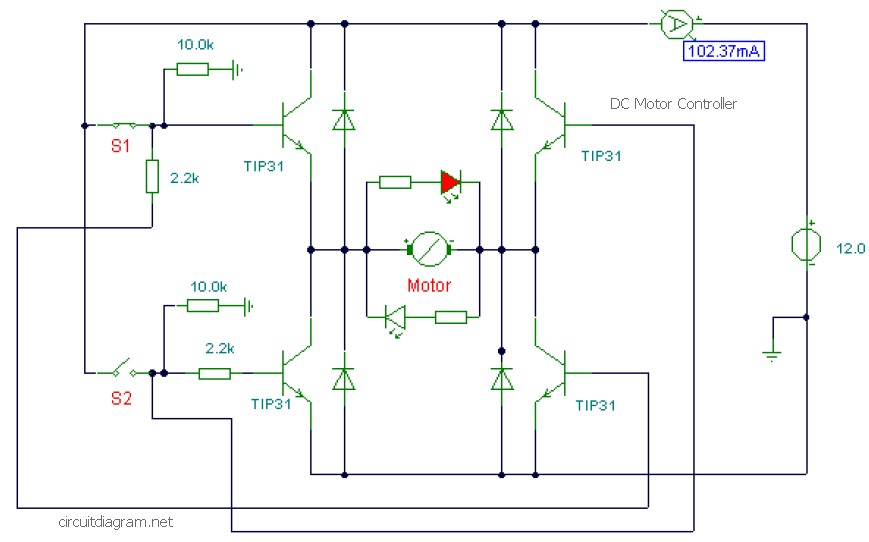

dc motor controller circuit

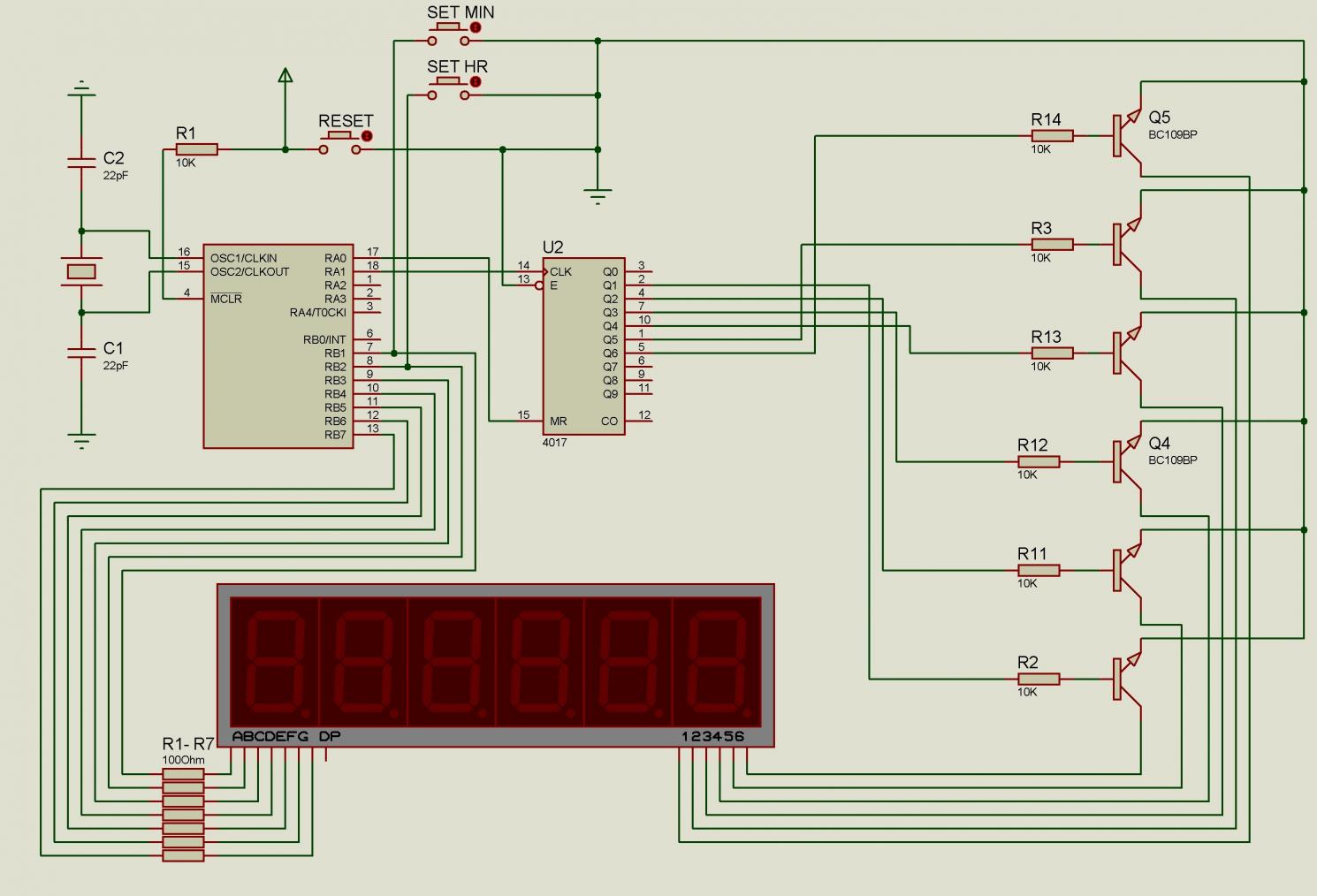

This is a DC motor controller circuit built using the TIP31 transistor based on the H-Bridge concept. The switches S1 and S2 are normally open, push-to-close buttons. The LED serves to indicate the direction of motor rotation and any common LED type can be used. The TIP31 transistors can handle up to 3A. This is a motor speed controller. The circuit diagram is built using the Maxim MAX4295, which allows for controlling the speed of motor rotation. Resistor R1 biases the potentiometer to match the input range of U1. Full counter-clockwise rotation of the potentiometer corresponds to maximum-speed reverse rotation of the motor, while mid-scale is the on position. The schematic diagram of the DC motor speed controller circuit employs two oscillators/timers connected as a Pulse Width Modulator (PWM). The timer chip used in this circuit is the dual timer/oscillator NE556, which contains two 555 timers in a single 14-pin package. The circuit also includes a low-cost water pump controller that minimizes the need for manual switching of water pumps, activating the pump when the water level in the tank falls below a certain point. Additionally, the circuit diagram for an automatic light controller utilizes the 78xx voltage regulator IC series, which provides a constant output voltage despite fluctuating input supplies when the common terminal is grounded. Any voltage above zero volts connected to the common terminal is added to the output voltage. Furthermore, the schematic diagram of an electronic motor starter circuit protects single-phase motors from voltage fluctuations and overloading. Its main function is to serve as a soft on/off electronic switch for simple operation, with a transformer stepping down the AC voltage from 230V to 15V, while diodes D1 and D2 rectify the AC voltage.

This DC motor controller circuit is designed to effectively manage the speed and direction of a DC motor using an H-Bridge configuration. The TIP31 transistors are utilized for their ability to handle currents up to 3A, making them suitable for various motor applications. The circuit's push-button switches (S1 and S2) allow for simple user interaction to change the motor's direction. The LED indicator provides visual feedback on the motor's operational state, enhancing user experience and safety.

