S1D15G10 Nokia LCD

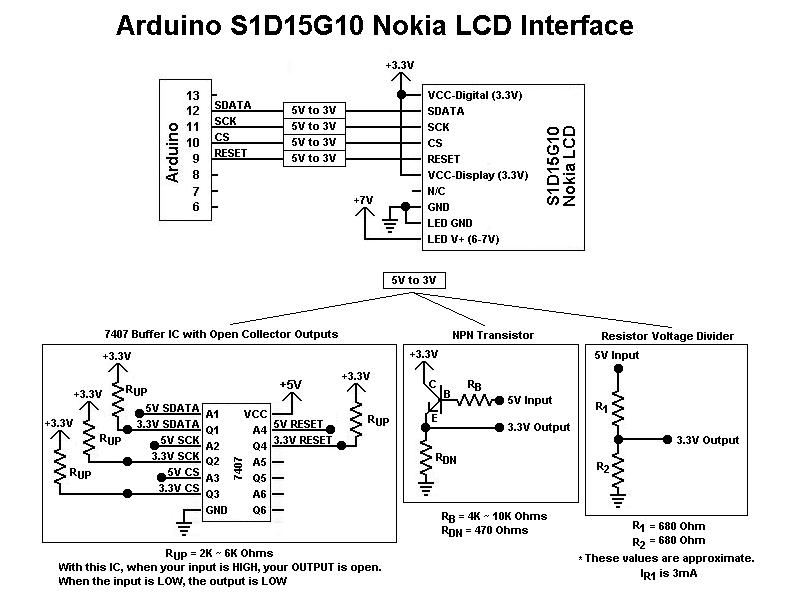

This is the first color graphic LCD display encountered. Initial assumptions were made regarding the connections, specifically that the Chip Select (CS) and RESET pins could be tied high for simplicity, based on previous experience with TTL logic. However, this approach does not yield reliable operation; these pins must be connected to the microcontroller. Proper toggling of these signals is essential for normal functionality. After setting up the connections, there was a desire for an indication that the LCD was functioning correctly. It became evident that without consulting the datasheet, utilizing the LCD would be challenging. Random data could be sent to the display indefinitely without any confirmation of operation. The datasheet includes application notes and a detailed configuration guide, which are vital for successful implementation. Typically, after adjusting the contrast and writing data to the display's RAM, some activity should be observed. Otherwise, powering the LCD and backlight (which is necessary) may result in a blue screen or sporadic lines due to noise. This project has faced significant challenges, likely improved with newer display models. In addition to using an external voltage booster for the backlight, employing an insulated foil ground plane between the display and the breakout board could have been beneficial. This could be achieved by adhering aluminum foil with scotch tape to one side, connecting the foil to ground. The provided code snippet demonstrates a function for drawing a text line on the LCD, utilizing various color parameters and pixel manipulation.

The operation of the color graphic LCD display relies on precise control of its interface signals and proper initialization as outlined in the datasheet. The Chip Select (CS) and RESET lines should be connected to the appropriate GPIO pins of a microcontroller, enabling the microcontroller to manage the display's state effectively. The configuration process typically involves setting up the display's contrast and initializing its RAM with specific data patterns to confirm that the display is operational.

The function `draw_text_line` is designed to render a line of text on the LCD. It takes parameters for foreground color (fcolor), background color (bcolor), and the coordinates (x, y) for positioning the text. The function first sets a bounding box for the text line using `lcd_set_box`, which defines the area of the display that will be affected. The command `sendCMD(RAMWR)` is issued to indicate that data will be written to the display's RAM.

A loop iterates over the bits of the character to determine how to render each pixel based on its value. The switch-case structure evaluates each bit of the character and sends the corresponding color data to the display. The use of bitwise operations allows for efficient manipulation of color values, ensuring that the correct colors are sent to the display based on the specified foreground and background colors.

To mitigate noise issues, which have been problematic in this project, implementing a ground plane using aluminum foil can help stabilize the signal integrity. The foil should be insulated and connected to the ground to reduce electromagnetic interference, which can affect the performance and reliability of the display. This additional measure, along with proper power supply considerations, can lead to improved operation of the LCD display in various applications.This is the first color, graphic LCD display I worked with. I made some assumptions when I first began working with it. From previously working with TTL logic in college, I assumed CS and RESET could just be tied high for simplicity. It wont work if you do that. They must be wired to the micro-controller to get reliable operation from the LCD. Tog gling them is necessary for normal operation. After wiring everything up, I desperately wanted some sign of life from the LCD, to know if it was wired correctly. Figuring out how to use the LCD without reading the datasheet is impossible. You could send random data to the display for a thousand years and never see any indication that it`s working.

Towards the end of the data sheet are application notes and a nice walk through for configuring the display. Usually, after setting the contrast for it, and writing some data to the display`s ram, you`ll see it do something.

