PIC12F629 based IR decoder

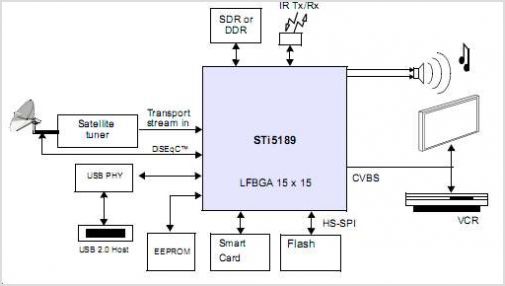

The IR Widget captures infrared signals used by remote controls and can determine the carrier frequency while demodulating it in either the digital or analog domain. The captured data can be utilized to reproduce or recognize the signal. The hardware is designed to be simple and cost-effective. A PIC12F629 microcontroller was used for the prototype, although any PIC that employs the 12 or 14-bit instruction set could be suitable. The typical low-cost approach to IR capture involves connecting an IR detector or demodulator module to a serial or parallel port. This method functions adequately when the CPU is dedicated to managing the port but becomes inefficient within a preemptive multitasking operating system, as the OS continually services hardware interrupts even during idle states, leading to constant interruptions in IR capture. High CPU usage occurs when polling is implemented. Utilizing the hardware interrupt capability of the port can significantly reduce CPU load; however, interrupt latency may result in inaccuracies. As parallel and serial ports are becoming less prevalent, USB adapters are not compatible with these simple circuits. The IR Widget addresses these challenges by employing a microcontroller for precise timing and transmitting data to the PC via standard asynchronous serial communication. This enables the operating system to manage the serial port with its usual drivers and facilitates the use of USB-to-serial converters. The circuit is powered through the serial port, and the PIC directly drives the serial RX data line. An infrared detector module is incorporated to enable the PIC to detect every infrared pulse at close range, ensuring maximum detail and accuracy. An infrared demodulator module may also be utilized for long-range reception with reduced detail. Infrared remotes generally operate at a carrier frequency of 30 to 60 kHz, with the carrier being fully on and off. Carrier on times typically range from 400 microseconds to several milliseconds, while off times can vary from 400 microseconds to over 100 milliseconds. To accurately measure the frequency of a pulsed carrier, a short gate time is essential; a standard frequency counter with a one-second gate will not yield accurate readings. Although the frequency can be derived from the period of one cycle, this necessitates high-resolution measurements for precision. The IR Widget counts the number of infrared pulses occurring within a 100-microsecond window, transmitting the count to the PC at 115200 bps, with this process repeating every 100 microseconds. To calculate the carrier frequency, the received data is analyzed for the highest count. Provided there are pulses with a duration of 200 microseconds or longer, samples will be obtained from periods where the carrier was continuously on during the sampling period, resulting in the highest count or one less than the highest count. The total of these periods is used to compute the carrier frequency with reasonable accuracy. Once the carrier frequency is established, periods with lower counts can be assessed to determine the duration of the carrier during those intervals. A Microsoft Windows program is utilized to convert the data collected from the IR Widget into a graphical representation of the infrared signal, resembling an oscilloscope or logic analyzer. The display illustrates the timing of each carrier on and off period, along with the pulse counts during the carrier on periods. Each capture is also recorded in a text file. The infrared detector module described for the capture mode has a very short range, requiring the remote to be within a few inches of the detector. While this is adequate for research purposes, it is unsuitable for remote control applications. Devices controlled by infrared remotes typically employ infrared demodulator modules, which are tuned to specific carrier frequencies and can operate at ranges of 20 feet or more. The IR Widget can support such modules and includes code for measuring their operational time.

The IR Widget circuit consists of several key components that work together to achieve effective infrared signal capture and processing. The main component is the PIC12F629 microcontroller, which serves as the heart of the system. This microcontroller is programmed to handle the timing and data processing tasks necessary for accurate signal analysis. The infrared detector module is connected to one of the microcontroller's input pins, allowing it to detect incoming infrared pulses. The module is sensitive enough to capture signals at close range, making it ideal for detailed analysis.

The microcontroller's firmware is designed to count the number of detected pulses within a defined 100-microsecond interval. This counting process is achieved through the use of timers and interrupts, allowing the microcontroller to operate efficiently without significant CPU load. The captured pulse count is then transmitted to a connected PC via a serial interface at a baud rate of 115200 bps. This high-speed communication ensures that data is relayed in real-time, enabling quick analysis and visualization.

