Simple Characterization Circuit for Rechargeable AA Cells

This characterization circuit, along with a PC and specific software, accurately measures the complete discharge cycle of a rechargeable AA cell. The capacity and output resistance of the cell can be easily determined from the resulting curve of these measurements. Rechargeable AA cells are widely used in various portable applications, and there is a significant variety of brands, resulting in considerable differences in cell quality. The actual capacity of these cells can often differ from the specifications, and their capacity tends to deteriorate significantly after a limited number of discharge cycles. The proposed characterization circuit, in conjunction with a PC and AA-Cell Characterizer software, can accurately measure a full discharge cycle. The circuit is centered around an integrated circuit (IC) designed for fuel-gauging applications in battery packs (DS2756). The DS2756 includes essential components for accurately estimating the remaining capacity of a battery pack by integrating low-power precision measurements of temperature, voltage, current, and current accumulation (integral of current). This hardware can also accurately record the discharge cycle of a single AA cell (either NiCd or NiMH). The simple circuit connects to the USB port of a PC, eliminating the need for an external power source as it draws power from the USB bus voltage. U1 (DS9490R) is a USB dongle that converts the USB protocol to the 1-Wire® protocol, facilitating communication between the PC and the key circuit component (U2). U2 measures the cell voltage at pin 1 (VIN) through R1 and the cell current through R4, which is a 25mΩ sense resistor connected to pins 7 (SNS) and 2 (VSS). The programmable I/O at pin 3 (PIO) allows the PC software to control the gate of Q1. When PIO is high, Q1 turns on, applying a load to the cell via R2, resulting in a discharge current of approximately 1A. Conversely, when PIO is low, Q1 turns off, removing the load from the cell. Diode D1 is included to reduce the 5V USB voltage, ensuring that VDD remains below the maximum allowable voltage of 4.5V. The AA-Cell Characterizer software, developed in Visual Basic, conducts the cell discharge cycle. Upon installation, the software initializes U2 and switches off Q1. When a fully charged cell is inserted, the software displays the measured cell voltage. After initiating the measurement, the software activates Q1 and logs the cell voltage and current every second. Following each logged point, Q1 briefly switches off to measure the unloaded cell voltage, which is also recorded. To prevent damage to the cell, the measurement process automatically halts when the cell voltage falls below a predetermined limit, which can be adjusted and is stored in the EEPROM memory of the DS2756, with a default value of 800mV. Measurements can also be stopped manually, and the logged data can be saved for further analysis. Given the small size of the sense resistor, variations may occur due to soldering connections, and the resistor value used by the software can be calibrated. Calibration involves starting the software, bypassing Q1 with an ammeter, and adjusting the resistor value until the readings match. The new value is stored in EEPROM for future use, with a default value of 25.00mΩ. The logged data can be analyzed using Microsoft® Excel® by importing the log file.

The characterization circuit is designed to provide a comprehensive analysis of rechargeable AA cells, ensuring accurate measurements of both capacity and output resistance. The integration of the DS2756 IC allows for precise monitoring of the cell's voltage and current throughout the discharge cycle. The use of a USB interface simplifies the connection to a PC, facilitating easy data logging and analysis without the need for an external power supply. The software interface enhances user interaction, allowing for straightforward initiation of measurements and easy access to logged data. The calibration process ensures that the system maintains accuracy over time, accommodating variations in the sense resistor and ensuring reliable readings. This system is particularly valuable for applications where battery performance is critical, enabling users to assess the health and capacity of rechargeable AA cells effectively.This characterization circuit, plus a PC and some software, accurately measures the full discharge cycle for a rechargeable AA cell. Cell capacity and output resistance can easily be determined from the curve resulting from these measurements.

Rechargeable AA cells are very popular for a large variety of portable applications. The number of brands is also high and the cell quality can differ considerably. Cell capacity is sometimes different from that specified, and the capacity often deteriorates dramatically after a limited number of discharge cycles. The proposed characterization circuit, in combination with a PC and AA-Cell Characterizer software, can accurately measure a full discharge cycle.

From the resulting curve you can easily determine the cell capacity and output resistance. The circuit is built around an IC intended for fuel-gauging applications in battery packs ( DS2756 ). The DS2756 provides the key components necessary to accurately estimate remaining battery-pack capacity by integrating low-power precision measurements of temperature, voltage, current, and current accumulation (integral of current).

