Solent Radio Control Model Boat Club

A servo controller has evolved from a "servo slower" unit, designed to reduce the slew rate (traverse time) of proportional servos. In model boats, this device is commonly used to control the rotation of a servo-driven gun turret, as direct transmitter stick movement can lead to overly rapid or jerky motions. With a servo controller, the stick can be moved left or right, allowing the servo to turn slowly and smoothly until it aligns with the commanded position. The travel time of the servo is adjustable in ten steps, ranging from "straight through" (where the controller is inactive) to approximately 30 seconds, with actual times depending on the transmitter's frame rate. Connections are made via a flying lead to the receiver and a PCB-mounted connector to the servo. This unit utilizes a PICAXE microcontroller, minimizing the parts count due to software control. A prototype unit is built on the readily available PICAXE project board AXE021, and the circuit diagram reflects this setup. If constructed on strip board, the 3.5mm stereo jack socket for programming the PIC via a serial link from a PC can be omitted, along with the programming link LK1. However, resistors R1 and R2 must remain to prevent the serial input from floating, which could cause the PICAXE to mistakenly enter reprogramming mode. R1 and R2 can be replaced with a single 33K resistor. The LED, which is a red/green bi-color device, flickers at the transmitter's frame rate to indicate operation: it flickers green when the servo is aligned with the commanded position and red while moving to a new position. In "straight through" mode, the LED displays a solid green light. If the input signal is lost (e.g., due to transmitter range issues), the LED flashes red once per second, and the servo returns to its neutral position. The LED also provides a long red flash at each step of the slew rate adjustment pot, allowing easy determination of the selected "slow" setting. The circuit diagram can be viewed in a resizable pop-up window for better visibility. The PICAXE 08M chip is preferred over the basic 08 version to enable an internal oscillator set to 8MHz, allowing a pulse-width resolution of 5 microseconds. This facilitates a 1 millisecond traverse from end to end in 200 steps, resulting in smooth operation. After verifying the presence of the input signal, the program enters the main loop, monitoring the slew rate adjustment pot and switching to "straight through" mode if necessary. The input pulse width (commanded servo position) is compared with the actual servo position. If a discrepancy exists, the servo is moved one 5 microsecond step toward the desired position, and the program returns to the main loop. After several iterations at the transmitter's nominal 20-millisecond frame rate, the servo reaches the commanded position, and the output pulse width is continuously asserted to maintain the servo's position. The slew rate adjustment pot determines the number of iterations through the 20-millisecond main loop before adjusting the servo position, enabling long-duration traverses.

The servo controller circuit is designed to enhance the performance of proportional servos in applications requiring precise and smooth motion control. The adjustment of the slew rate allows users to tailor the responsiveness of the servo to their specific needs, making it particularly useful in applications such as model boats where rapid movements can be undesirable. The use of a PICAXE microcontroller simplifies the design, allowing for a compact and efficient solution with minimal components. The bi-color LED serves multiple functions, providing real-time feedback on the servo's status and the operational mode of the controller. This feedback mechanism is crucial for users to monitor the performance and make necessary adjustments during operation. The design also considers potential issues such as signal loss, with built-in features to return the servo to a neutral position, enhancing reliability during use. Overall, the servo controller represents a significant advancement in servo control technology, offering flexibility and precision for hobbyists and professionals alike.A "servo slower" which has now evolved into a Servo Controller. `Servo slower` units are used to reduce the slew-rate (traverse time) of proportional servos. The most common use in model boats is to control the rotation of a servo-controlled gun turret, where trying to do so by transmitter stick movement alone results in unrealistically rapid and/or jerky motion. Using a `slower`, the stick can be thrust right or left and the servo will turn slowly and smoothly until it is aligned with the position commanded by the stick. The end to end travel time of the servo is adjustable in ten steps from `straight through` - ie the `slower` is inoperative - up to approximately 30 seconds.

Actual times will vary dependent upon the transmitter frame rate. Connections are via a flying-lead to the receiver and pcb mounted connector to the servo. This unit is based on a `PICAXE` micro-controller so all the clever stuff is done in software and as a result the parts count is minimal. The photo shows a prototype unit built on the readily available PICAXE project board AXE021 and the circuit diagram reflects that situation.

Should you wish to build the unit on strip-board then the 3. 5mm stereo jack socket (used to program the PIC over a serial link from your PC) can be omitted, together with the programming link LK1. If omitting the jack socket, R1 and R2 cannot be omitted - otherwise the serial input would `float` and the PICAXE could interpret that as a signal from the PC (which it expects to be attached to this input) to enter re-programming mode.