The IR Widget's design also incorporates a power management feature, drawing power directly from the serial port. This eliminates the need for an external power supply, enhancing portability and ease of use. The use of standard asynchronous serial communication allows compatibility with a wide range of devices, including USB-to-serial converters, which are essential as traditional serial and parallel ports become less common.

For long-range applications, the IR Widget can be paired with an infrared demodulator module. This module is tuned to specific carrier frequencies, allowing it to filter out unwanted signals and focus on the desired infrared communication. The integration of this module into the IR Widget expands its functionality, making it suitable for various remote control applications.

The accompanying software provides a user-friendly interface for visualizing the captured infrared signals. The graphical representation allows users to observe the timing and duration of carrier on and off periods, as well as the pulse counts. This capability is invaluable for troubleshooting remote control systems or developing new infrared communication protocols.

In summary, the IR Widget represents a versatile and effective solution for capturing and analyzing infrared signals from remote controls. Its combination of a microcontroller, infrared detection modules, and software visualization tools makes it a powerful tool for both research and practical applications in the field of infrared communication.The IR Widget captures the infrared signals used by remote controls. It is able to determine the carrier frequency and demodulate the carrier in the digital or analog domain. The captured information can be used to reproduce or recognize the signal. The hardware is designed to be as simple and low cost as possible. A PIC12F629 was used for the pro totype, but almost any PIC that uses the 12 or 14 bit instruction set could be used. The usual approach to low cost IR capture typically consists of an IR detector or demodulator module connected to a serial or parallel port. This can work quite well when the CPU is dedicated to servicing the port. It does not work very well within a preemptive multitasking operating system. The OS is constantly servicing hardware interrupts even when the system is idle, so the IR capture is constantly interrupted.

CPU usage is high when polling is used. Using the hardware interrupt capability of the port can greatly reduce CPU load, but interrupt latency may cause inaccurate results. Parallel and serial ports are becoming less common, and USB adapters do not work for these simple circuits.

The IR Widget solves these problems by using a microcontroller to do precise timing and send the data to the PC using ordinary asynchronous serial transmission. This allows the OS to service the serial port with it ’s normal drivers and allows the use of USB to serial converters.

The circuit is powered from the serial port and the PIC directly drive the serial rx data line. An infrared detector module is used to allow the PIC to see every infrared pulse at close range. This allows for greatest detail and accuracy. An infrared demodulator module can also be used to allow for long range reception with less detail. Infrared remotes typically use a carrier frequency of 30 to 60 kHz. The carrier is keyed full on and full off. Carrier on times typically range from 400 microseconds to several milliseconds. Carrier off times typically range from 400 microseconds to more than 100 milliseconds. To measure the frequency of a pulsed carrier, a short gate time is required. An ordinary frequency counter with 1 second gate will not give an accurate reading. The frequency could be determined from the period of one cycle, but this would require a rather high resolution measurement for a precise reading. The IR Widget counts the number of infrared pulses that occur within a 100 microsecond period. The count is sent to the PC at 115200 bps. This repeats every 100 microseconds. To calculate the carrier frequency, the received data is scanned for the highest count. As long as there are pulses of 200 microseconds or greater duration, there will be samples from periods where the carrier was on for the entire sample period.

These periods will have the highest count or one less than the highest count. The sum of all these periods is used to calculate the carrier frequency with reasonable precision. Once the carrier frequency is know, the periods with lesser counts can be evaluated to determine the duration of the carrier during those periods. A Microsoft Windows program is used to transform the data gather from the IR Widget in to a graphical representation of the infrared signal.

The display is similar to an oscilloscope or logic analyzer. The time of each carrier on and off period is shown as well as the count of pulses during the carrier on periods. Each capture is also written to a text file. The infrared detector module for the previously described capture mode has a very short range. The remote must be within a few inches of the detector module. This is fine for research, but not suitable for remote control. Devices that are controlled by infrared remotes typically use an infrared demodulator modules. These modules are tuned to a specific carrier frequency and have a range of 20 feet or more. The IR Widget can accommodate such a module and has code for measuring the time 🔗 External reference

The IR Widget circuit consists of several key components that work together to achieve effective infrared signal capture and processing. The main component is the PIC12F629 microcontroller, which serves as the heart of the system. This microcontroller is programmed to handle the timing and data processing tasks necessary for accurate signal analysis. The infrared detector module is connected to one of the microcontroller's input pins, allowing it to detect incoming infrared pulses. The module is sensitive enough to capture signals at close range, making it ideal for detailed analysis.