The integration of the Maxim MAX4295 in this design facilitates precise control over the motor speed. The resistor R1 plays a critical role in ensuring that the potentiometer's output is compatible with the input requirements of the MAX4295, allowing for smooth transitions in motor speed. The PWM control implemented through the NE556 timer IC is essential for efficient motor operation, as it modulates the power supplied to the motor, thus controlling its speed effectively.

The additional features of this circuit include an automatic water pump controller, which is particularly useful in applications where water levels need to be managed without manual intervention. This system automatically activates the pump when the water level drops, ensuring that the overhead tank is refilled as necessary.

Moreover, the automatic light controller component employs the 78xx series voltage regulators to maintain a stable output voltage, which is crucial for consistent operation of the connected devices in varying input conditions. The electronic motor starter circuit adds further protection for single-phase motors, ensuring longevity and reliability by preventing damage from voltage spikes and overloads. The transformer and rectification components work together to provide a safe and controlled power supply to the motor, enhancing the overall functionality of the system.This is a DC motor controller circuit, built using transistor TIP31 based on H-Bridge concept. The switch S1 and S2 are normally open, push to close, press button switches. The LED function is to indicate the direction of motor rotation, you may use any common LED type. The TIP31 transistors capable to handle 3A. This is a motor speed controller circuit diagram built based Maxim MAX4295. This with this circuit you will be able to control the speed of motor rotation. Resistor R1 biases the potentiometer to match the input range of U1. Full counter-clockwise rotation of the pot corresponds to maximum-speed reverse rotation of the motor. Mid-scale on. This is the schematic diagram of DC motor speed controller circuit. The circuit applies two oscillators/timers which are connected as a Pulse Width Modulator (PWM). The timer chip which applied in this circuit will be an nmos dual timer/oscillator NE556. This timer IC has two 555 timers in a single 14-pin IC package. One 555. Here the circuit diagram of low cost water pump controller. The automatic pump controller minimizes the need for any manual switching of water pumps installed for the functionality of pumping water from a reservoir to an overhead tank.

