PID PROJECT

To manufacture large quantities of products, a manufacturing system or process is essential. This process can be categorized as either open-loop or closed-loop. In an open-loop system, variables are controlled manually, whereas in a closed-loop system, they are controlled automatically. Most industrial applications favor closed-loop systems. The goal of a closed-loop system is to maintain one or more controlled variables at a desired set point, which represents the target measurement. Common examples of controllers that automatically adjust variables to maintain set points include household thermostats and automotive cruise control systems. The controlled variable is the actual variable being monitored, which is tracked by a measurement device that transmits a feedback signal to the error detector. This error detector compares the feedback signal with the set point and generates an error signal sent to the controller. The controller then determines the necessary actions to align the controlled variable with the set point and sends a signal to the actuator, which physically modifies the manipulated variable. The manipulated variable is the energy adjusted by the actuator, and its modification results in the controlled variable reaching the desired set point. Various types of closed-loop systems exist, categorized by the processes they control. In industrial settings, PID controllers are prevalent. PID stands for Proportional (Gain), Integral (Reset), and Derivative (Rate). These terms define how quickly the controller alters the output signal. Proportional control is the simplest feedback control method and is the most commonly implemented control loop. A proportional controller multiplies the error signal by a constant before sending it to the actuator. Integral control adds long-term accuracy to the control loop and is usually combined with proportional control. Derivative control relates the controller output to the rate of change of the measurement or error over time. The focus of this project is on Proportional Control, also known as Gain control. The controller utilizes the error signal to determine how to adjust the gain to the actuator, with the error signal being the difference between the set point and the measurement. The EET 231 Closed-loop Temperature Controller was designed to maintain a thermistor at a constant temperature using a microprocessor as the controller. It features a GUI interface created in Visual Basic 6 to control the set point and monitor the output signal. The actuator in this system is an incandescent light bulb, which generates heat to warm the thermistor. The set point is defined in the Visual Basic program, and the thermistor measures the temperature while the computer adjusts the current to the light bulb to maintain the set point. The lamp is pulsed to modify the thermistor's value. The thermistor is part of a bridge circuit connected to an instrumentation amplifier linked to an analog-to-digital (A to D) converter. Several electronic circuits were developed and integrated with the Visual Basic program to complete the system. The Visual Basic program manages the ports of the 8255 I/O chip within the microprocessor. An 8086 interface board connects the microprocessor to the closed-loop control circuitry, serving as the system's starting point. Once the computer determines how to adjust the manipulated variable, the D to A converter is the first step. A schematic of a D to A converter is presented in Figure 1, while Figure 2 illustrates the output signal. After the sawtooth signal exits the comparator, it enters another D to A converter that outputs to an 8-bit counter. Figure 1 also depicts a schematic of a 4-bit counter. The current supplied to the lamp is adjusted based on variations in the thermistor signal. The thermistor is a component of the bridge circuit. The Visual Basic interface enables the user to modify the set point and visually track the temperature on a graph. Screenshots of the Visual Basic interface under various conditions are provided, showing a set point of 74, with the graph displaying output tracking the set point as it is adjusted. The Power To Lamp indicator reveals the power being delivered to the actuator at any moment. The system performed effectively in maintaining proximity to the set point, although it was never fully reached due to ambient temperature disturbances affecting the output. Incorporating integral and derivative controls could address this issue. Additionally, introducing a cooling fan to the system may enhance the precision of the set point range, as the lamp's cooling rate was insufficient during significant set point changes. Overall, the closed-loop temperature controller exemplifies the P in PID control systems.

The closed-loop temperature control system described features a comprehensive architecture integrating various electronic components and control strategies. The primary components include the microprocessor, which serves as the central processing unit, the thermistor for temperature sensing, and the incandescent light bulb as the actuator. The system operates by continuously monitoring the temperature via the thermistor, which is part of a bridge circuit that converts the temperature reading into a voltage signal. This signal is amplified by an instrumentation amplifier before being digitized by the A to D converter for processing by the microprocessor.