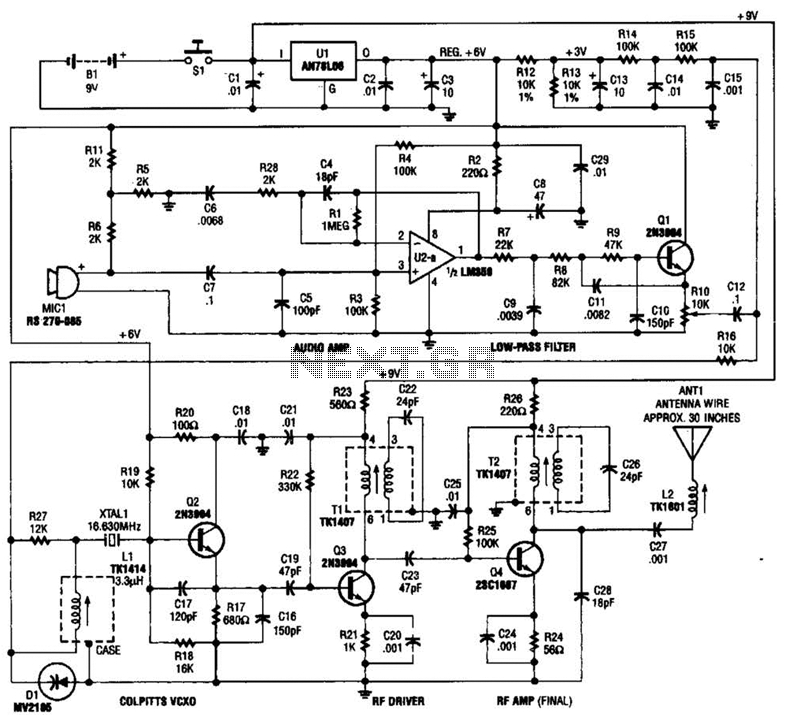

This hardware can also record the discharge cycle of a single AA cell (either NiCd or NiMH ) with accuracy. In Figure 1, the simple circuit is connected to the USB port of a PC. No external power source is required because power is extracted from the USB bus voltage. U1 ( DS9490R ) is a USB dongle that converts the USB protocol to the 1-Wire ® protocol, thereby allowing the PC to communicate with the key circuit component (U2).

U2 measures the cell voltage on pin 1 (VIN) through R1, the cell current through R4, a 25m © sense resistor connected to pins 7 (SNS) and 2 (VSS). The programmable I/O at pin 3 (PIO) allows PC software to control the gate of Q1. When PIO is high, Q1 switches on and loads the cell with R2. That connection causes a discharge current of approximately 1A. When PIO is low, Q1 switches off and removes the cell load. Diode D1 is required to lower the 5V USB voltage to keep VDD below the maximum allowed voltage of 4. 5V. The AA-Cell Characterizer software, written in Visual Basic, performs the cell discharge cycle. (Note: please see Drivers and Additional Software below before installing this software. ) This software initializes U2 and switches off Q1. When you insert a fully charged cell, the software indicates the measured cell voltage (Figure 2a). After you click "Start Measurement, " the software switches on Q1 and then logs the cell voltage and current every second.

After each logged point, Q1 switches off shortly to allow measurement of the unloaded cell voltage, which is also logged (Figure 2b). To prevent cell damage, the measurement is stopped automatically when the cell voltage drops below a certain limit.

This limit can be modified and is stored in the EEPROM memory of the DS2756. The value defaults to 800mV. After a measurement has been stopped, the "Accumulated Current" field shows how much charge has been drawn from the cell and indicates the actual cell capacity. The measurement can also be stopped manually by clicking the "Stop Measurement" button. Clicking "Save Data" saves the logged data to disk for further analysis. Since the sense resistor is very small, there can be some variation due to soldering connections. The resistor value used by the software can be adjusted for calibration. To calibrate the resistor, first start the software. Next, bypass Q1 with an ampere meter connected between source and drain. Then connect a battery and monitor the current reported by the ampere meter and the software. Adjust the resistor value so that both values match. The new value is stored in the EEPROM memory for future measurements. The default value is 25. 00m ©. The measured data can be analyzed with a Microsoft ® Excel ® spreadsheet. You can import the log file by clicking "File" and "Open, " and then choose "All Fil 🔗 External reference

