Ultrasonic drilling machine circuit

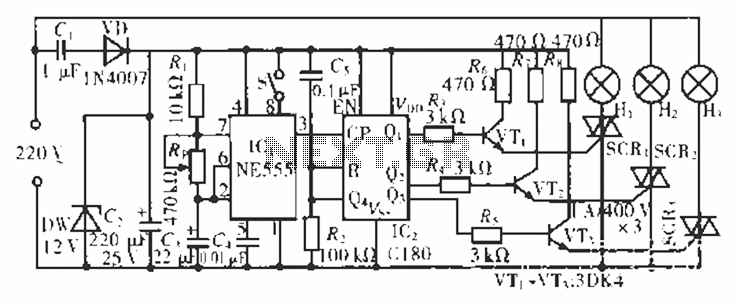

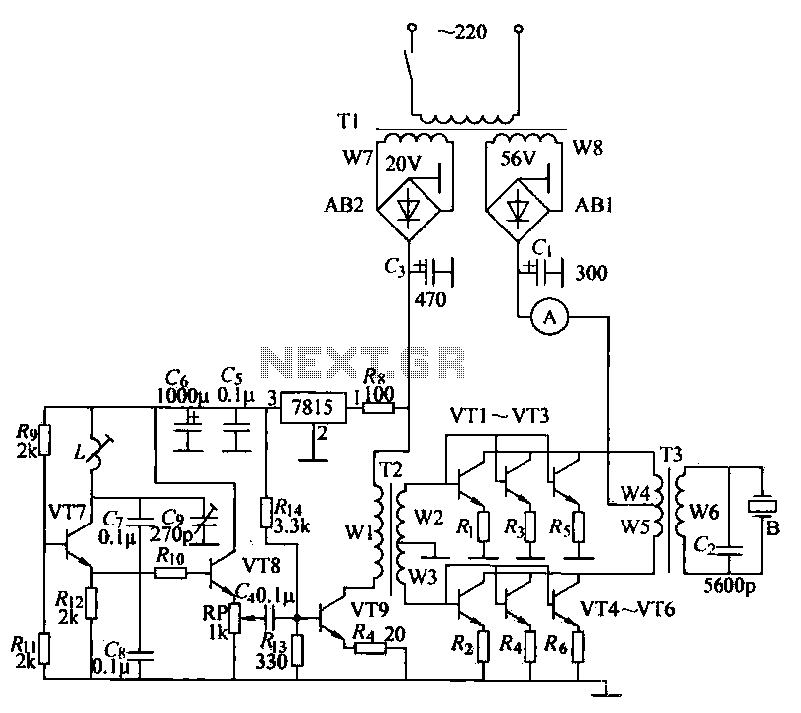

The ultrasonic drilling machine is essential machinery in the dairy industry for processing jewelry, primarily for natural stones, crystal agate, jade, and glass products. This machine is particularly effective for high-hardness materials, enabling both drilling and engraving. The following outlines the circuit of an ultrasonic drilling machine. The reader is referred to the specific components involved, including the electromechanical circuit routing, power supply circuit, ultrasonic oscillator circuit, driver amplifier, and power output circuit, as illustrated in the relevant schematic. The power circuit consists of a power switch, a power transformer, a two-way bridge rectifier circuit, an ammeter, a resistor, a three-terminal voltage regulator integrated circuit, and filter capacitors. The ultrasonic oscillator circuit includes resistors, an inductor, and capacitors, along with a transistor. The drive amplifier circuit comprises a capacitor, multiple transistors, an input transformer, and additional resistors. The power output circuit utilizes an input transformer winding, power amplifier tubes, resistors, an output transformer, a capacitor, and an ultrasonic transducer.

The operational analysis begins with the power switch, which converts AC 220V to a step-down voltage via the transformer. The transformer produces AC voltages of 20V and 56V. The 20V AC voltage is rectified and filtered, providing a near 24V DC voltage to the driver amplifier, while the 7815 voltage regulator supplies +15V for the ultrasonic oscillator's power supply. The 56V AC voltage is rectified and filtered, allowing the ammeter to provide approximately 60V DC for the power output circuit. Once powered, the ultrasonic oscillator generates oscillation signals that are amplified by transistors. The output circuit subsequently drives the power amplifier tubes, which energize the transducer. This conversion of ultrasonic vibration energy into mechanical energy facilitates the machining of workpieces, allowing for the formation of drilled holes or engraved patterns through the repetitive vibration of the milling head, typically composed of emery, submerged in water.

