TRANSISTOR MOTOR CONTROLLER

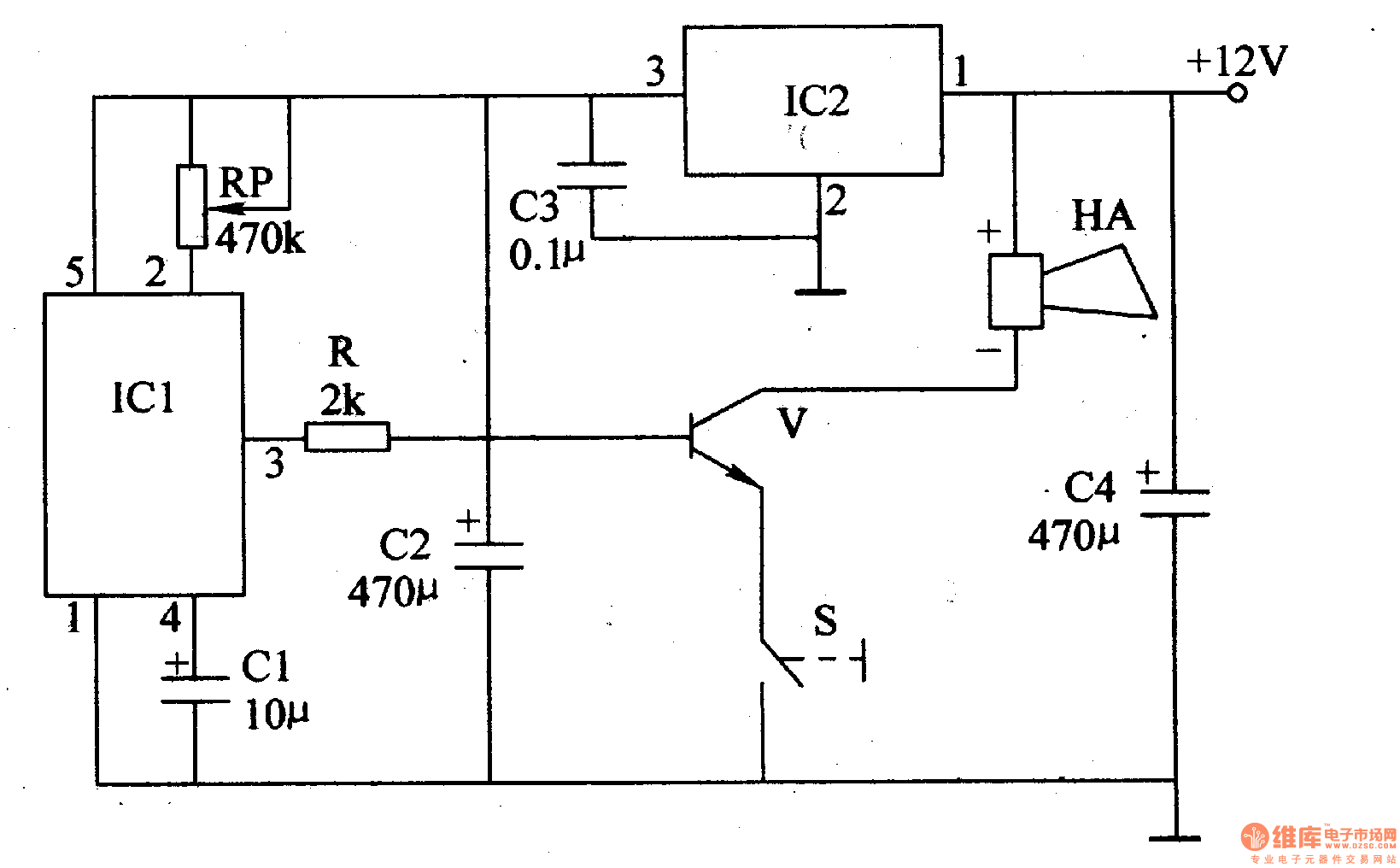

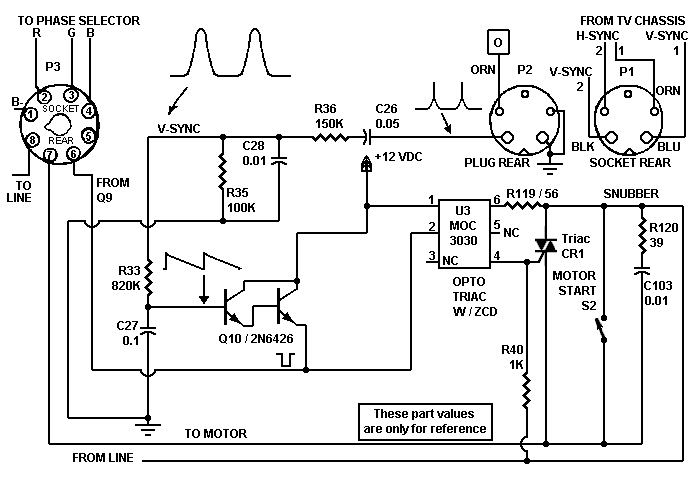

Despite the high impedance of its inputs, the Darlington transistor Q10 generates sufficient current to drive an LED. The inverted output of Q10 powers the internal LED of opto isolator U5, which, in turn, couples to the motor control triac CR1. Triac CR1 operates as a pulse-width modulator and is connected in series with the color wheel motor. This triac circuit replaces the 6BL7 dual triode tube V6 from the original Col-R-Tel circuit and also substitutes for T3, the motor control transformer. The gate voltage of the triac varies in response to signals from Q10, and the output voltage of the triac fluctuates based on the gate voltage and the line AC. Similar to the tube in the original Col-R-Tel circuit, the triac consists of two halves, with each half functioning as a silicon-controlled rectifier (SCR) that interacts with one alternation of the AC power waveform. As the input voltage to triac CR1 changes, its resistance also varies. This change in resistance directly affects the voltage drop across the motor. If the disc wedge is early, the motor runs too fast, resulting in a low input voltage to CR1. Consequently, triac CR1 increases its resistance, reducing current flow to the motor and slowing it down. Conversely, if the disc wedge is late, the motor runs too slow, leading to a high input voltage to CR1. In this case, triac CR1 decreases its resistance, allowing more current to flow to the motor, thereby increasing its speed.

The circuit utilizes a Darlington pair configuration for Q10, which provides high current gain, making it suitable for driving the LED in opto isolator U5. The opto isolator serves to electrically isolate the control signal from the motor control circuitry, ensuring that any high voltages present in the motor control section do not affect the low-voltage control circuitry. The pulse-width modulation (PWM) technique employed by triac CR1 allows for efficient control of the motor speed by adjusting the effective voltage applied to the motor based on the desired speed.

The operation of the triac is pivotal in this application as it allows for rapid switching and control over the AC waveform, which is necessary for precise motor control. The interaction of the two halves of the triac with the AC waveform enables the system to modulate power effectively. The feedback mechanism involving the disc wedge position ensures that the motor speed is continuously adjusted to maintain the desired operation, providing a responsive control system for the color wheel motor.

Overall, this circuit design exemplifies the integration of modern semiconductor devices with traditional components to enhance performance and reliability in motor control applications. The careful consideration of component interactions and feedback loops is essential for achieving optimal functionality in the system.Despite the high impedance of its inputs, Darlington Q10 develops enough current to drive an LED. The inverted output of Q10 drives opto U5`s internal LED. Opto U5 couples to motor-control triac CR1. Motor Voltage Control Triac CR1. Triac CR1 is a pulse-width modulator. CR1 connects in series with the color wheel motor. The triac circuit replaces V6, a 6BL7 dual triode tube in the original Col-R-Tel circuit. The triac also replaces T3, the Col-R-Tel motor control transformer. The triac gate voltage varies with signals from Q10. The