The microcontroller's firmware is designed to count the number of detected pulses within a defined 100-microsecond interval. This counting process is achieved through the use of timers and interrupts, allowing the microcontroller to operate efficiently without significant CPU load. The captured pulse count is then transmitted to a connected PC via a serial interface at a baud rate of 115200 bps. This high-speed communication ensures that data is relayed in real-time, enabling quick analysis and visualization.

The IR Widget's design also incorporates a power management feature, drawing power directly from the serial port. This eliminates the need for an external power supply, enhancing portability and ease of use. The use of standard asynchronous serial communication allows compatibility with a wide range of devices, including USB-to-serial converters, which are essential as traditional serial and parallel ports become less common.

For long-range applications, the IR Widget can be paired with an infrared demodulator module. This module is tuned to specific carrier frequencies, allowing it to filter out unwanted signals and focus on the desired infrared communication. The integration of this module into the IR Widget expands its functionality, making it suitable for various remote control applications.

The accompanying software provides a user-friendly interface for visualizing the captured infrared signals. The graphical representation allows users to observe the timing and duration of carrier on and off periods, as well as the pulse counts. This capability is invaluable for troubleshooting remote control systems or developing new infrared communication protocols.

In summary, the IR Widget represents a versatile and effective solution for capturing and analyzing infrared signals from remote controls. Its combination of a microcontroller, infrared detection modules, and software visualization tools makes it a powerful tool for both research and practical applications in the field of infrared communication.The IR Widget captures the infrared signals used by remote controls. It is able to determine the carrier frequency and demodulate the carrier in the digital or analog domain. The captured information can be used to reproduce or recognize the signal. The hardware is designed to be as simple and low cost as possible. A PIC12F629 was used for the pro totype, but almost any PIC that uses the 12 or 14 bit instruction set could be used. The usual approach to low cost IR capture typically consists of an IR detector or demodulator module connected to a serial or parallel port. This can work quite well when the CPU is dedicated to servicing the port. It does not work very well within a preemptive multitasking operating system. The OS is constantly servicing hardware interrupts even when the system is idle, so the IR capture is constantly interrupted.

CPU usage is high when polling is used. Using the hardware interrupt capability of the port can greatly reduce CPU load, but interrupt latency may cause inaccurate results. Parallel and serial ports are becoming less common, and USB adapters do not work for these simple circuits.

The IR Widget solves these problems by using a microcontroller to do precise timing and send the data to the PC using ordinary asynchronous serial transmission. This allows the OS to service the serial port with it ’s normal drivers and allows the use of USB to serial converters.

The circuit is powered from the serial port and the PIC directly drive the serial rx data line. An infrared detector module is used to allow the PIC to see every infrared pulse at close range. This allows for greatest detail and accuracy. An infrared demodulator module can also be used to allow for long range reception with less detail. Infrared remotes typically use a carrier frequency of 30 to 60 kHz. The carrier is keyed full on and full off. Carrier on times typically range from 400 microseconds to several milliseconds. Carrier off times typically range from 400 microseconds to more than 100 milliseconds. To measure the frequency of a pulsed carrier, a short gate time is required. An ordinary frequency counter with 1 second gate will not give an accurate reading. The frequency could be determined from the period of one cycle, but this would require a rather high resolution measurement for a precise reading. The IR Widget counts the number of infrared pulses that occur within a 100 microsecond period. The count is sent to the PC at 115200 bps. This repeats every 100 microseconds. To calculate the carrier frequency, the received data is scanned for the highest count. As long as there are pulses of 200 microseconds or greater duration, there will be samples from periods where the carrier was on for the entire sample period.

These periods will have the highest count or one less than the highest count. The sum of all these periods is used to calculate the carrier frequency with reasonable precision. Once the carrier frequency is know, the periods with lesser counts can be evaluated to determine the duration of the carrier during those periods. A Microsoft Windows program is used to transform the data gather from the IR Widget in to a graphical representation of the infrared signal.

The display is similar to an oscilloscope or logic analyzer. The time of each carrier on and off period is shown as well as the count of pulses during the carrier on periods. Each capture is also written to a text file. The infrared detector module for the previously described capture mode has a very short range. The remote must be within a few inches of the detector module. This is fine for research, but not suitable for remote control. Devices that are controlled by infrared remotes typically use an infrared demodulator modules. These modules are tuned to a specific carrier frequency and have a range of 20 feet or more. The IR Widget can accommodate such a module and has code for measuring the time 🔗 External reference