Otherwise, simply powering the LCD and back-light (necessary) will give you a blue screen, and maybe just some sporadic lines from noise. Speaking of noise, this project has had the worst problems of any I`ve ever done. It`s probably been resolved by now with newer displays. Aside from using an external voltage booster for the backlight, an insulated foil ground plane could`ve been sandwiched between the display and breakout board.

Scotch tape on one side of aluminum foil, the side against the board, and connect the foil to ground. void NokiaLCD::draw_text_line(word fcolor, word bcolor, byte x, byte y, char c) { lcd_set_box(x, y, x, y+7); sendCMD(RAMWR); char i; for(i=0;i<4;i+) { switch( (0x03<<(i*2) & c) >> (i*2) ){ case 0x00: sendData(bcolor >> 4) & 0xFF); sendData(bcolor & 0xF) << 4) | (bcolor >> 8) & 0xF); sendData(bcolor & 0xFF); break; case 0x01: sendData(fcolor >> 4) & 0xFF); sendData(fcolor & 0xF) << 4) | (bcolor >> 8) & 0xF); sendData(bcolor & 0xFF); break; case 0x02: sendData(bcolor >> 4) & 0xFF); sendData(bcolor & 0xF) << 4) | (fcolor >> 8) & 0xF); sendData(fcolor & 0xFF); break; case 0x03: sendData(fcolor >> 4) & 0xFF); sendData(fcolor & 0xF) << 4) | (fcolor >> 8) & 0xF); sendData(fcolor & 0xFF); break; } } }

🔗 External reference

The operation of the color graphic LCD display relies on precise control of its interface signals and proper initialization as outlined in the datasheet. The Chip Select (CS) and RESET lines should be connected to the appropriate GPIO pins of a microcontroller, enabling the microcontroller to manage the display's state effectively. The configuration process typically involves setting up the display's contrast and initializing its RAM with specific data patterns to confirm that the display is operational.

The function `draw_text_line` is designed to render a line of text on the LCD. It takes parameters for foreground color (fcolor), background color (bcolor), and the coordinates (x, y) for positioning the text. The function first sets a bounding box for the text line using `lcd_set_box`, which defines the area of the display that will be affected. The command `sendCMD(RAMWR)` is issued to indicate that data will be written to the display's RAM.

A loop iterates over the bits of the character to determine how to render each pixel based on its value. The switch-case structure evaluates each bit of the character and sends the corresponding color data to the display. The use of bitwise operations allows for efficient manipulation of color values, ensuring that the correct colors are sent to the display based on the specified foreground and background colors.

To mitigate noise issues, which have been problematic in this project, implementing a ground plane using aluminum foil can help stabilize the signal integrity. The foil should be insulated and connected to the ground to reduce electromagnetic interference, which can affect the performance and reliability of the display. This additional measure, along with proper power supply considerations, can lead to improved operation of the LCD display in various applications.This is the first color, graphic LCD display I worked with. I made some assumptions when I first began working with it. From previously working with TTL logic in college, I assumed CS and RESET could just be tied high for simplicity. It wont work if you do that. They must be wired to the micro-controller to get reliable operation from the LCD. Tog gling them is necessary for normal operation. After wiring everything up, I desperately wanted some sign of life from the LCD, to know if it was wired correctly. Figuring out how to use the LCD without reading the datasheet is impossible. You could send random data to the display for a thousand years and never see any indication that it`s working.

Towards the end of the data sheet are application notes and a nice walk through for configuring the display. Usually, after setting the contrast for it, and writing some data to the display`s ram, you`ll see it do something.

Otherwise, simply powering the LCD and back-light (necessary) will give you a blue screen, and maybe just some sporadic lines from noise. Speaking of noise, this project has had the worst problems of any I`ve ever done. It`s probably been resolved by now with newer displays. Aside from using an external voltage booster for the backlight, an insulated foil ground plane could`ve been sandwiched between the display and breakout board.

Scotch tape on one side of aluminum foil, the side against the board, and connect the foil to ground. void NokiaLCD::draw_text_line(word fcolor, word bcolor, byte x, byte y, char c) { lcd_set_box(x, y, x, y+7); sendCMD(RAMWR); char i; for(i=0;i<4;i+) { switch( (0x03<<(i*2) & c) >> (i*2) ){ case 0x00: sendData(bcolor >> 4) & 0xFF); sendData(bcolor & 0xF) << 4) | (bcolor >> 8) & 0xF); sendData(bcolor & 0xFF); break; case 0x01: sendData(fcolor >> 4) & 0xFF); sendData(fcolor & 0xF) << 4) | (bcolor >> 8) & 0xF); sendData(bcolor & 0xFF); break; case 0x02: sendData(bcolor >> 4) & 0xFF); sendData(bcolor & 0xF) << 4) | (fcolor >> 8) & 0xF); sendData(fcolor & 0xFF); break; case 0x03: sendData(fcolor >> 4) & 0xFF); sendData(fcolor & 0xF) << 4) | (fcolor >> 8) & 0xF); sendData(fcolor & 0xFF); break; } } }

🔗 External reference