The control algorithm implemented in the microprocessor utilizes a proportional control strategy. The error signal, derived from the difference between the desired set point and the current temperature reading, is calculated and used to determine the necessary adjustments to the actuator. This adjustment is communicated through a D to A converter, which translates the digital control signal back into an analog signal to modulate the power supplied to the light bulb. The system's feedback loop ensures that any deviations from the set point are corrected by dynamically adjusting the power output to the lamp.

The user interface, developed in Visual Basic 6, provides an intuitive platform for setting the desired temperature and monitoring system performance. It displays real-time data, including the current temperature, set point, and power output, allowing for effective user interaction and system oversight. The graphical representation of temperature tracking against the set point offers valuable insights into system performance and stability.

In summary, this closed-loop temperature control system exemplifies the practical application of PID control principles, specifically focusing on proportional control. The integration of various electronic components, coupled with a user-friendly interface, facilitates efficient temperature management, making it suitable for a range of industrial and laboratory applications. Further enhancements, such as the implementation of integral and derivative control strategies and the addition of cooling mechanisms, could improve system performance and accuracy in maintaining the desired temperature set points.In order to manufacture large quantities of anything, there needs to be a manufacturing system or process in place. The manufacturing process can be open loop or closed-loop. In an open-loop system, variables are controlled manually. In a closed-loop system, variables are controlled automatically. The majority of applications in industry require a closed-loop system. The objective of a closed-loop system is to keep one or more controlled variables equal to the desired set point. The set point is where you would like the measurement to be. The thermostat in your house and the cruise control in your car are common examples of how controllers are used to automatically adjust some variable to hold the measurement at the set point.

The controlled variable is the actual variable being monitored and maintained. It is monitored by a measurement device that sends a feedback signal to the error detector. The error detector compares the feedback signal to the set point and creates an error signal that is sent to the controller. The controller determines what action to take in order to match the set point and then sends a signal to the actuator that physically adjusts the manipulated variable.

The manipulated variable is the energy that is altered by the actuator. The adjustment of the manipulated variable causes the controlled variable to change to the desired set point. There are many different types of closed-loop systems and they are generally defined by the kind of process or system they control.

In industry, PID controllers are common closed-loop controllers. PID stands for Proportional (Gain), Integral (Reset), and Derivative (Rate). The terms Gain, Reset, and Rate are functions that determine how fast the controller will change the output signal. Proportional control is the easiest feedback control to implement, and simple proportional control is probably the most common kind of control loop.

A proportional controller is just the error signal multiplied by a constant and fed out to the actuator. Integral control is used to add long-term precision to a control loop. It is almost always used in conjunction with proportional control. With derivative control, the controller output is proportional to the rate of change of the measurement or error.

The controller output is calculated by the rate of change of the measurement with time. Our project focuses on the most common control - Proportional Control. This type of control is also known as Gain control. The Controller uses the Error signal to decide how it will adjust the gain to the actuator. The Error signal is defined as the difference between set point and measurement. The EET 231 Closed-loop Temperature Controller was designed to keep a thermistor at a constant temperature using a microprocessor as the controller. It uses a GUI interface written in Visual Basic 6 to control the set point and view the output signal.

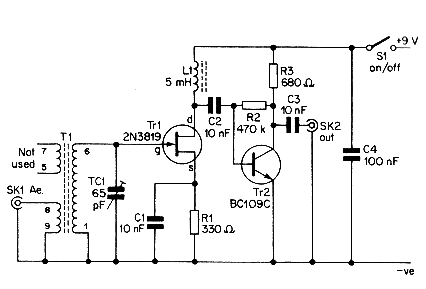

The actuator in this system is an incandescent light bulb. The heat from the light bulb is used to warm the thermistor. The set point is set in the Visual Basic program. The thermistor senses the temperature and the computer adjusts the current flow to the light bulb to maintain the set point value. The lamp is pulsed to change the thermistor value. The thermistor is part of a bridge circuit that is connected to an Instrumentation Amplifier that is connected to an Analog to Digital (A to D) converter.

