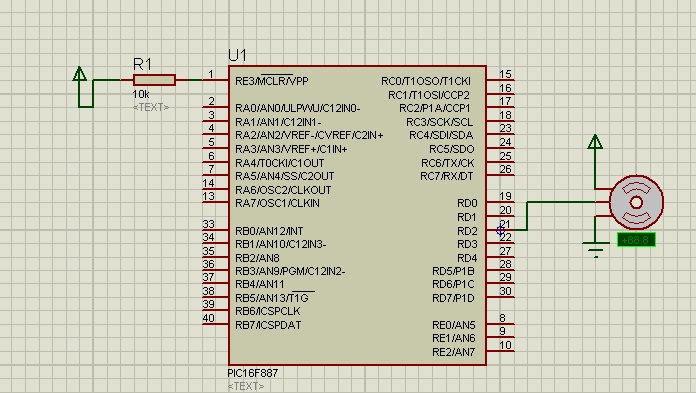

servo motor control with microcontroller

The shaft can be positioned at specific angular positions by sending a coded signal to the servo. As long as the coded signal is present on the input line, the servo will maintain the angular position of the shaft. Changes in the coded signal result in changes to the angular position of the shaft. In practical applications, servos are utilized in radio-controlled airplanes to position control surfaces such as elevators and rudders. They are also employed in radio-controlled cars, puppets, and robots. The internal components of a servo motor include control circuitry, a motor, a set of gears, and a casing. Three wires connect the servo to external sources: one for power (+5 volts), one for ground, and a control wire. The servo motor incorporates control circuits and a potentiometer (variable resistor) linked to the output shaft, which allows the control circuitry to monitor the current angle of the servo motor. If the shaft is positioned correctly, the motor turns off; if not, the circuit directs the motor to turn in the appropriate direction until the desired angle is achieved. The output shaft of the servo typically has a travel range of approximately 180 degrees, although it can extend to around 210 degrees depending on the manufacturer. A standard servo is designed to control angular motion between 0 and 180 degrees, with mechanical stops preventing further rotation. The power applied to the motor is proportional to the distance it needs to travel; thus, a larger distance results in higher motor speed, while a smaller distance results in slower motor speed. This mechanism is known as proportional control. The control wire communicates the desired angle, which is determined by the duration of a pulse applied to the control wire, a method referred to as Pulse Coded Modulation. The servo expects a pulse every 20 milliseconds (0.02 seconds), and the pulse length dictates the motor's rotation. For instance, a 1.5-millisecond pulse positions the motor at the 90-degree (neutral) position. Pulses shorter than 1.5 milliseconds cause the motor to turn towards 0 degrees, while longer pulses move it closer to 180 degrees.

The servo motor operates based on a feedback control system that ensures accurate positioning of the output shaft. The core components of a servo include the DC motor, control circuitry, a potentiometer, and a gear train. The control circuitry interprets the signal received through the control wire and adjusts the motor's operation accordingly. The potentiometer, connected to the output shaft, serves as a feedback mechanism by providing real-time information about the current angle of the shaft to the control circuitry.

The gear train amplifies the torque produced by the motor, allowing the servo to exert sufficient force to move the connected load. The design of the gear train can influence the speed and torque characteristics of the servo. For instance, a higher gear ratio results in increased torque but reduced speed, while a lower gear ratio produces higher speeds at the expense of torque.

Pulse Coded Modulation (PCM) is a key aspect of servo control. The servo interprets the duration of the pulse width to determine the target angle. The standard pulse width for neutral position is 1.5 milliseconds, with variations for other angles. For example, a pulse width of 1 millisecond typically corresponds to the minimum angle (0 degrees), while a pulse width of 2 milliseconds corresponds to the maximum angle (180 degrees). The servo's ability to maintain its position while receiving a continuous signal ensures precise control in applications such as robotics and aeronautics.

In summary, the servo motor's design and operation allow for precise control of angular motion through a combination of electronic signals, mechanical components, and feedback systems. The integration of these elements enables a wide range of applications, making servos essential in various fields, including robotics, automation, and remote-controlled devices.This shaft can be positioned to specific angular positions by sending the servo a coded signal. As long as the coded signal exists on the input line, the servo will maintain the angular position of the shaft. As the coded signal changes, the angular position of the shaft changes. In practice, servos are used in radio controlled airplanes to position control surfaces like the elevators and rudders. They are also used in radio controlled cars, puppets, and of course, robots. The guts of a servo motor are shown in the picture below. You can see the control circuitry, the motor, a set of gears, and the case. You can also see the 3 wires that connect to the outside world. One is for power (+5volts), ground, and the white wire is the control wire. So, how does a servo work The servo motor has some control circuits and a potentiometer (a variable resistor, aka pot) that is connected to the output shaft. In the picture above, the pot can be seen on the right side of the circuit board. This pot allows the control circuitry to monitor the current angle of the servo motor. If the shaft is at the correct angle, then the motor shuts off. If the circuit finds that the angle is not correct, it will turn the motor the correct direction until the angle is correct.