The ultrasonic drilling machine circuit integrates various components to create a robust system capable of handling high-hardness materials efficiently. The power supply circuit ensures stable voltage levels are maintained throughout the operation, while the ultrasonic oscillator generates the necessary frequencies for effective drilling and engraving. The driver amplifier plays a critical role in boosting the signals from the oscillator before they are sent to the power output stage, where the energy is transformed into mechanical vibrations. This intricate interplay of components ensures the machine operates optimally, providing precise and effective processing of various materials in the jewelry industry.Ultrasonic drilling machine is the dairy industry essential jewelry processing machinery, mainly for natural stones, crystal agate, jade and glass products, such as high hardness materials, drilling and engraving, the following describes an ultrasonic drilling machine circuit. For in this regard the reader is referred. (1) ultrasonic drilling electromechanical circuit routing power supply circuit, the ultrasonic oscillator circuit, a driver amplifier and power output circuit group as shown in Figure 7-72.

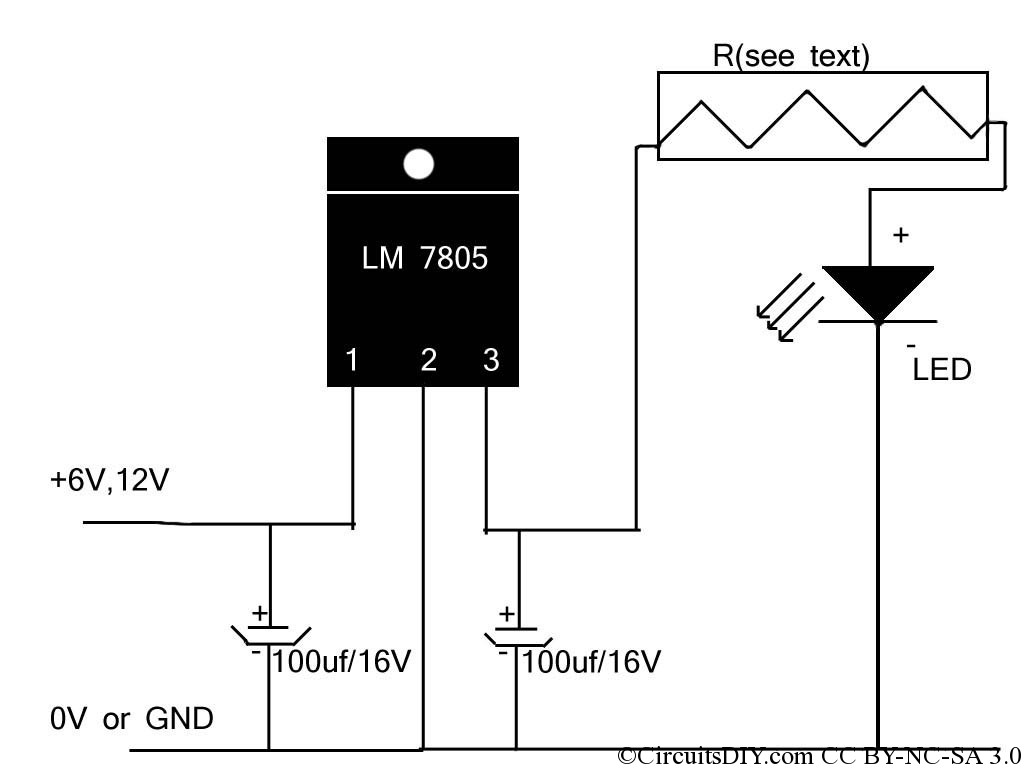

Power circuit from the power switch S, the power transformer Tl, two-way bridge rectifier circuit AI11 and AB2, ammeter A, resistance Fung, three-terminal voltage regulator integrated circuit 7815 and filter capacitors cl, c3, C, C6 composition. Ultrasonic oscillator circuit consists of resistors Island, Ru, RlZ, inductor L, and capacitor C7 ~ C9 transistor VT7 composition.