triac output voltage varies with the gate voltage and the line AC. Like the tube in the original Col-R-Tel circuit, the triac has two halves. Each half of the triac is an SCR that interacts with one alternation of the power AC waveform. As triac CR1`s input voltage varies, the triac`s resistance changes. This resistance change increases or decreases the voltage drop across the motor. If the disc wedge is early, then the motor speed is too fast. The CR1 input voltage is low. Triac CR1 increases its resistance and reduces current flow to the motor. The motor slows down. If disc wedge is late, then the motor speed is too slow. The CR1 input voltage is high. Triac CR1 decreases its resistance and increases current flow to the motor. The motor speeds up. 🔗 External reference

The circuit utilizes a Darlington pair configuration for Q10, which provides high current gain, making it suitable for driving the LED in opto isolator U5. The opto isolator serves to electrically isolate the control signal from the motor control circuitry, ensuring that any high voltages present in the motor control section do not affect the low-voltage control circuitry. The pulse-width modulation (PWM) technique employed by triac CR1 allows for efficient control of the motor speed by adjusting the effective voltage applied to the motor based on the desired speed.

The operation of the triac is pivotal in this application as it allows for rapid switching and control over the AC waveform, which is necessary for precise motor control. The interaction of the two halves of the triac with the AC waveform enables the system to modulate power effectively. The feedback mechanism involving the disc wedge position ensures that the motor speed is continuously adjusted to maintain the desired operation, providing a responsive control system for the color wheel motor.

Overall, this circuit design exemplifies the integration of modern semiconductor devices with traditional components to enhance performance and reliability in motor control applications. The careful consideration of component interactions and feedback loops is essential for achieving optimal functionality in the system.Despite the high impedance of its inputs, Darlington Q10 develops enough current to drive an LED. The inverted output of Q10 drives opto U5`s internal LED. Opto U5 couples to motor-control triac CR1. Motor Voltage Control Triac CR1. Triac CR1 is a pulse-width modulator. CR1 connects in series with the color wheel motor. The triac circuit replaces V6, a 6BL7 dual triode tube in the original Col-R-Tel circuit. The triac also replaces T3, the Col-R-Tel motor control transformer. The triac gate voltage varies with signals from Q10. The triac output voltage varies with the gate voltage and the line AC. Like the tube in the original Col-R-Tel circuit, the triac has two halves. Each half of the triac is an SCR that interacts with one alternation of the power AC waveform. As triac CR1`s input voltage varies, the triac`s resistance changes. This resistance change increases or decreases the voltage drop across the motor. If the disc wedge is early, then the motor speed is too fast. The CR1 input voltage is low. Triac CR1 increases its resistance and reduces current flow to the motor. The motor slows down. If disc wedge is late, then the motor speed is too slow. The CR1 input voltage is high. Triac CR1 decreases its resistance and increases current flow to the motor. The motor speeds up. 🔗 External reference