Microfluidics Research

A simple and high-throughput microfluidic system is presented for monitoring diffusion-based monolayer yeast cell cultures. This technique utilizes gas solubility and the elasticity of PDMS. Yeast cells are arranged in a micro-cavity array with a height of 4 µm, maintaining a monolayer during cell division. As a demonstration, this technology is applied to study budding and fission yeast cultures, allowing for single-cell resolution across multiple generations. The results indicate that the method facilitates the investigation of single yeast cell phenotypes and cell-cell communication in a high-throughput microfluidic system.

The device consists of a two-layer microfluidic structure. Layer 1 features 100 square cavities of varying side lengths (100, 125, 150, 175, 200 µm) and an additional 100 square cavities each measuring 150 µm. Layer 2 forms the main channel. Each cavity is equipped with a capillary measuring 40 µm in width, ready to connect to the main channel. The loading process of cells into the cavity is also described.

A programmed syringe pump system is proposed for controlling diffusion-based concentration in microcavities over extended periods. Fluorescein demonstrates the effects of different durations of consistent injection speeds and varying microcavity sizes on concentration control and distribution. Longer injection durations and smaller microcavities yield more consistent concentration control aligned with input signals. This system allows for precise adjustments to the microenvironment of cells over time, making it suitable for high-throughput cell stimulation or differentiation studies.

Additionally, conductive polymer gels are utilized as pressure sensor elements in microfluidic devices. These gels are created by curing a mixture of polydimethylsiloxane with carbon or metal powders on a substrate. Once integrated, they serve as piezoresistive sensors for low-pressure applications, offering a simple and rapid method applicable to various micro devices with direct current readout capabilities.

The circuit diagram for current readout includes a waveform generator as an AC power supply, with voltage measurements taken via an oscilloscope. The schematic outlines the sensing device, where an electrolyte is injected through a metal inlet, and pressure in the microfluidic channel is regulated by applied air pressure.

Lastly, microfluidics-based cellular electroporation is highlighted for its efficiency in delivering small molecules into cells. This study employs hydrodynamic focusing of fluids with different conductivities in a microfluidic chip, achieving high-throughput cell electroporation with low voltage (less than 3V) DC power supply. Simulation results indicate that a mere 1.5V input voltage can generate an electric field of approximately 1.17 kV/cm across the cell suspension flow in the focused region, resulting in a cell electropermeation efficiency of up to 70%. The experimental setup is illustrated with a schematic of the hydrodynamic focusing microelectroporation chip, capturing fluorescence images during the process.We present a simple and high-throughput microfluidic system for diffusion-based monolayer yeast cell culture monitoring. The technique takes advantage of gas solubility and elasticity of PDMS. Yeast cells are patterned into the micro-cavity array with a suitable height (4 m) that keeps the cells in monolayer during the cell division.

As a demons tration, we apply this technology to investigate budding yeast and fission yeast cultures and show that it permits single-cell resolution over many cellular generations. Our results show that the technique provides an easy way to study the phenotype of single yeast cell cycle or cell-cell communication in high-throughput microfluidic system.

Fig. 1 (a) Pattern for the2-layer microfluidic device fabrication. Layer 1: 100 square cavities with different side lengths (100, 125, 150, 175, 200 m); 100 square cavities with side lengths of 150 m. Layer 2: the mainchannel; (b) The top view and side view of the microfluidic device, Each cavity has a capillary of 40 m width ready to be connected to the mainchannel.

(c) Procession of cells loaded into the cavity 2. Diffusion-based concentration control in microcavities during long time period by programmed syringe pumps, Guangwei si, Xuejun zhu, Yangsen Kang, Chunxiong Luo*, Qi Ouyang*, Yong Chen We propose a programmed syringe pumps system for diffusion-based concentration control in microcavities. Fluorescein is used to demonstrate the influence of different duration s of unvarying injecting speed and different sizes of microcavities on the concentration control and distribution in the microcavities.

With longer duration of unvarying injecting speed and smaller size of microcavities, the concentration control of the microcavities will be more consistent with the input signal. Using this system, we can precisely control sudden as well as gradual change of the microenvironment of cells within a period from several minutes to days by re-setting parameters of the program.