R1 and R2 can of course be replaced by a single 33K resistor. The white-ish looking LED is in fact a red/green bi-colour device which flickers at the transmitter frame rate to show the unit is operating. It flickers green whilst the servo is in alignment with the commanded position and flickers red whilst it is slewing to a new position.

In the case of the `straight through` mode being selected then the LED shows solid green. It also flashes red once per second if the input signal is not connected or disappears (eg a transmitter range problem) in either case returning the servo to its neutral position. The LED also gives a long red flash at each `step` position as the slew rate adjustment pot is turned from end to end, so by counting the flashes it is easy to determine the `slow` setting selected.

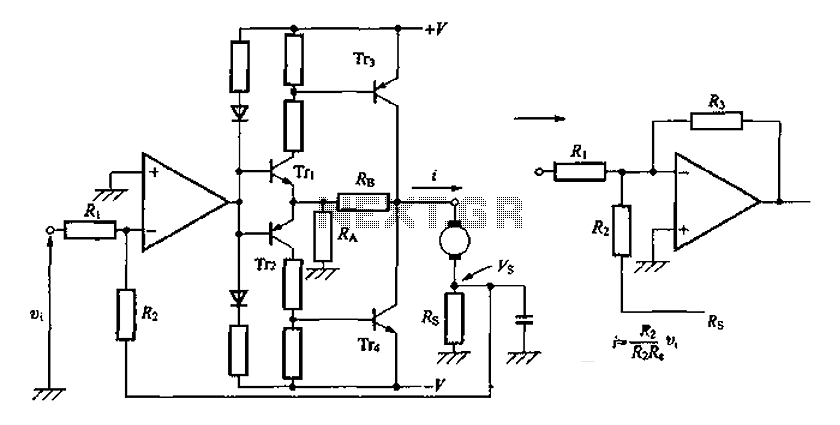

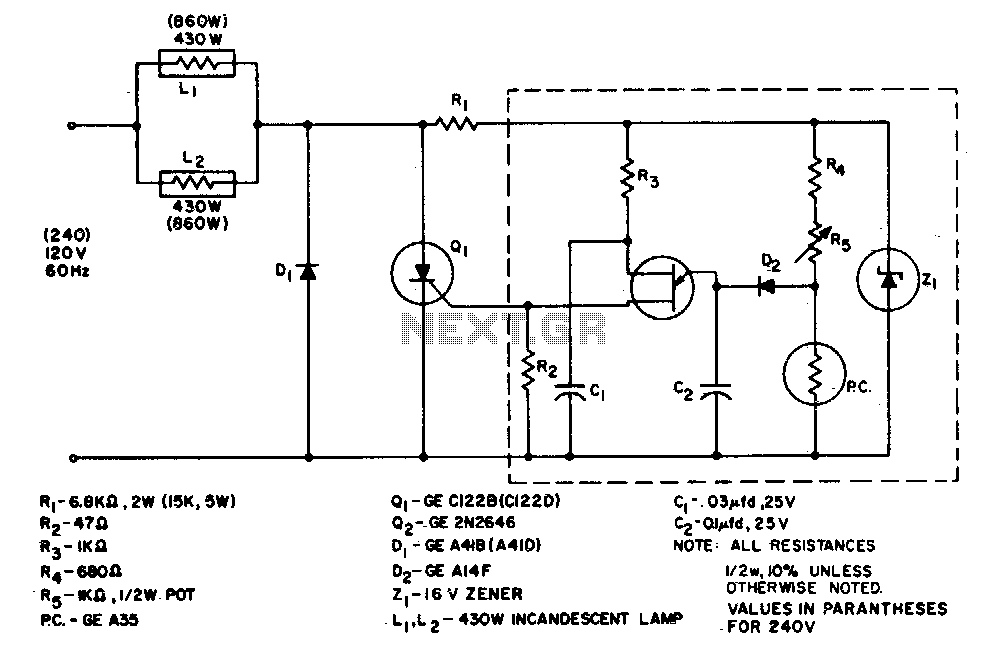

Click on the image to view the circuit diagram in a resizable pop-up window then enlarge, or maybe even maximize, the pop-up to render the diagram legible. The pop-up can be closed from its own control box, or alternatively click anywhere on the main window to close it.

The PICAXE 08M chip is used in preference to the more basic 08 part so that the internal oscillator can be set to 8Mhz operation, yielding a pulse-width resolution of 5 uSec which allows the 1 mSec traverse from end to end to be achieved in 200 steps resulting in very smooth operation. After checking for presence of the input signal the program enters the main loop where it first monitors the setting of the slew rate adjustment pot, diverting to the `straight through` mode if required.