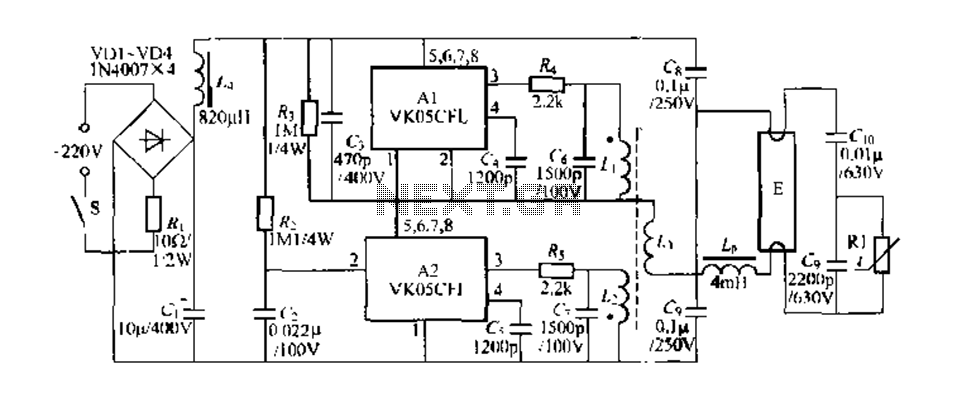

It instantly switches on the pump once the water level within the tank falls below a. This is the circuit diagram of automatic light controller which use 78xx voltage regulator IC series. The voltage regulator ICs deliver a constant output voltage, as against a extensively fluctuating input supply, when the common terminal is grounded.

Any voltage about zero volt (ground) interconnected within the common terminal is added to the output voltage. . The above diagram is the schematic diagram of an electronic motor starter circuit. This motor starter protects singlephase motors against voltage fluctuations and overloading. Its salient function is a soft on/off electronic switch for simple operation. The transformer steps down the AC voltage from 230V to 15V. Diodes D1 and D2 rectify the AC voltage. 🔗 External reference

This DC motor controller circuit is designed to effectively manage the speed and direction of a DC motor using an H-Bridge configuration. The TIP31 transistors are utilized for their ability to handle currents up to 3A, making them suitable for various motor applications. The circuit's push-button switches (S1 and S2) allow for simple user interaction to change the motor's direction. The LED indicator provides visual feedback on the motor's operational state, enhancing user experience and safety.

The integration of the Maxim MAX4295 in this design facilitates precise control over the motor speed. The resistor R1 plays a critical role in ensuring that the potentiometer's output is compatible with the input requirements of the MAX4295, allowing for smooth transitions in motor speed. The PWM control implemented through the NE556 timer IC is essential for efficient motor operation, as it modulates the power supplied to the motor, thus controlling its speed effectively.

The additional features of this circuit include an automatic water pump controller, which is particularly useful in applications where water levels need to be managed without manual intervention. This system automatically activates the pump when the water level drops, ensuring that the overhead tank is refilled as necessary.

Moreover, the automatic light controller component employs the 78xx series voltage regulators to maintain a stable output voltage, which is crucial for consistent operation of the connected devices in varying input conditions. The electronic motor starter circuit adds further protection for single-phase motors, ensuring longevity and reliability by preventing damage from voltage spikes and overloads. The transformer and rectification components work together to provide a safe and controlled power supply to the motor, enhancing the overall functionality of the system.This is a DC motor controller circuit, built using transistor TIP31 based on H-Bridge concept. The switch S1 and S2 are normally open, push to close, press button switches. The LED function is to indicate the direction of motor rotation, you may use any common LED type. The TIP31 transistors capable to handle 3A. This is a motor speed controller circuit diagram built based Maxim MAX4295. This with this circuit you will be able to control the speed of motor rotation. Resistor R1 biases the potentiometer to match the input range of U1. Full counter-clockwise rotation of the pot corresponds to maximum-speed reverse rotation of the motor. Mid-scale on. This is the schematic diagram of DC motor speed controller circuit. The circuit applies two oscillators/timers which are connected as a Pulse Width Modulator (PWM). The timer chip which applied in this circuit will be an nmos dual timer/oscillator NE556. This timer IC has two 555 timers in a single 14-pin IC package. One 555. Here the circuit diagram of low cost water pump controller. The automatic pump controller minimizes the need for any manual switching of water pumps installed for the functionality of pumping water from a reservoir to an overhead tank.

It instantly switches on the pump once the water level within the tank falls below a. This is the circuit diagram of automatic light controller which use 78xx voltage regulator IC series. The voltage regulator ICs deliver a constant output voltage, as against a extensively fluctuating input supply, when the common terminal is grounded.

Any voltage about zero volt (ground) interconnected within the common terminal is added to the output voltage. . The above diagram is the schematic diagram of an electronic motor starter circuit. This motor starter protects singlephase motors against voltage fluctuations and overloading. Its salient function is a soft on/off electronic switch for simple operation. The transformer steps down the AC voltage from 230V to 15V. Diodes D1 and D2 rectify the AC voltage. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713