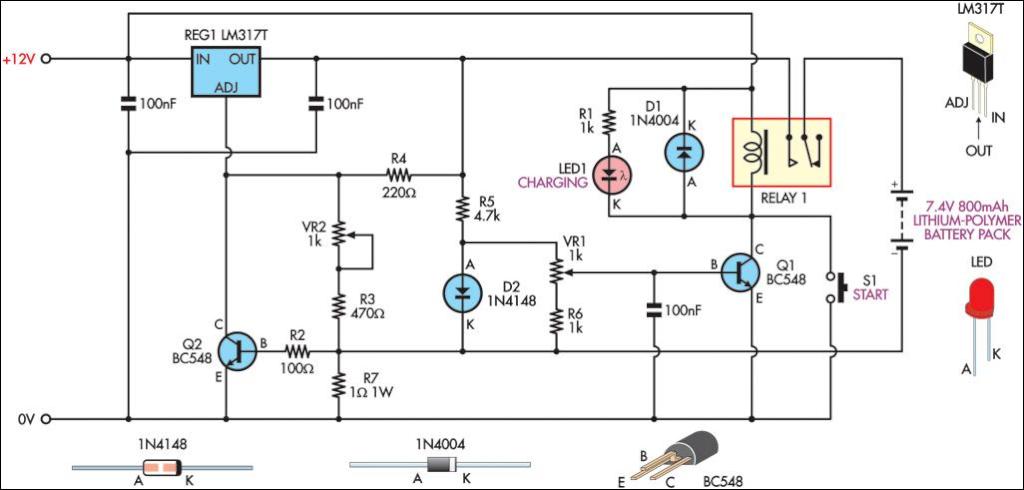

Lithium-Polymer Peak Charger

This circuit was developed to charge the Lithium-Polymer cells used in a model aircraft. Lithium-Polymer cells are incredibly lightweight compared to Nickel-Cadmium cells.

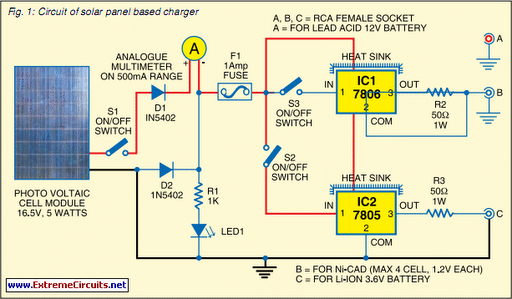

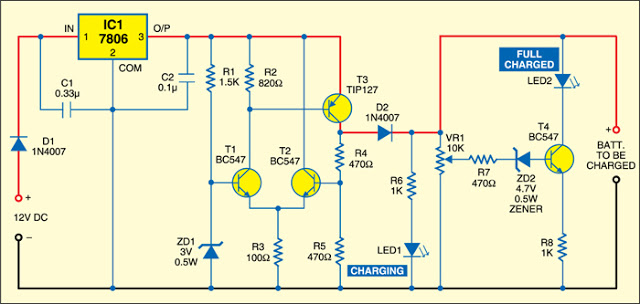

The circuit is designed to efficiently charge Lithium-Polymer (LiPo) batteries, which are commonly utilized in model aircraft due to their high energy density and lightweight characteristics. The charging circuit typically employs a dedicated LiPo battery charger IC that regulates the voltage and current to ensure safe and optimal charging of the cells.

Key components of the circuit include a microcontroller or dedicated charging IC, MOSFETs for switching, and various passive components such as resistors and capacitors to filter and stabilize the voltage levels. The charging process often follows a constant current/constant voltage (CC/CV) method, where the charger initially applies a constant current until the battery reaches a specified voltage, after which it switches to constant voltage mode to complete the charging cycle.

Safety features are critical in LiPo charging circuits due to the sensitivity of these cells to overcharging and overheating. The circuit may include temperature sensors to monitor the battery temperature and cutoff mechanisms to prevent charging beyond safe limits. Additionally, a balance charging feature may be integrated to ensure that all cells in a multi-cell configuration are charged evenly, thus prolonging the battery's lifespan and maintaining performance.

The overall design must consider the input power source, which can be a wall adapter or a battery, ensuring that the input voltage is compatible with the charging requirements of the LiPo cells. The output connections should be designed to accommodate the specific battery connector types used in model aircraft applications, ensuring secure and reliable connections during the charging process.

In summary, the circuit is a specialized charging solution that prioritizes efficiency, safety, and compatibility with Lithium-Polymer cells, making it suitable for applications in model aircraft and other lightweight electronic devices.This circuit was developed to charge the Lithium-Polymer cells used in a model aircraft. Lithium-Polymer cells are incredibly lightweight compared to Ni-c.. 🔗 External reference

The circuit is designed to efficiently charge Lithium-Polymer (LiPo) batteries, which are commonly utilized in model aircraft due to their high energy density and lightweight characteristics. The charging circuit typically employs a dedicated LiPo battery charger IC that regulates the voltage and current to ensure safe and optimal charging of the cells.

Key components of the circuit include a microcontroller or dedicated charging IC, MOSFETs for switching, and various passive components such as resistors and capacitors to filter and stabilize the voltage levels. The charging process often follows a constant current/constant voltage (CC/CV) method, where the charger initially applies a constant current until the battery reaches a specified voltage, after which it switches to constant voltage mode to complete the charging cycle.

Safety features are critical in LiPo charging circuits due to the sensitivity of these cells to overcharging and overheating. The circuit may include temperature sensors to monitor the battery temperature and cutoff mechanisms to prevent charging beyond safe limits. Additionally, a balance charging feature may be integrated to ensure that all cells in a multi-cell configuration are charged evenly, thus prolonging the battery's lifespan and maintaining performance.

The overall design must consider the input power source, which can be a wall adapter or a battery, ensuring that the input voltage is compatible with the charging requirements of the LiPo cells. The output connections should be designed to accommodate the specific battery connector types used in model aircraft applications, ensuring secure and reliable connections during the charging process.

In summary, the circuit is a specialized charging solution that prioritizes efficiency, safety, and compatibility with Lithium-Polymer cells, making it suitable for applications in model aircraft and other lightweight electronic devices.This circuit was developed to charge the Lithium-Polymer cells used in a model aircraft. Lithium-Polymer cells are incredibly lightweight compared to Ni-c.. 🔗 External reference