Servo motor control

A servo motor is a specialized geared DC motor that includes an electronic circuit for controlling the direction and position of the motor shaft. Due to its capability for precise angular positioning, servo motors are widely utilized in robotics, as well as in radio-controlled cars, airplanes, and boats to manage the movement of various components. This lab session will first investigate the components and operation of a servo motor and then demonstrate how to interface it with a PIC microcontroller. A servo motor, often referred to as a servo, consists of a DC motor, an output shaft (servo arm) connected to the motor via a series of gears, and an electronic circuit for position control. The primary goal of a servo is to achieve accurate angular positioning of an object. To facilitate this function, instantaneous position feedback of the output shaft is relayed to the control circuit using a transducer. A common method for achieving this is by attaching a potentiometer to the output shaft or within the gear train. The control electronics compare the feedback signal, which indicates the current shaft position, with the control input signal, which specifies the desired position. Any discrepancy between the actual and desired values, known as the error signal, is amplified and used to drive the DC motor in the direction required to minimize the error. The error becomes zero when the output shaft reaches the desired position. A typical servo motor operates using a pulse width modulated (PWM) control input signal at a frequency of 50 Hz, meaning the pulse repeats every 20 ms. The pulse width determines the angular position of the output shaft. An internal electronic circuit within the servo converts the PWM signal to a proportional output voltage, which is then compared with the feedback voltage from the potentiometer. If a difference exists, the control circuit drives the motor in the appropriate direction until the difference is eliminated. Typical pulse width values range from 1.0 to 2.0 milliseconds (ms). For standard servos, a pulse width between 1.0 ms and 1.5 ms causes the servo to turn clockwise (CW), while a pulse width between 1.5 ms and 2.0 ms results in a counterclockwise (CCW) rotation. A pulse width of 1.5 ms positions the servo motor at its center. However, these values may vary depending on the specific brand and model, so it is advisable to consult the servo's datasheet for accurate pulse width specifications for different angles. Most servos are capable of rotating through 180°, although some can rotate a full 360° or more. Servos are commonly employed as moving joints in robotic arms due to their precise angular positioning capabilities and are also used in radio-controlled (RC) toys. For instance, in RC cars, servos are used in steering mechanisms, while in RC boats, they control the rudder. A servo motor typically has three wires: two for power supply (Vcc and Ground) and one for the control signal. The Vcc wire is generally red, the ground wire is black or brown, and the control signal wire is white, yellow, or orange. In this experiment, the servo motor from iCircuit Technologies has red, brown, and yellow wires for Vcc, Ground, and control signal, respectively. It operates at a power supply of 5.0 V and provides angular rotation through 180°. The pulse width values for various angular positions of this servo are specified in a table. It is essential to maintain a pulse repetition rate of 50 Hz (20 ms period). The circuit diagram for this experiment illustrates the control input for the servo, which is derived from the RB1 pin of the PIC16F microcontroller.

The servo motor's operation relies on feedback control to ensure accurate positioning. The internal components include the DC motor, gears, a potentiometer for feedback, and a control circuit that processes the PWM signal. The potentiometer provides continuous feedback on the shaft's position, enabling the control circuit to make real-time adjustments to the motor's operation. The PWM signal, which varies in width, effectively communicates the desired angle to the servo. As the PWM signal changes, the control circuit interprets these changes and drives the motor accordingly to achieve the specified position.

In practical applications, the interfacing of a servo motor with a PIC microcontroller is accomplished through a simple circuit. The control pin of the servo is connected to a designated output pin on the PIC microcontroller, which generates the PWM signal. The microcontroller can be programmed to produce varying pulse widths based on user input or sensor data, allowing for dynamic control of the servo's position. The power supply connections are made to ensure the servo receives the appropriate voltage for operation, while the ground connection provides a common reference point for the circuit.

In summary, the servo motor is a versatile component widely used in various applications requiring precise motion control. Its integration with microcontrollers allows for sophisticated control mechanisms in robotics and remote-controlled devices, making it an essential element in modern electronic design.A servo motor is a special geared DC motor equipped with an electronic circuit for controlling the direction of rotation, as well as the position, of the motor shaft. Because servo motors allows precise angular positioning of their output shaft, they are used extensively in robotics and radio-controlled cars, airplanes, and boats to control the mo

tion of their various parts. In this lab session, we will first explore what a servo motor consists of and how it works and then illustrate how to interface it with a PIC microcontroller. A servo motor (or servo) is a little box that contains a DC motor, an output shaft (servo arm) which is connected to the motor through a series of gears, and an electronic circuit to control the position of the shaft.