The characterization circuit is designed to provide a comprehensive analysis of rechargeable AA cells, ensuring accurate measurements of both capacity and output resistance. The integration of the DS2756 IC allows for precise monitoring of the cell's voltage and current throughout the discharge cycle. The use of a USB interface simplifies the connection to a PC, facilitating easy data logging and analysis without the need for an external power supply. The software interface enhances user interaction, allowing for straightforward initiation of measurements and easy access to logged data. The calibration process ensures that the system maintains accuracy over time, accommodating variations in the sense resistor and ensuring reliable readings. This system is particularly valuable for applications where battery performance is critical, enabling users to assess the health and capacity of rechargeable AA cells effectively.This characterization circuit, plus a PC and some software, accurately measures the full discharge cycle for a rechargeable AA cell. Cell capacity and output resistance can easily be determined from the curve resulting from these measurements.

Rechargeable AA cells are very popular for a large variety of portable applications. The number of brands is also high and the cell quality can differ considerably. Cell capacity is sometimes different from that specified, and the capacity often deteriorates dramatically after a limited number of discharge cycles. The proposed characterization circuit, in combination with a PC and AA-Cell Characterizer software, can accurately measure a full discharge cycle.

From the resulting curve you can easily determine the cell capacity and output resistance. The circuit is built around an IC intended for fuel-gauging applications in battery packs ( DS2756 ). The DS2756 provides the key components necessary to accurately estimate remaining battery-pack capacity by integrating low-power precision measurements of temperature, voltage, current, and current accumulation (integral of current).

This hardware can also record the discharge cycle of a single AA cell (either NiCd or NiMH ) with accuracy. In Figure 1, the simple circuit is connected to the USB port of a PC. No external power source is required because power is extracted from the USB bus voltage. U1 ( DS9490R ) is a USB dongle that converts the USB protocol to the 1-Wire ® protocol, thereby allowing the PC to communicate with the key circuit component (U2).

U2 measures the cell voltage on pin 1 (VIN) through R1, the cell current through R4, a 25m © sense resistor connected to pins 7 (SNS) and 2 (VSS). The programmable I/O at pin 3 (PIO) allows PC software to control the gate of Q1. When PIO is high, Q1 switches on and loads the cell with R2. That connection causes a discharge current of approximately 1A. When PIO is low, Q1 switches off and removes the cell load. Diode D1 is required to lower the 5V USB voltage to keep VDD below the maximum allowed voltage of 4. 5V. The AA-Cell Characterizer software, written in Visual Basic, performs the cell discharge cycle. (Note: please see Drivers and Additional Software below before installing this software. ) This software initializes U2 and switches off Q1. When you insert a fully charged cell, the software indicates the measured cell voltage (Figure 2a). After you click "Start Measurement, " the software switches on Q1 and then logs the cell voltage and current every second.

After each logged point, Q1 switches off shortly to allow measurement of the unloaded cell voltage, which is also logged (Figure 2b). To prevent cell damage, the measurement is stopped automatically when the cell voltage drops below a certain limit.

This limit can be modified and is stored in the EEPROM memory of the DS2756. The value defaults to 800mV. After a measurement has been stopped, the "Accumulated Current" field shows how much charge has been drawn from the cell and indicates the actual cell capacity. The measurement can also be stopped manually by clicking the "Stop Measurement" button. Clicking "Save Data" saves the logged data to disk for further analysis. Since the sense resistor is very small, there can be some variation due to soldering connections. The resistor value used by the software can be adjusted for calibration. To calibrate the resistor, first start the software. Next, bypass Q1 with an ampere meter connected between source and drain. Then connect a battery and monitor the current reported by the ampere meter and the software. Adjust the resistor value so that both values match. The new value is stored in the EEPROM memory for future measurements. The default value is 25. 00m ©. The measured data can be analyzed with a Microsoft ® Excel ® spreadsheet. You can import the log file by clicking "File" and "Open, " and then choose "All Fil 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713