Power Supply Unit

This article provides a comprehensive overview of the methodology used for testing power supplies (PSUs) in three main sections. The first section outlines the PSU parameters that are evaluated and specifies the testing conditions. The second section defines commonly used marketing terms by PSU manufacturers. The third section details the design and operation of the PSU testbed. The primary objective of the PSU tests is to evaluate performance across various load conditions, reaching up to maximum capacity. Many reviewers traditionally utilized standard PCs for testing, which posed two significant challenges: lack of control over the power consumption of the PC and difficulty in loading high-wattage PSUs. This issue is particularly relevant today as manufacturers strive to achieve higher wattage ratings, often exceeding the requirements of typical PCs. While some may argue against testing PSUs at higher loads if typical PCs do not require more than 500W, it remains essential to assess high-wattage PSUs across their entire load range. An adjustable load with programmable control is employed in the lab for PSU testing. The testbed utilizes the inherent characteristics of metal-oxide-semiconductor field-effect transistors (MOSFETs), where a MOSFET regulates current flow in the drain-source circuit based on gate voltage. A simple schematic of a MOSFET-based current regulator illustrates that connecting the circuit to a PSU with an output voltage of +V and adjusting the variable resistor R1 alters the gate voltage of the transistor VT1, thereby changing the current I from zero to maximum, as determined by the characteristics of the transistor and/or the tested PSU. However, this circuit has limitations. As the transistor heats up, its characteristics change, resulting in a variation in current I even when the gate control voltage remains constant. To address this, a second resistor R2 and an operational amplifier DA1 are incorporated into the circuit. When the transistor is active, current I flows through the drain-source circuit and resistor R2, producing a voltage U = R2*I, according to Ohm's law. This voltage is fed into the inverting input of the operational amplifier DA1, while the non-inverting input receives the control voltage U1 from the variable resistor R1. The operational amplifier functions to maintain equal voltage at both inputs by adjusting its output voltage, which in turn regulates the gate voltage of the MOSFET and the current flowing through it. For instance, if R2 is set to 1 Ohm and a voltage of 1V is applied to R1, the operational amplifier adjusts its output to ensure that the voltage drop across R2 is also 1V, resulting in a current I of 1A. If R1 is set to 2V, the current I will adjust to 2A, and so forth. Should the current I and the voltage across R2 change due to the transistor heating, the operational amplifier will promptly adjust its output to restore balance. This configuration provides a highly controllable load, allowing for smooth current adjustments from zero to maximum with minimal effort. It is also compact, offering a more manageable solution compared to bulky low-resistance resistor setups connected to the PSU. The maximum power dissipation across the transistor is determined by its thermal resistance, the maximum allowable die temperature, and the temperature of the heatsink used. The testbed incorporates International Rectifier IRFP264N transistors, which are suitable for this application.

The PSU testing methodology described utilizes a sophisticated approach to ensure accurate and reliable results. The adjustable load with programmable control allows for precise manipulation of current, which is crucial for evaluating the performance of PSUs under varying conditions. The incorporation of MOSFETs in the design enhances the efficiency of current regulation, enabling a wide range of testing scenarios that can simulate real-world usage. The operational amplifier's feedback mechanism serves to maintain stability in the circuit, compensating for any thermal variations that may affect the output. This level of control is particularly important in high-wattage applications where even small fluctuations can impact performance metrics. Additionally, the use of high-quality components such as the IRFP264N transistors ensures that the testbed can handle significant power levels while maintaining safety and reliability. Overall, the detailed methodology and design considerations outlined in this article provide a robust framework for testing power supplies, contributing to the development of high-performance electronic devices.This article provides a detailed description of our methodology for testing power supplies in three major parts. The first one lists PSU parameters we check out and specifies the test conditions. In the second section you`ll find terms often voiced by PSU manufacturers for marketing purposes and their definitions.

The third part will be most inter esting for people who`d like to know how our PSU testbed is designed and operates. In our PSU tests our main task is to check it out at different loads, up to the maximum one. Many reviewers used to employ an ordinary PC for that purpose, installing the tested PSU into it. This method had two drawbacks: you had no control over the amount of power consumed by the PC, and it was hard to load a really high-wattage PSU. The second problem is especially crucial today when the PSU manufacturers have started a race for reaching as high a wattage rating as possible, and the capabilities of their products have by far exceeded the demands of a typical PC.