Several combined electronic circuits were constructed and used in conjunction with the Visual Basic Program to complete the system. The next sections give a description of the entire system. The Visual Basic program used for this system controls the ports of the 8255 I/O chip within the microprocessor.

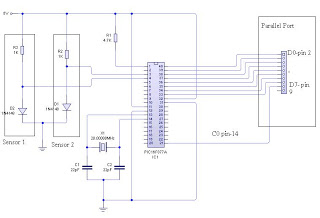

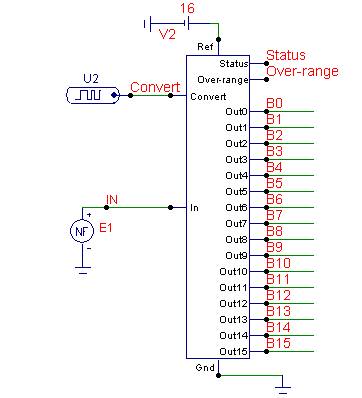

An 8086 interface board connects the microprocessor to the closed-loop control circuitry. This could be thought of as the starting point of the system. Once the computer decides how it will adjust the manipulated variable, the D to A converter is the first stop. Figure 1 shows a schematic of a D to A converter and Figure 2 shows the output signal. Once the saw tooth signal leaves the comparator it enters another D to A converter that outputs to an 8- Bit Counter.

Figure 1 shows a schematic of a 4-Bit counter. Current to the lamp is increased or decreased as the signal from the thermistor varies. The circuit that contains the thermistor is the bridge circuit. The thermistor is actually a leg of the bridge. The Visual Basic interface allows the user to adjust the set point. It also plots the temperature on a graph. The following screenshots show the Visual Basic interface during various conditions. In this screenshot, the set point is 74. The graph shows the output tracking the set point as the set point is adjusted. The Power To Lamp indicator shows the power being sent to the actuator at any given time. This system did a good job of tracking close to the set point, though the set point was never quite reached. The ambient temperature of the room caused a disturbance that made it hard for the output to reach the set point.

The addition of Integral and Derivative controls would solve this issue. Another possible improvement would be to add a cooling fan to the system. The lamp in the circuit could not cool down fast enough during broad set point changes. A cooling fan could be added to the system to improve the set point range precision. Overall, the closed-loop temperature controller is a good representation of the P` in PID. 🔗 External reference

The closed-loop temperature control system described features a comprehensive architecture integrating various electronic components and control strategies. The primary components include the microprocessor, which serves as the central processing unit, the thermistor for temperature sensing, and the incandescent light bulb as the actuator. The system operates by continuously monitoring the temperature via the thermistor, which is part of a bridge circuit that converts the temperature reading into a voltage signal. This signal is amplified by an instrumentation amplifier before being digitized by the A to D converter for processing by the microprocessor.

The control algorithm implemented in the microprocessor utilizes a proportional control strategy. The error signal, derived from the difference between the desired set point and the current temperature reading, is calculated and used to determine the necessary adjustments to the actuator. This adjustment is communicated through a D to A converter, which translates the digital control signal back into an analog signal to modulate the power supplied to the light bulb. The system's feedback loop ensures that any deviations from the set point are corrected by dynamically adjusting the power output to the lamp.

The user interface, developed in Visual Basic 6, provides an intuitive platform for setting the desired temperature and monitoring system performance. It displays real-time data, including the current temperature, set point, and power output, allowing for effective user interaction and system oversight. The graphical representation of temperature tracking against the set point offers valuable insights into system performance and stability.

In summary, this closed-loop temperature control system exemplifies the practical application of PID control principles, specifically focusing on proportional control. The integration of various electronic components, coupled with a user-friendly interface, facilitates efficient temperature management, making it suitable for a range of industrial and laboratory applications. Further enhancements, such as the implementation of integral and derivative control strategies and the addition of cooling mechanisms, could improve system performance and accuracy in maintaining the desired temperature set points.In order to manufacture large quantities of anything, there needs to be a manufacturing system or process in place. The manufacturing process can be open loop or closed-loop. In an open-loop system, variables are controlled manually. In a closed-loop system, variables are controlled automatically. The majority of applications in industry require a closed-loop system. The objective of a closed-loop system is to keep one or more controlled variables equal to the desired set point. The set point is where you would like the measurement to be. The thermostat in your house and the cruise control in your car are common examples of how controllers are used to automatically adjust some variable to hold the measurement at the set point.

