Stepper Motor Project

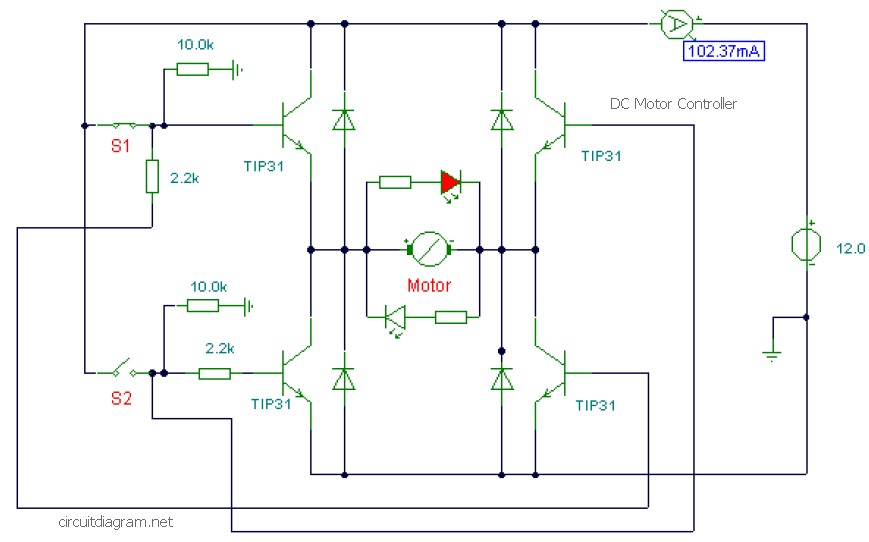

The microcontroller board is displayed (top left/green board) alongside the auxiliary board (bottom left/brown board) and two geared Hurst stepper motors. In this view, the programming jumper is located in the upper right area of the microcontroller board, while power is supplied at the lower right. The infrared (IR) sensor is positioned in the upper left, adjacent to a yellow LED. The stepper motors connect to two six-pin headers on the left side of the auxiliary board, as seen below. The activation switch, which moves the bridge up or down, connects at the bottom center, and the sound unit or other accessories connect through the screw terminals on the bottom left. When the programming jumper is installed, the unit enters program mode, allowing control via a TV remote control unit. The example uses a Philips CL015 remote, programmed to emulate a Sony remote. Ensure that the programming jumper is placed on the two jumper pins on the green microcontroller board, enabling the remote control unit to operate the motors. Input a four-digit number of degrees, such as 0720 for two rotations (720 degrees); note that the LED will flash each digit as it is entered, and allow time for each digit to flash before entering the next. Pressing the UP/DOWN button will move the motors the specified number of degrees, with the first press moving the motors clockwise (CW) and the second press moving them counterclockwise (CCW). It is important to note that if power is lost while the bridge is elevated, the unit will retain the state of being up, and the next press will lower the bridge. However, if power is lost during an up or down operation, the controller will not know the position of the bridge, necessitating a reset using the remote control unit. To reset, install the programming jumper and use the 1-6 keys to move the bridge to either the bottom or top position before restarting. For testing, connect the unit as follows: the gray wires on the left connect to the Program/Operate toggle switch. In the program position, the remote control can adjust settings and align the motors. In the operate setting, the push button (located at the end of the blue/white wires) activates the motors to move either up or down. The blue/white wires terminate in a small plug that connects to the board next to the black screw terminal connector. The red/white wires in the lower left connect to a power supply, while the two pairs of black/white wires are designated for the normally open (NO) contacts on the relay, connecting through the two sets of screw terminals marked NO.

The microcontroller board serves as the central control unit for the entire system, coordinating the operation of the stepper motors and interfacing with external components such as the IR sensor and remote control. The programming jumper is a critical component that allows the unit to switch between program mode and operational mode, enabling flexibility in control methods. The inclusion of the IR sensor enhances user interaction by allowing remote control functionality, which is particularly useful for applications requiring precise motor movements.

The stepper motors utilized in this design are geared Hurst stepper motors, which provide accurate positioning and control over movement, making them suitable for applications where precise angular displacement is required. The connection of the motors to the six-pin headers ensures a reliable interface for power and control signals.

The activation switch plays a pivotal role in the system, providing a manual method to control the bridge's position, while the sound unit or other accessories can be integrated through the screw terminals, allowing for further expansion of system capabilities.

In operational mode, the toggle switch allows for straightforward activation of the motors via a push button, simplifying user interaction. The system's design also incorporates safety features, such as the ability to retain the last known position of the bridge in case of power loss, which minimizes potential damage or operational issues.

