and component selection is vital for creating an efficient inverter circuit capable of meeting the specified operational requirements.A small bias on the bases of Q1 and Q2 via R1 and R2, assists in "starting" This gives each transistor`s base a small forward bias, so that both transistors tend to conduct when the circuit is first switched on [the base voltage on each transistor is zero when circuit is first switched on, so the small forward biasing thru R1 and R2 results in an above zero voltage at each base]. Use of IC timing [clock] circuitry, along with quality core materials for the transformers and possibly JFET`s wil increase the accuracy, and decrease the losses, making the Inverter more efficient. The transformers` coils and cores will need to be large, since the output Hz required is 60Hz. If this was part of a DC to DC converter, or if this was used for Frequency Inversion [input = low Hz, output = High Hz], then the clock circuitry can be set for a higher Hz.

like 40KHz [or what ever the output Hz will be]. Being up in that range will reduce the size of the transformers dramatically - which also increases efficiency by decreasing core losses, winding losses and losses from heat [winding resistance, core`s reluctance, etc. ]. 🔗 External reference