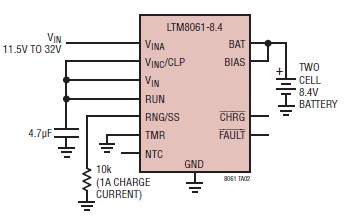

Lithium battery charger schematic circuit design using LTM8061 IC

A simple and efficient lithium battery charger and monitoring system can be designed using the LTM8061 integrated circuit from Linear Technology. The LTM8061 is a high-efficiency 32V, 2A module standalone lithium battery charger optimized for one- and two-cell packs, with fixed float voltage options of 4.1V, 4.2V, 8.2V, and 8.4V. It features a preconditioning function that trickle charges a depleted battery, and includes bad battery detection that signals and suspends charging if the battery does not respond to preconditioning. The LTM8061 can be configured to terminate charging when the charge current drops to one-tenth of the programmed maximum current or can utilize an internal timer for time-based termination. Upon termination of charging, the LTM8061 enters a low current standby mode. If the battery voltage decreases by 2.5% from the float voltage or if a new battery is inserted, the auto-restart feature initiates a new charge cycle. To design a charger using the LTM8061, it is necessary to select the appropriate chip and apply a few equations, particularly if a non-standard configuration is desired, such as limiting the input current.

The LTM8061 integrated circuit serves as a versatile solution for lithium battery charging applications, providing a compact and efficient means to manage battery health and charging cycles. The IC's ability to handle both one-cell and two-cell lithium battery packs makes it suitable for a variety of applications ranging from consumer electronics to industrial devices.

The preconditioning feature is particularly beneficial for maintaining battery longevity, as it allows for a gentle charging process for batteries that have been deeply discharged. This feature mitigates the risks associated with charging batteries that may have developed internal faults, enhancing the overall safety of the charging system.

For applications requiring precise control, the configurable charging termination mechanisms provide flexibility. The choice between current-based and timer-based termination allows designers to tailor the charging process to specific battery characteristics or application needs. The low current standby mode following charge termination is advantageous for energy conservation, reducing power consumption when the charger is not actively charging.

The auto-restart feature is critical for systems that may experience battery voltage drops due to load changes or battery insertion. This ensures that the battery is consistently maintained at its optimal charge level without manual intervention.

In terms of implementation, the selection of the LTM8061 requires careful consideration of the desired float voltage and the specific requirements of the battery being charged. Designers may need to calculate the necessary resistor values to set the float voltage accurately and ensure that the charging current is within safe limits for the battery’s specifications.

Overall, the LTM8061 integrated circuit provides a robust platform for developing lithium battery charging solutions, combining efficiency, safety, and flexibility into a single module.A very simple and efficiency Lithium battery charger and monitoring system, can be designed using the LTM8061 integrated circuit, designed by Linear Technology. The LTM8061 IC is a high efficiency 32V, 2A Module standalone Lithium battery charger optimized for one and two-cell packs, with fixed float voltage options: 4.

1V, 4. 2V, 8. 2V and 8. 4V . A precondition feature trickle charges a depleted battery, and bad battery detection provides a signal and suspends charging if a battery does not respond to preconditioning. The LTM8061 can be configured to terminate charging when charge current falls to one-tenth the programmed maximum current or to use an internal timer if a time based termination scheme is desired.

When charging is terminated, the LTM8061 enters a low current standby mode. If the battery voltage drops 2. 5% from the fl oat voltage, or if a new battery is inserted into a charging system, the auto-restart feature starts a new charge cycle. To design a charger using the LTM8061 IC, you`ll need just to select the right chip and apply few equations ( just in case if you don`t want the standard configuration, for example if you want to limit the input current ).

🔗 External reference

The LTM8061 integrated circuit serves as a versatile solution for lithium battery charging applications, providing a compact and efficient means to manage battery health and charging cycles. The IC's ability to handle both one-cell and two-cell lithium battery packs makes it suitable for a variety of applications ranging from consumer electronics to industrial devices.

The preconditioning feature is particularly beneficial for maintaining battery longevity, as it allows for a gentle charging process for batteries that have been deeply discharged. This feature mitigates the risks associated with charging batteries that may have developed internal faults, enhancing the overall safety of the charging system.

For applications requiring precise control, the configurable charging termination mechanisms provide flexibility. The choice between current-based and timer-based termination allows designers to tailor the charging process to specific battery characteristics or application needs. The low current standby mode following charge termination is advantageous for energy conservation, reducing power consumption when the charger is not actively charging.

The auto-restart feature is critical for systems that may experience battery voltage drops due to load changes or battery insertion. This ensures that the battery is consistently maintained at its optimal charge level without manual intervention.

In terms of implementation, the selection of the LTM8061 requires careful consideration of the desired float voltage and the specific requirements of the battery being charged. Designers may need to calculate the necessary resistor values to set the float voltage accurately and ensure that the charging current is within safe limits for the battery’s specifications.

Overall, the LTM8061 integrated circuit provides a robust platform for developing lithium battery charging solutions, combining efficiency, safety, and flexibility into a single module.A very simple and efficiency Lithium battery charger and monitoring system, can be designed using the LTM8061 integrated circuit, designed by Linear Technology. The LTM8061 IC is a high efficiency 32V, 2A Module standalone Lithium battery charger optimized for one and two-cell packs, with fixed float voltage options: 4.

1V, 4. 2V, 8. 2V and 8. 4V . A precondition feature trickle charges a depleted battery, and bad battery detection provides a signal and suspends charging if a battery does not respond to preconditioning. The LTM8061 can be configured to terminate charging when charge current falls to one-tenth the programmed maximum current or to use an internal timer if a time based termination scheme is desired.

When charging is terminated, the LTM8061 enters a low current standby mode. If the battery voltage drops 2. 5% from the fl oat voltage, or if a new battery is inserted into a charging system, the auto-restart feature starts a new charge cycle. To design a charger using the LTM8061 IC, you`ll need just to select the right chip and apply few equations ( just in case if you don`t want the standard configuration, for example if you want to limit the input current ).

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713