Overall, this microcontroller-based system is designed for versatility and ease of use, making it suitable for various applications requiring controlled movement and remote operation.The microcontroller board is shown (top left/green board) along with the auxiliary board (bottom left / brown board) and the two geared Hurst stepper motors. In this view of the microcontroller board the programming jumper is in the upper right area. Power is applied in the lower right. The IR sensor is in the upper left next to the yellow LED. The stepper motors connect to the two six pin headers on the left side of the second board, seen below. The activation switch (which moves the bridge up or down) connects at the bottom center and the sound unit or other accessory connect via the screw terminals on the bottom left.

When the programming jumper is in place the unit is in program mode and functions can be controlled by the TV remote control unit. The unit used in this example is a Philips CL015 that is programmed to emulate a Sony remote 1. Make sure the programming jumper is on the two jumper pins on the green microcontroller board. This allows the remote control unit to operate the motors 2. Type a 4 digit number of degrees, for example 0720 for 2 rotations (720 degrees) - note that the LED flashes out each digit as it is entered - please allow time for each digit to flash out before entering the next digit.

Pressing the UP/DOWN button will move the motors the programmed number of degrees. The first press of UP/DOWN moves the motors CW. The second press moves the CCW. Note. If power is lost while the bridge is up the unit will remember that is was up and the next press will put the bridge down. If power is lost in the middle of an up or down operation the bridge controller will not know where the bridge was stopped and the unit must be reset by with the remote control unit - (install the programming jumper and use the 1-6 keys (as above) to move the bridge to the bottom or top position before restarting.

Connect the unit as below for testing. The grey wires on the left go to the Program / Operate toggle switch. In the program position the remote control can change setting and align the motors. In the Operate setting the push button (at the end of the blue/white wires) activates the motors either up or down. Note that the blue / white wires terminate in a small plug that goes into the board next to the black screw terminal connector.

The red/white wires in the lower left terminate in a power connector that goes to the power supply. The two pairs of black / white wires are for the NO contacts on the relay. They connect via the two sets of screw terminals marked NO. 🔗 External reference

The microcontroller board serves as the central control unit for the entire system, coordinating the operation of the stepper motors and interfacing with external components such as the IR sensor and remote control. The programming jumper is a critical component that allows the unit to switch between program mode and operational mode, enabling flexibility in control methods. The inclusion of the IR sensor enhances user interaction by allowing remote control functionality, which is particularly useful for applications requiring precise motor movements.

The stepper motors utilized in this design are geared Hurst stepper motors, which provide accurate positioning and control over movement, making them suitable for applications where precise angular displacement is required. The connection of the motors to the six-pin headers ensures a reliable interface for power and control signals.

The activation switch plays a pivotal role in the system, providing a manual method to control the bridge's position, while the sound unit or other accessories can be integrated through the screw terminals, allowing for further expansion of system capabilities.

In operational mode, the toggle switch allows for straightforward activation of the motors via a push button, simplifying user interaction. The system's design also incorporates safety features, such as the ability to retain the last known position of the bridge in case of power loss, which minimizes potential damage or operational issues.

Overall, this microcontroller-based system is designed for versatility and ease of use, making it suitable for various applications requiring controlled movement and remote operation.The microcontroller board is shown (top left/green board) along with the auxiliary board (bottom left / brown board) and the two geared Hurst stepper motors. In this view of the microcontroller board the programming jumper is in the upper right area. Power is applied in the lower right. The IR sensor is in the upper left next to the yellow LED. The stepper motors connect to the two six pin headers on the left side of the second board, seen below. The activation switch (which moves the bridge up or down) connects at the bottom center and the sound unit or other accessory connect via the screw terminals on the bottom left.

When the programming jumper is in place the unit is in program mode and functions can be controlled by the TV remote control unit. The unit used in this example is a Philips CL015 that is programmed to emulate a Sony remote 1. Make sure the programming jumper is on the two jumper pins on the green microcontroller board. This allows the remote control unit to operate the motors 2. Type a 4 digit number of degrees, for example 0720 for 2 rotations (720 degrees) - note that the LED flashes out each digit as it is entered - please allow time for each digit to flash out before entering the next digit.

Pressing the UP/DOWN button will move the motors the programmed number of degrees. The first press of UP/DOWN moves the motors CW. The second press moves the CCW. Note. If power is lost while the bridge is up the unit will remember that is was up and the next press will put the bridge down. If power is lost in the middle of an up or down operation the bridge controller will not know where the bridge was stopped and the unit must be reset by with the remote control unit - (install the programming jumper and use the 1-6 keys (as above) to move the bridge to the bottom or top position before restarting.

Connect the unit as below for testing. The grey wires on the left go to the Program / Operate toggle switch. In the program position the remote control can change setting and align the motors. In the Operate setting the push button (at the end of the blue/white wires) activates the motors either up or down. Note that the blue / white wires terminate in a small plug that goes into the board next to the black screw terminal connector.

The red/white wires in the lower left terminate in a power connector that goes to the power supply. The two pairs of black / white wires are for the NO contacts on the relay. They connect via the two sets of screw terminals marked NO. 🔗 External reference