line powered white leds

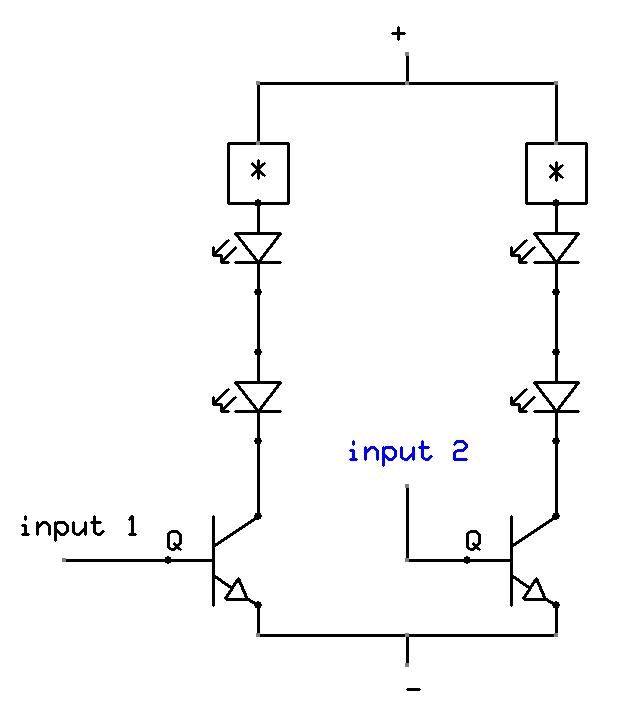

The LED circuit illustrated below features 25 white LEDs connected in series to a 120VAC power supply. This configuration can be adjusted to accommodate a different number of LEDs by modifying the resistor value. The specific resistance required will depend on the characteristics of the LEDs employed. However, calculating the appropriate resistor value can be complex due to the non-continuous current flow through the resistor.

The described LED circuit operates by connecting multiple white LEDs in series, which allows for a uniform distribution of voltage across each LED. The series connection ensures that the same current flows through all the LEDs, which is crucial for maintaining consistent brightness. When interfacing with a 120VAC power source, it is essential to incorporate a current-limiting resistor to prevent excessive current from damaging the LEDs.

To calculate the required resistance, one must consider the forward voltage drop of each LED, which typically ranges from 2.8V to 3.6V for white LEDs. The total forward voltage drop for 25 LEDs in series would be approximately 70V to 90V. Given the 120VAC supply, the peak voltage (approximately 170V) must also be accounted for, as the LEDs will only conduct during the positive half-cycle of the AC waveform.

The current-limiting resistor can be calculated using Ohm's Law (V = IR). The voltage across the resistor can be determined by subtracting the total forward voltage drop of the LEDs from the peak supply voltage. The formula for the resistor value (R) can be expressed as:

R = (V_peak - V_LED_total) / I

Where:

- V_peak = 170V (peak voltage of the 120VAC supply)

- V_LED_total = Total forward voltage drop of the LEDs (e.g., 75V for 25 LEDs at 3V each)

- I = Desired current through the LEDs, typically in the range of 20mA to 30mA for standard LEDs.

It is important to ensure that the resistor can handle the power dissipation, which can be calculated using P = I²R. Additionally, safety precautions should be taken when working with high-voltage AC circuits, including proper insulation and the use of components rated for the voltage and current levels in the circuit.

This LED circuit design can be adapted for different configurations by altering the number of LEDs and adjusting the resistor value accordingly, ensuring optimal performance and longevity of the LED components.The LED circuit below is an example of using 25 white LEDs in series connected to the 120VAC line. It can be modified for more or less LEDs by adjusting the resistor value. The exact resistance will depend on the particular LEDs used. But working out the resistor value is a bit complicated since current will not continously flow through the resistor.. 🔗 External reference

The described LED circuit operates by connecting multiple white LEDs in series, which allows for a uniform distribution of voltage across each LED. The series connection ensures that the same current flows through all the LEDs, which is crucial for maintaining consistent brightness. When interfacing with a 120VAC power source, it is essential to incorporate a current-limiting resistor to prevent excessive current from damaging the LEDs.

To calculate the required resistance, one must consider the forward voltage drop of each LED, which typically ranges from 2.8V to 3.6V for white LEDs. The total forward voltage drop for 25 LEDs in series would be approximately 70V to 90V. Given the 120VAC supply, the peak voltage (approximately 170V) must also be accounted for, as the LEDs will only conduct during the positive half-cycle of the AC waveform.

The current-limiting resistor can be calculated using Ohm's Law (V = IR). The voltage across the resistor can be determined by subtracting the total forward voltage drop of the LEDs from the peak supply voltage. The formula for the resistor value (R) can be expressed as:

R = (V_peak - V_LED_total) / I

Where:

- V_peak = 170V (peak voltage of the 120VAC supply)

- V_LED_total = Total forward voltage drop of the LEDs (e.g., 75V for 25 LEDs at 3V each)

- I = Desired current through the LEDs, typically in the range of 20mA to 30mA for standard LEDs.

It is important to ensure that the resistor can handle the power dissipation, which can be calculated using P = I²R. Additionally, safety precautions should be taken when working with high-voltage AC circuits, including proper insulation and the use of components rated for the voltage and current levels in the circuit.

This LED circuit design can be adapted for different configurations by altering the number of LEDs and adjusting the resistor value accordingly, ensuring optimal performance and longevity of the LED components.The LED circuit below is an example of using 25 white LEDs in series connected to the 120VAC line. It can be modified for more or less LEDs by adjusting the resistor value. The exact resistance will depend on the particular LEDs used. But working out the resistor value is a bit complicated since current will not continously flow through the resistor.. 🔗 External reference