The controlled variable is the actual variable being monitored and maintained. It is monitored by a measurement device that sends a feedback signal to the error detector. The error detector compares the feedback signal to the set point and creates an error signal that is sent to the controller. The controller determines what action to take in order to match the set point and then sends a signal to the actuator that physically adjusts the manipulated variable.

The manipulated variable is the energy that is altered by the actuator. The adjustment of the manipulated variable causes the controlled variable to change to the desired set point. There are many different types of closed-loop systems and they are generally defined by the kind of process or system they control.

In industry, PID controllers are common closed-loop controllers. PID stands for Proportional (Gain), Integral (Reset), and Derivative (Rate). The terms Gain, Reset, and Rate are functions that determine how fast the controller will change the output signal. Proportional control is the easiest feedback control to implement, and simple proportional control is probably the most common kind of control loop.

A proportional controller is just the error signal multiplied by a constant and fed out to the actuator. Integral control is used to add long-term precision to a control loop. It is almost always used in conjunction with proportional control. With derivative control, the controller output is proportional to the rate of change of the measurement or error.

The controller output is calculated by the rate of change of the measurement with time. Our project focuses on the most common control - Proportional Control. This type of control is also known as Gain control. The Controller uses the Error signal to decide how it will adjust the gain to the actuator. The Error signal is defined as the difference between set point and measurement. The EET 231 Closed-loop Temperature Controller was designed to keep a thermistor at a constant temperature using a microprocessor as the controller. It uses a GUI interface written in Visual Basic 6 to control the set point and view the output signal.

The actuator in this system is an incandescent light bulb. The heat from the light bulb is used to warm the thermistor. The set point is set in the Visual Basic program. The thermistor senses the temperature and the computer adjusts the current flow to the light bulb to maintain the set point value. The lamp is pulsed to change the thermistor value. The thermistor is part of a bridge circuit that is connected to an Instrumentation Amplifier that is connected to an Analog to Digital (A to D) converter.

Several combined electronic circuits were constructed and used in conjunction with the Visual Basic Program to complete the system. The next sections give a description of the entire system. The Visual Basic program used for this system controls the ports of the 8255 I/O chip within the microprocessor.

An 8086 interface board connects the microprocessor to the closed-loop control circuitry. This could be thought of as the starting point of the system. Once the computer decides how it will adjust the manipulated variable, the D to A converter is the first stop. Figure 1 shows a schematic of a D to A converter and Figure 2 shows the output signal. Once the saw tooth signal leaves the comparator it enters another D to A converter that outputs to an 8- Bit Counter.

Figure 1 shows a schematic of a 4-Bit counter. Current to the lamp is increased or decreased as the signal from the thermistor varies. The circuit that contains the thermistor is the bridge circuit. The thermistor is actually a leg of the bridge. The Visual Basic interface allows the user to adjust the set point. It also plots the temperature on a graph. The following screenshots show the Visual Basic interface during various conditions. In this screenshot, the set point is 74. The graph shows the output tracking the set point as the set point is adjusted. The Power To Lamp indicator shows the power being sent to the actuator at any given time. This system did a good job of tracking close to the set point, though the set point was never quite reached. The ambient temperature of the room caused a disturbance that made it hard for the output to reach the set point.

The addition of Integral and Derivative controls would solve this issue. Another possible improvement would be to add a cooling fan to the system. The lamp in the circuit could not cool down fast enough during broad set point changes. A cooling fan could be added to the system to improve the set point range precision. Overall, the closed-loop temperature controller is a good representation of the P` in PID. 🔗 External reference