The objective of using a servo is to achieve precise angular positioning of an object. In order to accomplish a servo function, an instantaneous positioning information of the output shaft is fed back to the control circuit using a transducer. A simplest way of doing this is by attaching a potentiometer to the output shaft or somewhere in the gear train.

The control electronics compares the feedback signal (which contains the current position of the shaft) from the potentiometer to the control input signal (which contains information of the desired position of the shaft), and any difference between the actual and desired values (known as an error signal) is amplified and used to drive the DC motor in a direction necessary to reduce or eliminate the error. The error is zero when the output shaft gets to the desired position. The functioning block diagram of a typical servomotor is shown below. The control input to a servo is a pulse width modulated (PWM) signal, generally of frequency 50 Hz. This means the pulse should repeat every 20ms. The width of the pulse determines the angular position of the output shaft. An electronic circuit inside the servo converts the PWM signal to a proportional output voltage which is compared with the feedback voltage from the potentiometer.

If a difference exists between the two, the control circuit drives the motor in an appropriate direction until the difference becomes zero. A typical value of the pulse width is somewhere in the range of 1. 0 to 2. 0 milliseconds (ms). For a standard servo, a pulse width between 1. 0 ms to 1. 5 ms makes the servo to turn clockwise (CW), between 1. 5 ms to 2. 0 ms makes it to turn counterclockwise (CCW), and a 1. 5 ms pulse width turns the servo motor to its center. However, these values could vary depending on the brand and make of the motor. It is advised to read the datasheet of the servo to find the true values of the pulse widths required for positioning the servo at different angles.

Most servos rotate through 180 °. However. there are some that could rotate through a full 360 ° or more. Servos are widely used as the moving joints in robotic arms for their precise angular positioning. They also finds applications in radio controlled (RC) toys. For example, in RC cars they are used in the steering mechanisms, and in RC boats to control the rudder. A servomotor has three wires: two are designated for power supply (Vcc and Ground) and the third wire is for the control signal.

The Vcc wire is usually red and the ground one is either black or brown. Thecontrol signal wire comes in white, yellow, or orange color. The servomotor used in this experiment is from iCircuit technologies and has red, brown, and yellow color wires for Vcc, Gnd, and control signal, respectively. It operates at 5. 0 V power supply and provides angular rotation through 180 ° The pulse width values for different angular positions of this servo are provided in the table below.

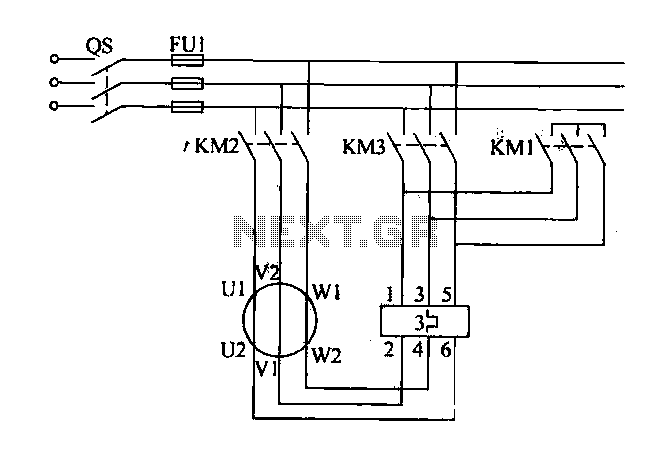

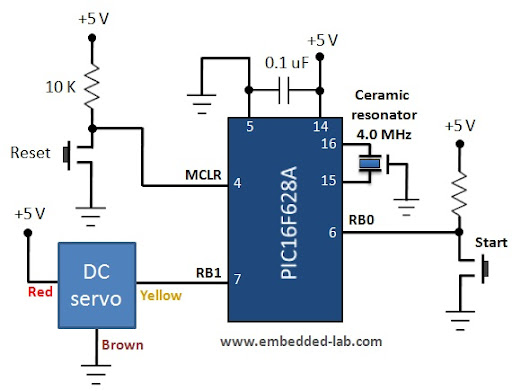

Remember that the repetition rate of the pulse should be 50 Hz (period of 20 ms). The circuit diagram of this experiment is depicted below. The control input for the servo is derived from the RB1 pin of the PIC16F 🔗 External reference

The servo motor's operation relies on feedback control to ensure accurate positioning. The internal components include the DC motor, gears, a potentiometer for feedback, and a control circuit that processes the PWM signal. The potentiometer provides continuous feedback on the shaft's position, enabling the control circuit to make real-time adjustments to the motor's operation. The PWM signal, which varies in width, effectively communicates the desired angle to the servo. As the PWM signal changes, the control circuit interprets these changes and drives the motor accordingly to achieve the specified position.

