the monitoring systems of railway level crossing of mining area of Atmega128 one-chip computer and GPRS

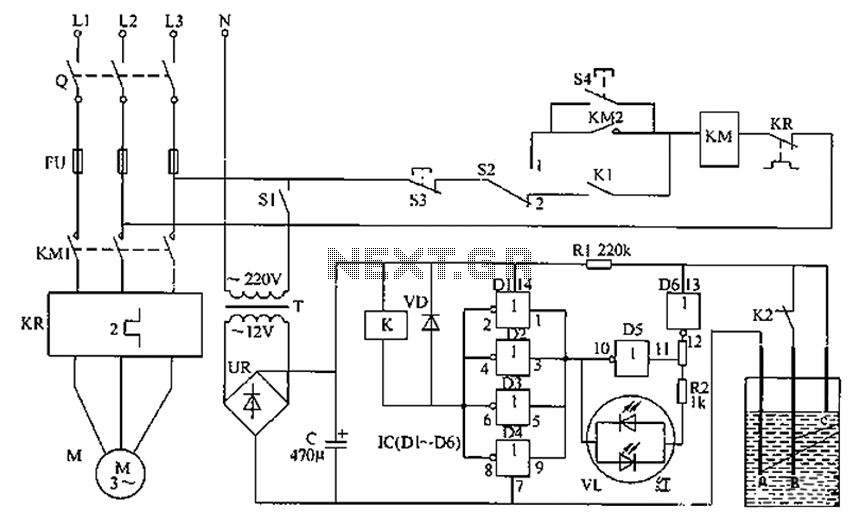

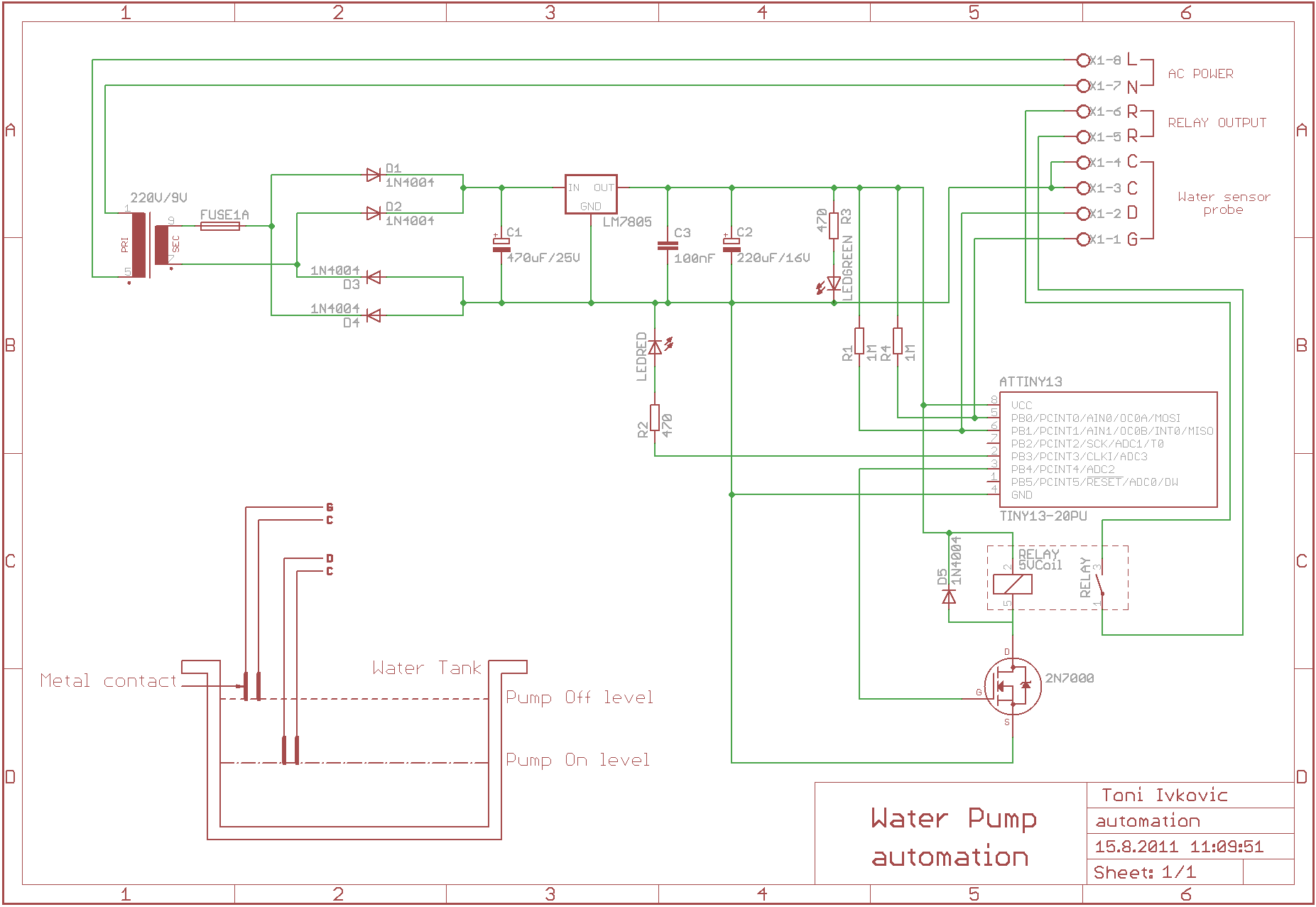

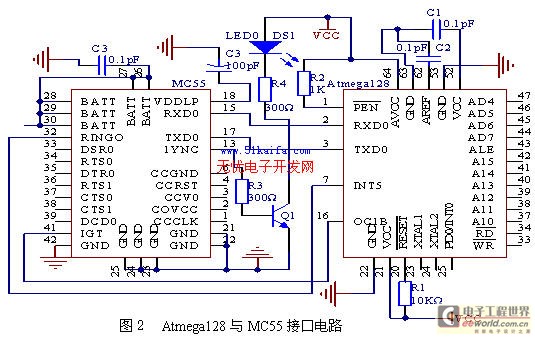

The mine railway connects the national railways and intermediate links of the mining area, serving as an important component of the railway transport network. Statistics indicate that the Chinese mine railway extends over 20,000 kilometers, with numerous road junctions typically distributed along the route. These road junctions are primarily located within mining enterprises, far from urban areas, and are numerous, dispersed, and situated at considerable distances from one another. Additionally, various transport modes in the mining area intersect, leading to significant vehicle and pedestrian traffic, which creates challenges for the safety management of the mine railway. To assist administrative departments in the mining area in monitoring safety conditions effectively and accurately, this text proposes a monitoring system designed around the Atmega128 microcontroller and MC55 module. The system aims to automate, digitize, and network the management of railway level crossings, ensuring safe interactions between mining operations and normal production activities, while also enhancing economic benefits for mining enterprises. The overall system comprises a control center for road junctions, which can be functionally divided into five parts: signal collection, road junction management, signal transmission, and the control center. A simplified block diagram illustrates a typical road junction system. The signal collection component is primarily responsible for gathering train approach and departure signals to facilitate automated guard-rail operation. Currently, the system employs various methods such as vibration pickups, radio frequency sensors, GPS, ARM, GPRS, video monitoring aids, and pedal switches to detect vehicle signals, each with its advantages and disadvantages. The signal collection subsystem consists of four magnetoelectric sensors positioned on either side of the road junction. When a train approaches, the sensors detect the train's presence and relay the signal to the Atmega128 microcontroller via an amplifying circuit and an A/D conversion circuit. The road junction management component includes auditory and visual alarms and a boom barrier, which provide guidance to trains and alert drivers and pedestrians of approaching vehicles. An automatic control box at the road junction can be operated remotely from the monitoring control center or manually by on-site personnel. The alarm system comprises a stereo circuit board and a barrel-type loudspeaker, designed to alert drivers and pedestrians to traffic conditions. The magnetoelectric sensors are situated 500 meters from the road junction, measuring incoming vehicle signals and transmitting them to the Atmega128 microcontroller within the automatic control box via copper wire. The MC55 module facilitates signal transmission to the control center of the mining area through GPRS and network connections. The data collected by the microcontroller is processed and analyzed at the control center using a PC, which plays a crucial role in monitoring the operational status of each road junction.