Of course, one may argue that there`s no point in testing PSUs at higher loads if no real PC needs more than 500W, but it would be odd not to check out a high-wattage PSU through its entire load range if we begin to test it at all. We use an adjustable load with programmable control to test PSUs in our labs. The testbed is based on the well-known feature of metal-oxide-semiconductor field-effect transistors (MOSFETs): a MOSFET limits the current flowing in the drain-source circuit depending on the voltage in the gate.

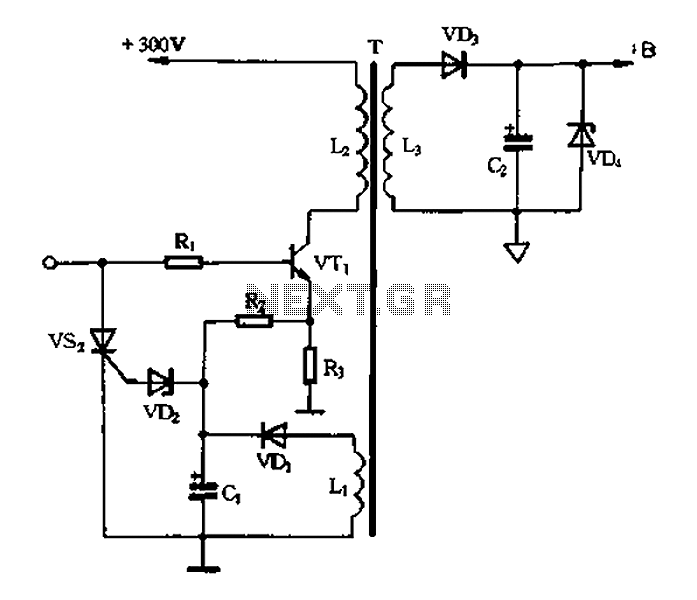

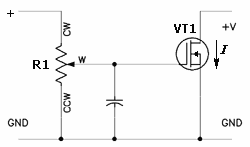

Above you can see a simple schematic of a MOSFET-based current regulator: connecting the circuit to a PSU with an output voltage of +V and turning the lever of the variable resistor R1 we are changing the voltage on the gate of the transistor VT1 thus changing the current I that flows through it from zero to maximum (determined by the characteristics of the transistor and/or tested PSU). This circuit is not perfect, though. When the transistor heats up, its characteristics change somewhat and the current I changes, too, although the control voltage on the gate remains the same.

To solve the problem, we need to add a second resistor R2 and an operation amplifier DA1 into the circuit: When the transistor is open, the current I flows through its drain-source circuit and through the resistor R2. The voltage on the latter equals U = R2*I, according to Ohm`s law. This voltage goes to the inverting input of the operation amplifier DA1. The non-inverting input of the same opamp receives the control voltage U1 from the variable resistor R1.

The opamp has such properties that it tries to maintain the same voltage on both its inputs by changing its output voltage, which in our circuit goes to the MOSFET`s gate and regulates the current flowing through it. Suppose the resistance R2 equals 1 Ohm, and we`ve set a voltage of 1V on the resistor R1. Then the opamp will change its output voltage in such a way that the voltage drop on the R2 is 1V, too.

The current I now equals 1V / 1Ohm = 1A. If we set a voltage of 2V on the R1, the opamp will react by setting the current I at 2A, etc. If the current I and, accordingly, the voltage on the resistor R2 changes due to the heating-up of the transistor, the opamp will immediately adjust its output voltage to bring them back. Thus, we have a perfectly controllable load that allows to smoothly change the current from zero to maximum with a turn of a lever.

It maintains the value you set automatically for as long as you wish. It is also compact, being much easier to handle than a clumsy set of low-resistance resistors connected in groups to the tested PSU. The maximum amount of power dissipated on the transistor is determined by its thermal resistance, the maximum allowable die temperature, and the temperature of the heatsink it is installed on.