In practical applications, the interfacing of a servo motor with a PIC microcontroller is accomplished through a simple circuit. The control pin of the servo is connected to a designated output pin on the PIC microcontroller, which generates the PWM signal. The microcontroller can be programmed to produce varying pulse widths based on user input or sensor data, allowing for dynamic control of the servo's position. The power supply connections are made to ensure the servo receives the appropriate voltage for operation, while the ground connection provides a common reference point for the circuit.

In summary, the servo motor is a versatile component widely used in various applications requiring precise motion control. Its integration with microcontrollers allows for sophisticated control mechanisms in robotics and remote-controlled devices, making it an essential element in modern electronic design.A servo motor is a special geared DC motor equipped with an electronic circuit for controlling the direction of rotation, as well as the position, of the motor shaft. Because servo motors allows precise angular positioning of their output shaft, they are used extensively in robotics and radio-controlled cars, airplanes, and boats to control the mo

tion of their various parts. In this lab session, we will first explore what a servo motor consists of and how it works and then illustrate how to interface it with a PIC microcontroller. A servo motor (or servo) is a little box that contains a DC motor, an output shaft (servo arm) which is connected to the motor through a series of gears, and an electronic circuit to control the position of the shaft.

The objective of using a servo is to achieve precise angular positioning of an object. In order to accomplish a servo function, an instantaneous positioning information of the output shaft is fed back to the control circuit using a transducer. A simplest way of doing this is by attaching a potentiometer to the output shaft or somewhere in the gear train.

The control electronics compares the feedback signal (which contains the current position of the shaft) from the potentiometer to the control input signal (which contains information of the desired position of the shaft), and any difference between the actual and desired values (known as an error signal) is amplified and used to drive the DC motor in a direction necessary to reduce or eliminate the error. The error is zero when the output shaft gets to the desired position. The functioning block diagram of a typical servomotor is shown below. The control input to a servo is a pulse width modulated (PWM) signal, generally of frequency 50 Hz. This means the pulse should repeat every 20ms. The width of the pulse determines the angular position of the output shaft. An electronic circuit inside the servo converts the PWM signal to a proportional output voltage which is compared with the feedback voltage from the potentiometer.

If a difference exists between the two, the control circuit drives the motor in an appropriate direction until the difference becomes zero. A typical value of the pulse width is somewhere in the range of 1. 0 to 2. 0 milliseconds (ms). For a standard servo, a pulse width between 1. 0 ms to 1. 5 ms makes the servo to turn clockwise (CW), between 1. 5 ms to 2. 0 ms makes it to turn counterclockwise (CCW), and a 1. 5 ms pulse width turns the servo motor to its center. However, these values could vary depending on the brand and make of the motor. It is advised to read the datasheet of the servo to find the true values of the pulse widths required for positioning the servo at different angles.

Most servos rotate through 180 °. However. there are some that could rotate through a full 360 ° or more. Servos are widely used as the moving joints in robotic arms for their precise angular positioning. They also finds applications in radio controlled (RC) toys. For example, in RC cars they are used in the steering mechanisms, and in RC boats to control the rudder. A servomotor has three wires: two are designated for power supply (Vcc and Ground) and the third wire is for the control signal.

The Vcc wire is usually red and the ground one is either black or brown. Thecontrol signal wire comes in white, yellow, or orange color. The servomotor used in this experiment is from iCircuit technologies and has red, brown, and yellow color wires for Vcc, Gnd, and control signal, respectively. It operates at 5. 0 V power supply and provides angular rotation through 180 ° The pulse width values for different angular positions of this servo are provided in the table below.

Remember that the repetition rate of the pulse should be 50 Hz (period of 20 ms). The circuit diagram of this experiment is depicted below. The control input for the servo is derived from the RB1 pin of the PIC16F 🔗 External reference