The output shaft of the servo is capable of travelling somewhere around 180 degrees. Usually, its somewhere in the 210 degree range, but it varies by manufacturer. A normal servo is used to control an angular motion of between 0 and 180 degrees. A normal servo is mechanically not capable of turning any farther due to a mechanical stop built on to the main output gear. The amount of power applied to the motor is proportional to the distance it needs to travel. So, if the shaft needs to turn a large distance, the motor will run at full speed. If it needs to turn only a small amount, the motor will run at a slower speed. This is called proportional control. How do you communicate the angle at which the servo should turn The control wire is used to communicate the angle.

The angle is determined by the duration of a pulse that is applied to the control wire. This is called Pulse Coded Modulation. The servo expects to see a pulse every 20 milliseconds (. 02 seconds). The length of the pulse will determine how far the motor turns. A 1. 5 millisecond pulse, for example, will make the motor turn to the 90 degree position (often called the neutral position). If the pulse is shorter than 1. 5 ms, then the motor will turn the shaft to closer to 0 degress. If the pulse is longer than 1. 5ms, the shaft turns closer to 180 degress. 🔗 External reference

The servo motor operates based on a feedback control system that ensures accurate positioning of the output shaft. The core components of a servo include the DC motor, control circuitry, a potentiometer, and a gear train. The control circuitry interprets the signal received through the control wire and adjusts the motor's operation accordingly. The potentiometer, connected to the output shaft, serves as a feedback mechanism by providing real-time information about the current angle of the shaft to the control circuitry.

The gear train amplifies the torque produced by the motor, allowing the servo to exert sufficient force to move the connected load. The design of the gear train can influence the speed and torque characteristics of the servo. For instance, a higher gear ratio results in increased torque but reduced speed, while a lower gear ratio produces higher speeds at the expense of torque.

Pulse Coded Modulation (PCM) is a key aspect of servo control. The servo interprets the duration of the pulse width to determine the target angle. The standard pulse width for neutral position is 1.5 milliseconds, with variations for other angles. For example, a pulse width of 1 millisecond typically corresponds to the minimum angle (0 degrees), while a pulse width of 2 milliseconds corresponds to the maximum angle (180 degrees). The servo's ability to maintain its position while receiving a continuous signal ensures precise control in applications such as robotics and aeronautics.

In summary, the servo motor's design and operation allow for precise control of angular motion through a combination of electronic signals, mechanical components, and feedback systems. The integration of these elements enables a wide range of applications, making servos essential in various fields, including robotics, automation, and remote-controlled devices.This shaft can be positioned to specific angular positions by sending the servo a coded signal. As long as the coded signal exists on the input line, the servo will maintain the angular position of the shaft. As the coded signal changes, the angular position of the shaft changes. In practice, servos are used in radio controlled airplanes to position control surfaces like the elevators and rudders. They are also used in radio controlled cars, puppets, and of course, robots. The guts of a servo motor are shown in the picture below. You can see the control circuitry, the motor, a set of gears, and the case. You can also see the 3 wires that connect to the outside world. One is for power (+5volts), ground, and the white wire is the control wire. So, how does a servo work The servo motor has some control circuits and a potentiometer (a variable resistor, aka pot) that is connected to the output shaft. In the picture above, the pot can be seen on the right side of the circuit board. This pot allows the control circuitry to monitor the current angle of the servo motor. If the shaft is at the correct angle, then the motor shuts off. If the circuit finds that the angle is not correct, it will turn the motor the correct direction until the angle is correct.

The output shaft of the servo is capable of travelling somewhere around 180 degrees. Usually, its somewhere in the 210 degree range, but it varies by manufacturer. A normal servo is used to control an angular motion of between 0 and 180 degrees. A normal servo is mechanically not capable of turning any farther due to a mechanical stop built on to the main output gear. The amount of power applied to the motor is proportional to the distance it needs to travel. So, if the shaft needs to turn a large distance, the motor will run at full speed. If it needs to turn only a small amount, the motor will run at a slower speed. This is called proportional control. How do you communicate the angle at which the servo should turn The control wire is used to communicate the angle.

The angle is determined by the duration of a pulse that is applied to the control wire. This is called Pulse Coded Modulation. The servo expects to see a pulse every 20 milliseconds (. 02 seconds). The length of the pulse will determine how far the motor turns. A 1. 5 millisecond pulse, for example, will make the motor turn to the 90 degree position (often called the neutral position). If the pulse is shorter than 1. 5 ms, then the motor will turn the shaft to closer to 0 degress. If the pulse is longer than 1. 5ms, the shaft turns closer to 180 degress. 🔗 External reference