This system will be useful for high-throughput cell stimulation or differentiation studies. Fig. 1. (a) t he mask of the chip (b) the microscopic pictures of fluorescein mixing results in the front, middle and end of the mixing area (c) ImageJ analysis result of fluorescein mixing in the mixing area. Fig. 2. Concentration variation of the main channel in the microcavities area: (a) the injection speed of syringe pumps to time (b) simulation of the concentration variation with time (c) with different We report on the use of conductive polymer gels as pressure sensor elements in commonly used microfluidic devices.

The polymer gels are molded on a substrate by curing a mixture of polydimethylsiloxane and carbon or metal powders. After integration into the microfluidic devices, the polymer gels act as piezoresistive sensing element for repeated use in a low pressure range.

Our method is simple, fast, and applicable to virtually any type of micro devices with a direct current readout. Figure 2. Microphotograph of a Ni-PDMS gel array which has been integrated into a microfluidic channel for pressure sensing.

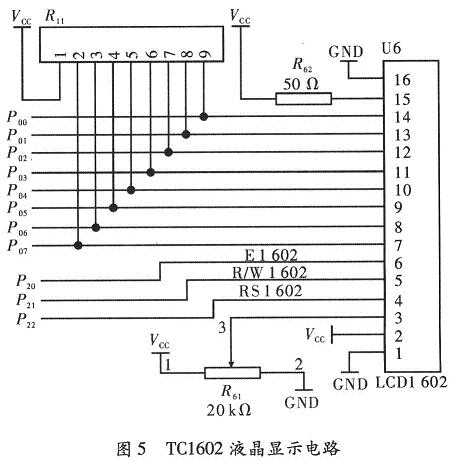

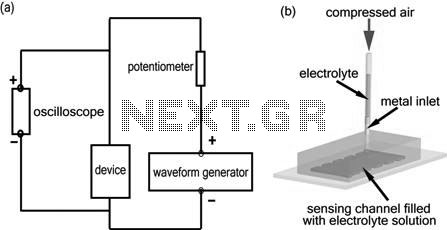

The size of the sensor unit is 30x30 m2. Figure 3. (a) Circuit diagram for the current read out of the device. A waveform generator was used as AC power supply. Voltage on the device is measured though an oscilloscope. (b) Schematic view of the sensing device: the electrolyte was injected though a metal inlet and the pressure in microfluidic channel was controlled by air pressure applied to the electrolyte. Figure 4 Variation of Ni-PDMS gel resistance versus applied pressure in compression and decompression cycles; each value under different pressure was averaged over 7 cycles.

Microfluidics-based cellular electroporation has many advantages in delivering small molecules into cells, whose applications develop very fast recently. In this study, b y using hydrodynamic focusing of the fluids with different conductivities in a microfluidic chip, high through-put cell electroporation wa s realized with low voltage (< 3V) supply of direct current (DC) power.

Simulation results showed that an input voltage of only 1. 5V could generate electric field of about 1. 17 kV cm -1 across the cell suspension flow in the squeezed area. The electropermeation of yeast cell was observed, and the efficiency reached up to 70%. Fig. 1 Schematic of the hydrodynamic focusing microelectroporation chip. Cells passing through the focusing region experience a local high density electric charge. The fluorescence image was captured during the experiment. 🔗 External reference

The device consists of a two-layer microfluidic structure. Layer 1 features 100 square cavities of varying side lengths (100, 125, 150, 175, 200 µm) and an additional 100 square cavities each measuring 150 µm. Layer 2 forms the main channel. Each cavity is equipped with a capillary measuring 40 µm in width, ready to connect to the main channel. The loading process of cells into the cavity is also described.

A programmed syringe pump system is proposed for controlling diffusion-based concentration in microcavities over extended periods. Fluorescein demonstrates the effects of different durations of consistent injection speeds and varying microcavity sizes on concentration control and distribution. Longer injection durations and smaller microcavities yield more consistent concentration control aligned with input signals. This system allows for precise adjustments to the microenvironment of cells over time, making it suitable for high-throughput cell stimulation or differentiation studies.

Additionally, conductive polymer gels are utilized as pressure sensor elements in microfluidic devices. These gels are created by curing a mixture of polydimethylsiloxane with carbon or metal powders on a substrate. Once integrated, they serve as piezoresistive sensors for low-pressure applications, offering a simple and rapid method applicable to various micro devices with direct current readout capabilities.

The circuit diagram for current readout includes a waveform generator as an AC power supply, with voltage measurements taken via an oscilloscope. The schematic outlines the sensing device, where an electrolyte is injected through a metal inlet, and pressure in the microfluidic channel is regulated by applied air pressure.