The input pulse width (ie commanded servo position) is then checked and compared with the actual servo position. If an error exists, then the servo is moved one 5 uSec step towards the required postion and the program drops into the main loop again.

Thus after a number of steps at the transmitter`s (nominal) 20mSec frame rate the servo finally reaches the commanded position and the output pulse-width is then repeatedly asserted to hold the servo in position. The slew rate adjustment pot sets the number of times to go round the 20mSec main loop before incrementing/decrementing the servo position and in this manner quite long duration traverses can be achieved.

Each ti 🔗 External reference

The servo controller circuit is designed to enhance the performance of proportional servos in applications requiring precise and smooth motion control. The adjustment of the slew rate allows users to tailor the responsiveness of the servo to their specific needs, making it particularly useful in applications such as model boats where rapid movements can be undesirable. The use of a PICAXE microcontroller simplifies the design, allowing for a compact and efficient solution with minimal components. The bi-color LED serves multiple functions, providing real-time feedback on the servo's status and the operational mode of the controller. This feedback mechanism is crucial for users to monitor the performance and make necessary adjustments during operation. The design also considers potential issues such as signal loss, with built-in features to return the servo to a neutral position, enhancing reliability during use. Overall, the servo controller represents a significant advancement in servo control technology, offering flexibility and precision for hobbyists and professionals alike.A "servo slower" which has now evolved into a Servo Controller. `Servo slower` units are used to reduce the slew-rate (traverse time) of proportional servos. The most common use in model boats is to control the rotation of a servo-controlled gun turret, where trying to do so by transmitter stick movement alone results in unrealistically rapid and/or jerky motion. Using a `slower`, the stick can be thrust right or left and the servo will turn slowly and smoothly until it is aligned with the position commanded by the stick. The end to end travel time of the servo is adjustable in ten steps from `straight through` - ie the `slower` is inoperative - up to approximately 30 seconds.

Actual times will vary dependent upon the transmitter frame rate. Connections are via a flying-lead to the receiver and pcb mounted connector to the servo. This unit is based on a `PICAXE` micro-controller so all the clever stuff is done in software and as a result the parts count is minimal. The photo shows a prototype unit built on the readily available PICAXE project board AXE021 and the circuit diagram reflects that situation.

Should you wish to build the unit on strip-board then the 3. 5mm stereo jack socket (used to program the PIC over a serial link from your PC) can be omitted, together with the programming link LK1. If omitting the jack socket, R1 and R2 cannot be omitted - otherwise the serial input would `float` and the PICAXE could interpret that as a signal from the PC (which it expects to be attached to this input) to enter re-programming mode.

R1 and R2 can of course be replaced by a single 33K resistor. The white-ish looking LED is in fact a red/green bi-colour device which flickers at the transmitter frame rate to show the unit is operating. It flickers green whilst the servo is in alignment with the commanded position and flickers red whilst it is slewing to a new position.

In the case of the `straight through` mode being selected then the LED shows solid green. It also flashes red once per second if the input signal is not connected or disappears (eg a transmitter range problem) in either case returning the servo to its neutral position. The LED also gives a long red flash at each `step` position as the slew rate adjustment pot is turned from end to end, so by counting the flashes it is easy to determine the `slow` setting selected.

Click on the image to view the circuit diagram in a resizable pop-up window then enlarge, or maybe even maximize, the pop-up to render the diagram legible. The pop-up can be closed from its own control box, or alternatively click anywhere on the main window to close it.

The PICAXE 08M chip is used in preference to the more basic 08 part so that the internal oscillator can be set to 8Mhz operation, yielding a pulse-width resolution of 5 uSec which allows the 1 mSec traverse from end to end to be achieved in 200 steps resulting in very smooth operation. After checking for presence of the input signal the program enters the main loop where it first monitors the setting of the slew rate adjustment pot, diverting to the `straight through` mode if required.

The input pulse width (ie commanded servo position) is then checked and compared with the actual servo position. If an error exists, then the servo is moved one 5 uSec step towards the required postion and the program drops into the main loop again.

Thus after a number of steps at the transmitter`s (nominal) 20mSec frame rate the servo finally reaches the commanded position and the output pulse-width is then repeatedly asserted to hold the servo in position. The slew rate adjustment pot sets the number of times to go round the 20mSec main loop before incrementing/decrementing the servo position and in this manner quite long duration traverses can be achieved.

Each ti 🔗 External reference