The proposed railway level crossing monitoring system is designed to enhance the safety and efficiency of mine railway operations. The integration of advanced sensors and microcontroller technology allows for real-time monitoring and management of train movements and road junction activities. The use of magnetoelectric sensors provides accurate detection of train presence, while the combination of auditory and visual alerts ensures that both vehicle drivers and pedestrians are adequately warned of approaching trains. The system's capability for remote monitoring and control enhances its operational flexibility, allowing for prompt responses to potential safety hazards.

Furthermore, the networked aspect of the system facilitates data sharing and analysis, enabling administrative departments to identify trends and make informed decisions regarding safety management. The comprehensive design of the monitoring system not only addresses the immediate safety concerns associated with railway crossings but also contributes to the overall efficiency and economic viability of mining operations. By ensuring the safe passage of trains and minimizing the risk of accidents at road junctions, the system supports the seamless integration of mining activities with the broader transport network.The mine railway connects the national railways and intermediate links of the mining area, it is the important constituent element of the transport network of the railway. Relevant materials statistics show, the Chinese mine railway exceeds 20, 000 kilometers and its adjacent place along the line is usually distributed in a plurality of road juncti

ons at present. Because the road junction is mostly distributed inside the mine enterprises far away from urban area, and it is in large quantity, disperse and the distance between road junction is long, in addition, mining area of different transport means to cross homework, vehicle and stationary flow of person, make a oral safety management of mine railway become very overhanging problem. In order to make the administrative departments of mining area at all levels grasp each oral security situation in time, accurately, this text regards Atmega128 and MC55 as the core, design the monitoring system of a set of railway level crossings, realize that monitors the automation, digitization and networked of management to the railway level crossing.

This pair guarantee the intersection of mining area and normal production, improve mine enterprise economic benefits and coherent road junction vehicle, pedestrian safe and significant. The overall system is made up of control center of road junction. Divide from function, this system can be divided into collecting part of a signal, road junction part, signal transmission and sent some and 5 parts of control center of road junction.

Fig. 1 takes a road junction among them as examples, provide the overall block diagram of system after simplifying. The collecting part of the signal is used mainly for gathering train approach and leaving away the signal, offer the decision signal for taking-in and putting out guard-rail of automated implementation.

Adopt vibration pickups, radio frequency sensor in the system of road junction at present, several ways such as GPS ARM GPRS, monitoring aid of the video or pedal switch measure the car signal, they each have pluses and minuses. The collecting part of the signal is made up by 4 magnetoelectric sensors, differentiates paired location inside the rail in both sides of road junction in this system.

When it is put that the train passes this, the magnetoelectric sensor can be measured the car signal of coming, after amplifying circuit and A/D chance-over circuit, send to the one piece machine Atmega128 directly. It is 2 sets respectively that the road junction part sets up numerator, combined aural and visual alarm and boom device of road junction, used for instructing the train to reach the letter soon separately Number, sound and light alarm and carrying out and putting the pole to operate.

Set up the automatic control box in the road junction, can already be by the movements per device of remote control of PC of the centre of monitoring room of road junction of the mining area, can also be by operating personnel`s in-situ hand operation. The alarm and turns the warning light round to make up from the stereo circuit board, barrel type loudspeaker, used for reminding vehicle drivers and pedestrian traffic coming and goinging scramble for roads to take care.

Install and control the place from the road junction 500 m with magnetoelectric sensor, after it measures the car signal of coming, convey the signal to the inner one-chip computer Atmega128 of automatic control box of road junction through copper axle cable. MC55 capital equipment of signal transmission, it reach the control center of road junction of mining area through the intersection of GP RS and network transmission bale, the intersection of one-chip computer and data got to gather, made and analyse and process the data further by the control center of road junction.