Lastly, microfluidics-based cellular electroporation is highlighted for its efficiency in delivering small molecules into cells. This study employs hydrodynamic focusing of fluids with different conductivities in a microfluidic chip, achieving high-throughput cell electroporation with low voltage (less than 3V) DC power supply. Simulation results indicate that a mere 1.5V input voltage can generate an electric field of approximately 1.17 kV/cm across the cell suspension flow in the focused region, resulting in a cell electropermeation efficiency of up to 70%. The experimental setup is illustrated with a schematic of the hydrodynamic focusing microelectroporation chip, capturing fluorescence images during the process.We present a simple and high-throughput microfluidic system for diffusion-based monolayer yeast cell culture monitoring. The technique takes advantage of gas solubility and elasticity of PDMS. Yeast cells are patterned into the micro-cavity array with a suitable height (4 m) that keeps the cells in monolayer during the cell division.

As a demons tration, we apply this technology to investigate budding yeast and fission yeast cultures and show that it permits single-cell resolution over many cellular generations. Our results show that the technique provides an easy way to study the phenotype of single yeast cell cycle or cell-cell communication in high-throughput microfluidic system.

Fig. 1 (a) Pattern for the2-layer microfluidic device fabrication. Layer 1: 100 square cavities with different side lengths (100, 125, 150, 175, 200 m); 100 square cavities with side lengths of 150 m. Layer 2: the mainchannel; (b) The top view and side view of the microfluidic device, Each cavity has a capillary of 40 m width ready to be connected to the mainchannel.

(c) Procession of cells loaded into the cavity 2. Diffusion-based concentration control in microcavities during long time period by programmed syringe pumps, Guangwei si, Xuejun zhu, Yangsen Kang, Chunxiong Luo*, Qi Ouyang*, Yong Chen We propose a programmed syringe pumps system for diffusion-based concentration control in microcavities. Fluorescein is used to demonstrate the influence of different duration s of unvarying injecting speed and different sizes of microcavities on the concentration control and distribution in the microcavities.

With longer duration of unvarying injecting speed and smaller size of microcavities, the concentration control of the microcavities will be more consistent with the input signal. Using this system, we can precisely control sudden as well as gradual change of the microenvironment of cells within a period from several minutes to days by re-setting parameters of the program.

This system will be useful for high-throughput cell stimulation or differentiation studies. Fig. 1. (a) t he mask of the chip (b) the microscopic pictures of fluorescein mixing results in the front, middle and end of the mixing area (c) ImageJ analysis result of fluorescein mixing in the mixing area. Fig. 2. Concentration variation of the main channel in the microcavities area: (a) the injection speed of syringe pumps to time (b) simulation of the concentration variation with time (c) with different We report on the use of conductive polymer gels as pressure sensor elements in commonly used microfluidic devices.

The polymer gels are molded on a substrate by curing a mixture of polydimethylsiloxane and carbon or metal powders. After integration into the microfluidic devices, the polymer gels act as piezoresistive sensing element for repeated use in a low pressure range.

Our method is simple, fast, and applicable to virtually any type of micro devices with a direct current readout. Figure 2. Microphotograph of a Ni-PDMS gel array which has been integrated into a microfluidic channel for pressure sensing.

The size of the sensor unit is 30x30 m2. Figure 3. (a) Circuit diagram for the current read out of the device. A waveform generator was used as AC power supply. Voltage on the device is measured though an oscilloscope. (b) Schematic view of the sensing device: the electrolyte was injected though a metal inlet and the pressure in microfluidic channel was controlled by air pressure applied to the electrolyte. Figure 4 Variation of Ni-PDMS gel resistance versus applied pressure in compression and decompression cycles; each value under different pressure was averaged over 7 cycles.

Microfluidics-based cellular electroporation has many advantages in delivering small molecules into cells, whose applications develop very fast recently. In this study, b y using hydrodynamic focusing of the fluids with different conductivities in a microfluidic chip, high through-put cell electroporation wa s realized with low voltage (< 3V) supply of direct current (DC) power.

Simulation results showed that an input voltage of only 1. 5V could generate electric field of about 1. 17 kV cm -1 across the cell suspension flow in the squeezed area. The electropermeation of yeast cell was observed, and the efficiency reached up to 70%. Fig. 1 Schematic of the hydrodynamic focusing microelectroporation chip. Cells passing through the focusing region experience a local high density electric charge. The fluorescence image was captured during the experiment. 🔗 External reference