Our testbed employs International Rectifier IRFP264N transistors (a 168KB. PDF file ) with an allo 🔗 External reference

The PSU testing methodology described utilizes a sophisticated approach to ensure accurate and reliable results. The adjustable load with programmable control allows for precise manipulation of current, which is crucial for evaluating the performance of PSUs under varying conditions. The incorporation of MOSFETs in the design enhances the efficiency of current regulation, enabling a wide range of testing scenarios that can simulate real-world usage. The operational amplifier's feedback mechanism serves to maintain stability in the circuit, compensating for any thermal variations that may affect the output. This level of control is particularly important in high-wattage applications where even small fluctuations can impact performance metrics. Additionally, the use of high-quality components such as the IRFP264N transistors ensures that the testbed can handle significant power levels while maintaining safety and reliability. Overall, the detailed methodology and design considerations outlined in this article provide a robust framework for testing power supplies, contributing to the development of high-performance electronic devices.This article provides a detailed description of our methodology for testing power supplies in three major parts. The first one lists PSU parameters we check out and specifies the test conditions. In the second section you`ll find terms often voiced by PSU manufacturers for marketing purposes and their definitions.

The third part will be most inter esting for people who`d like to know how our PSU testbed is designed and operates. In our PSU tests our main task is to check it out at different loads, up to the maximum one. Many reviewers used to employ an ordinary PC for that purpose, installing the tested PSU into it. This method had two drawbacks: you had no control over the amount of power consumed by the PC, and it was hard to load a really high-wattage PSU. The second problem is especially crucial today when the PSU manufacturers have started a race for reaching as high a wattage rating as possible, and the capabilities of their products have by far exceeded the demands of a typical PC.

Of course, one may argue that there`s no point in testing PSUs at higher loads if no real PC needs more than 500W, but it would be odd not to check out a high-wattage PSU through its entire load range if we begin to test it at all. We use an adjustable load with programmable control to test PSUs in our labs. The testbed is based on the well-known feature of metal-oxide-semiconductor field-effect transistors (MOSFETs): a MOSFET limits the current flowing in the drain-source circuit depending on the voltage in the gate.

Above you can see a simple schematic of a MOSFET-based current regulator: connecting the circuit to a PSU with an output voltage of +V and turning the lever of the variable resistor R1 we are changing the voltage on the gate of the transistor VT1 thus changing the current I that flows through it from zero to maximum (determined by the characteristics of the transistor and/or tested PSU). This circuit is not perfect, though. When the transistor heats up, its characteristics change somewhat and the current I changes, too, although the control voltage on the gate remains the same.

To solve the problem, we need to add a second resistor R2 and an operation amplifier DA1 into the circuit: When the transistor is open, the current I flows through its drain-source circuit and through the resistor R2. The voltage on the latter equals U = R2*I, according to Ohm`s law. This voltage goes to the inverting input of the operation amplifier DA1. The non-inverting input of the same opamp receives the control voltage U1 from the variable resistor R1.

The opamp has such properties that it tries to maintain the same voltage on both its inputs by changing its output voltage, which in our circuit goes to the MOSFET`s gate and regulates the current flowing through it. Suppose the resistance R2 equals 1 Ohm, and we`ve set a voltage of 1V on the resistor R1. Then the opamp will change its output voltage in such a way that the voltage drop on the R2 is 1V, too.

The current I now equals 1V / 1Ohm = 1A. If we set a voltage of 2V on the R1, the opamp will react by setting the current I at 2A, etc. If the current I and, accordingly, the voltage on the resistor R2 changes due to the heating-up of the transistor, the opamp will immediately adjust its output voltage to bring them back. Thus, we have a perfectly controllable load that allows to smoothly change the current from zero to maximum with a turn of a lever.

It maintains the value you set automatically for as long as you wish. It is also compact, being much easier to handle than a clumsy set of low-resistance resistors connected in groups to the tested PSU. The maximum amount of power dissipated on the transistor is determined by its thermal resistance, the maximum allowable die temperature, and the temperature of the heatsink it is installed on.

Our testbed employs International Rectifier IRFP264N transistors (a 168KB. PDF file ) with an allo 🔗 External reference