The control center of road junction of mining area has one P C machine, is used mainly for receiving the data of every ro 🔗 External reference

The proposed railway level crossing monitoring system is designed to enhance the safety and efficiency of mine railway operations. The integration of advanced sensors and microcontroller technology allows for real-time monitoring and management of train movements and road junction activities. The use of magnetoelectric sensors provides accurate detection of train presence, while the combination of auditory and visual alerts ensures that both vehicle drivers and pedestrians are adequately warned of approaching trains. The system's capability for remote monitoring and control enhances its operational flexibility, allowing for prompt responses to potential safety hazards.

Furthermore, the networked aspect of the system facilitates data sharing and analysis, enabling administrative departments to identify trends and make informed decisions regarding safety management. The comprehensive design of the monitoring system not only addresses the immediate safety concerns associated with railway crossings but also contributes to the overall efficiency and economic viability of mining operations. By ensuring the safe passage of trains and minimizing the risk of accidents at road junctions, the system supports the seamless integration of mining activities with the broader transport network.The mine railway connects the national railways and intermediate links of the mining area, it is the important constituent element of the transport network of the railway. Relevant materials statistics show, the Chinese mine railway exceeds 20, 000 kilometers and its adjacent place along the line is usually distributed in a plurality of road juncti

ons at present. Because the road junction is mostly distributed inside the mine enterprises far away from urban area, and it is in large quantity, disperse and the distance between road junction is long, in addition, mining area of different transport means to cross homework, vehicle and stationary flow of person, make a oral safety management of mine railway become very overhanging problem. In order to make the administrative departments of mining area at all levels grasp each oral security situation in time, accurately, this text regards Atmega128 and MC55 as the core, design the monitoring system of a set of railway level crossings, realize that monitors the automation, digitization and networked of management to the railway level crossing.

This pair guarantee the intersection of mining area and normal production, improve mine enterprise economic benefits and coherent road junction vehicle, pedestrian safe and significant. The overall system is made up of control center of road junction. Divide from function, this system can be divided into collecting part of a signal, road junction part, signal transmission and sent some and 5 parts of control center of road junction.

Fig. 1 takes a road junction among them as examples, provide the overall block diagram of system after simplifying. The collecting part of the signal is used mainly for gathering train approach and leaving away the signal, offer the decision signal for taking-in and putting out guard-rail of automated implementation.

Adopt vibration pickups, radio frequency sensor in the system of road junction at present, several ways such as GPS ARM GPRS, monitoring aid of the video or pedal switch measure the car signal, they each have pluses and minuses. The collecting part of the signal is made up by 4 magnetoelectric sensors, differentiates paired location inside the rail in both sides of road junction in this system.

When it is put that the train passes this, the magnetoelectric sensor can be measured the car signal of coming, after amplifying circuit and A/D chance-over circuit, send to the one piece machine Atmega128 directly. It is 2 sets respectively that the road junction part sets up numerator, combined aural and visual alarm and boom device of road junction, used for instructing the train to reach the letter soon separately Number, sound and light alarm and carrying out and putting the pole to operate.

Set up the automatic control box in the road junction, can already be by the movements per device of remote control of PC of the centre of monitoring room of road junction of the mining area, can also be by operating personnel`s in-situ hand operation. The alarm and turns the warning light round to make up from the stereo circuit board, barrel type loudspeaker, used for reminding vehicle drivers and pedestrian traffic coming and goinging scramble for roads to take care.

Install and control the place from the road junction 500 m with magnetoelectric sensor, after it measures the car signal of coming, convey the signal to the inner one-chip computer Atmega128 of automatic control box of road junction through copper axle cable. MC55 capital equipment of signal transmission, it reach the control center of road junction of mining area through the intersection of GP RS and network transmission bale, the intersection of one-chip computer and data got to gather, made and analyse and process the data further by the control center of road junction.

The control center of road junction of mining area has one P C machine, is used mainly for receiving the data of every ro 🔗 External reference