simple intercom circuit with

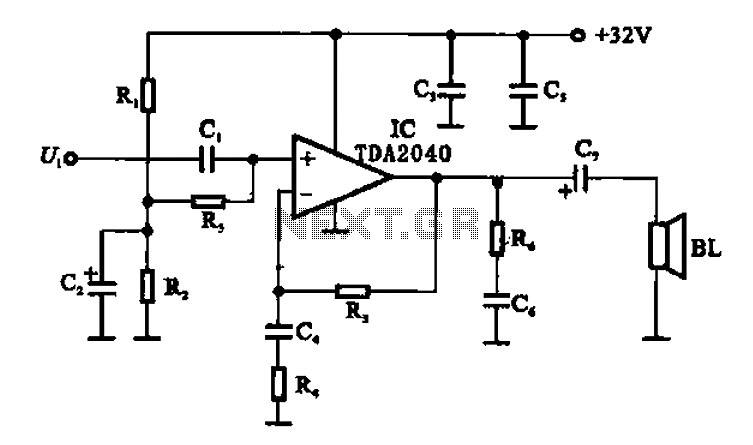

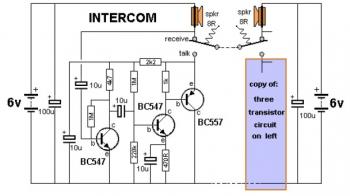

This is a two-station simple intercom circuit built using transistors and common 8-ohm mini speakers. The speaker functions as a microphone and generates sound, eliminating the need for a separate microphone in this intercom setup. The "press-to-talk" switches should have a spring-return mechanism to ensure the intercom cannot be left in the ON position; a push-on switch can be utilized for this purpose. To prevent instability (motor-boating) in a high-gain circuit like this, it is essential to power the speaker from a separate power supply. An additional station (or two extra stations) can be connected to this circuit design. The circuit should be constructed in two separate enclosures for the two stations. Each enclosure should include two ports: one for an external power supply (if not using a battery) and another for connecting to other stations. Holes should be created for the speaker push-on switch. The printed circuit board (PCB) can be designed in a straightforward manner. PCB design software, such as Eagle, can be used to create the layout, which should then be printed on photo paper or glossy paper with a laser printer. The printed design should be adhered to the copper side of the PCB and heated with a hot iron plate to transfer the ink, preparing it for the etching process. If a laser printer is unavailable, the design can be printed on standard paper and copied at a local copy service using glossy paper.

This two-station intercom circuit utilizes a straightforward design that leverages transistors for amplification and mini speakers for both audio output and input. The circuit operates by having each station equipped with a speaker that captures sound when the "press-to-talk" switch is activated, allowing for two-way communication. The use of 8-ohm mini speakers is advantageous due to their compact size and adequate sound quality for intercom applications.

To enhance the reliability of the circuit, the inclusion of a spring-return switch mechanism is critical. This design choice ensures that the intercom remains in a non-active state when the switch is not pressed, thus preventing accidental activation. Furthermore, powering the speakers from a separate power supply mitigates the risk of instability often associated with high-gain circuits, ensuring clear and uninterrupted audio transmission.

The modular approach of constructing each station in separate enclosures facilitates easy installation and maintenance. The inclusion of power supply ports allows for flexibility in the choice of power sources, accommodating both battery and external power options. Additionally, the connection ports enable straightforward linking of multiple intercom stations, allowing for the expansion of the system as needed.

The PCB design process is simplified through the use of dedicated software, which allows for precise layout planning and component placement. The transfer method using a laser printer ensures that the circuit design is accurately replicated onto the PCB, preparing it for the etching process that will create the necessary conductive pathways. This method is efficient and accessible, enabling users to produce a functional intercom circuit with minimal resources. Overall, this intercom design is practical, scalable, and user-friendly, making it suitable for various communication needs.This is a 2-station simple intercom circuit build based on transistors part and using common 8R mini speakers. The speaker works as microphone and generate sound, so there is no need microphone for this intercom.

The "press-to-talk" switches should have a spring-return so the intercom can never be left ON, push on switch can be used for this kind of task. The secret to preventing instability (motor-boating) with a high gain circuit like this is to power the speaker from a separate power supply ! You can connect an extra station (or two extra stations) to this circuit design. Build the circuit into two separated boxes (for 2 stations). On each box should be use 2 ports for external power supply port (if you use external power supply, not battery) and connection port to other stations.

Create some holes for speaker push on switch. Make a PCB in very easy steps. ! Create your PCB design using PCB designer software like Eagle, print out your design on photo paper or glossy paper with laserjet printer. Stick the printed design on the PCB (copper side) and then heat it using hot iron plate. The ink will stick on the PCB and it will be ready for etching process. Note: If you don`t have laserjet printer, then you can print the design on standard paper. Copy the printed design at Copy Service around your location (with glossy paper). 🔗 External reference

This two-station intercom circuit utilizes a straightforward design that leverages transistors for amplification and mini speakers for both audio output and input. The circuit operates by having each station equipped with a speaker that captures sound when the "press-to-talk" switch is activated, allowing for two-way communication. The use of 8-ohm mini speakers is advantageous due to their compact size and adequate sound quality for intercom applications.

To enhance the reliability of the circuit, the inclusion of a spring-return switch mechanism is critical. This design choice ensures that the intercom remains in a non-active state when the switch is not pressed, thus preventing accidental activation. Furthermore, powering the speakers from a separate power supply mitigates the risk of instability often associated with high-gain circuits, ensuring clear and uninterrupted audio transmission.

The modular approach of constructing each station in separate enclosures facilitates easy installation and maintenance. The inclusion of power supply ports allows for flexibility in the choice of power sources, accommodating both battery and external power options. Additionally, the connection ports enable straightforward linking of multiple intercom stations, allowing for the expansion of the system as needed.

The PCB design process is simplified through the use of dedicated software, which allows for precise layout planning and component placement. The transfer method using a laser printer ensures that the circuit design is accurately replicated onto the PCB, preparing it for the etching process that will create the necessary conductive pathways. This method is efficient and accessible, enabling users to produce a functional intercom circuit with minimal resources. Overall, this intercom design is practical, scalable, and user-friendly, making it suitable for various communication needs.This is a 2-station simple intercom circuit build based on transistors part and using common 8R mini speakers. The speaker works as microphone and generate sound, so there is no need microphone for this intercom.

The "press-to-talk" switches should have a spring-return so the intercom can never be left ON, push on switch can be used for this kind of task. The secret to preventing instability (motor-boating) with a high gain circuit like this is to power the speaker from a separate power supply ! You can connect an extra station (or two extra stations) to this circuit design. Build the circuit into two separated boxes (for 2 stations). On each box should be use 2 ports for external power supply port (if you use external power supply, not battery) and connection port to other stations.

Create some holes for speaker push on switch. Make a PCB in very easy steps. ! Create your PCB design using PCB designer software like Eagle, print out your design on photo paper or glossy paper with laserjet printer. Stick the printed design on the PCB (copper side) and then heat it using hot iron plate. The ink will stick on the PCB and it will be ready for etching process. Note: If you don`t have laserjet printer, then you can print the design on standard paper. Copy the printed design at Copy Service around your location (with glossy paper). 🔗 External reference