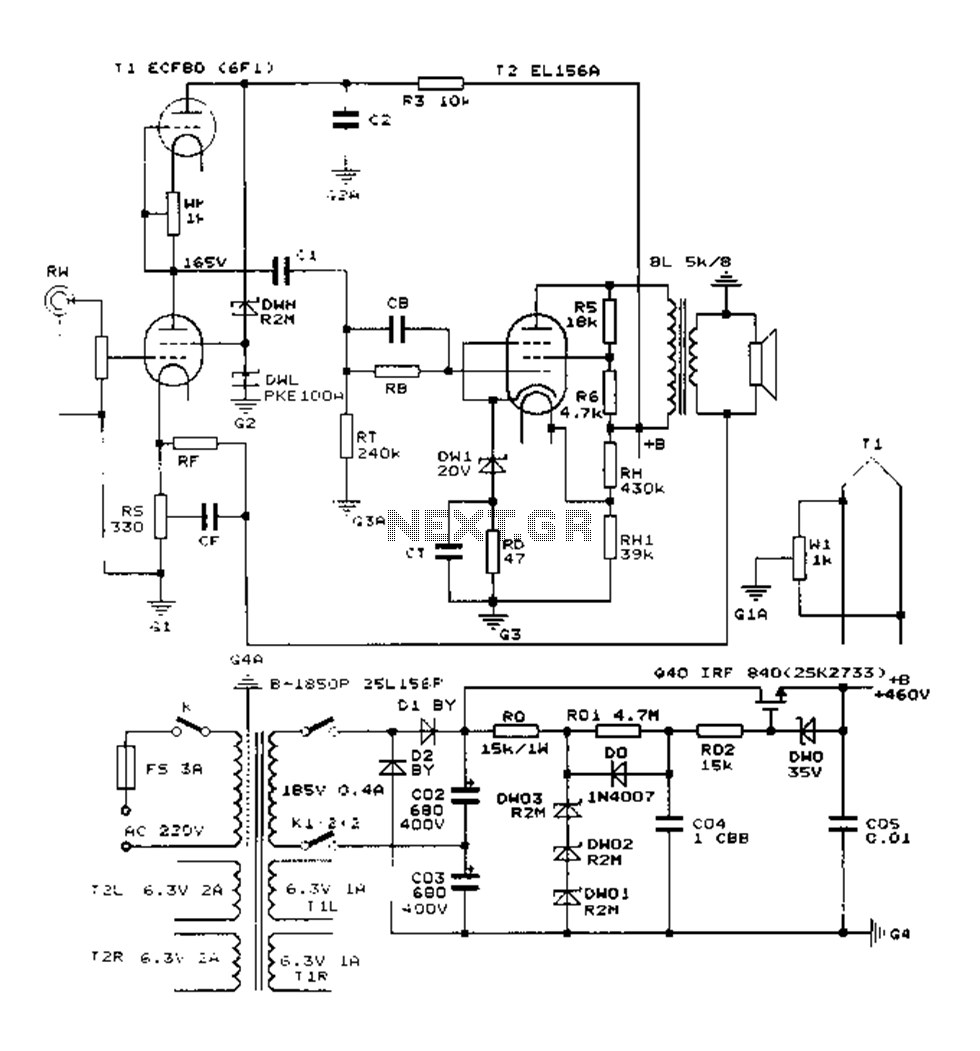

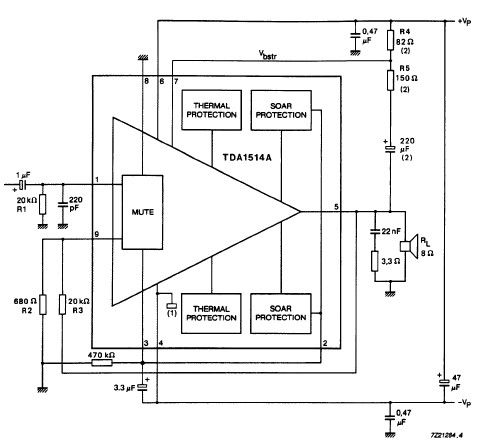

Drive amplifier circuit routing capacitor C4, transistor VT8 and VT9, input transformer 12 and a resistor Ningbo, Ria, R13, R14 components. Power output circuit by the input transformer T2 winding W2 and W3, power amplifier tube VT1, VT6. Resistance Shu, the wind, the output transformer is T3, capacitor C2 and ultrasonic transducer B dimension into.

(2) analysis of the working principle of the power switch S, AC 220V step-down voltage by Tl, Tl on winding W7 and W8 are producing an ac voltage of 20V and 56V AC voltage. AC 20V voltage through AB2 rectifier, C3 filtered all the way through winding Wl added to rr9 collector electrode, is provided near the driver amplifier 24V DC voltage; another pass 7815 ear pressure + 15V, working as an ultrasonic oscillator power supply.

AC 56V voltage after rectified by AB1 and G filter, the ammeter PA provides about 60V DC operating voltage of the power output circuit. After power the ultrasonic oscillator oscillation, the oscillation signal generated by the ultrasonic VT8, VT9 After amplification, the output circuit is coupled to the power, after power amplification VT1-VT6, and then drive the transducer through T3, the ultrasonic vibration energy into a mechanical energy vibration mill head (a generally from emery) and under water with the repeated vibration of workpiece machining parts grinding, grinding holes are formed or engraved patterns.

The operational analysis begins with the power switch, which converts AC 220V to a step-down voltage via the transformer. The transformer produces AC voltages of 20V and 56V. The 20V AC voltage is rectified and filtered, providing a near 24V DC voltage to the driver amplifier, while the 7815 voltage regulator supplies +15V for the ultrasonic oscillator's power supply. The 56V AC voltage is rectified and filtered, allowing the ammeter to provide approximately 60V DC for the power output circuit. Once powered, the ultrasonic oscillator generates oscillation signals that are amplified by transistors. The output circuit subsequently drives the power amplifier tubes, which energize the transducer. This conversion of ultrasonic vibration energy into mechanical energy facilitates the machining of workpieces, allowing for the formation of drilled holes or engraved patterns through the repetitive vibration of the milling head, typically composed of emery, submerged in water.

The ultrasonic drilling machine circuit integrates various components to create a robust system capable of handling high-hardness materials efficiently. The power supply circuit ensures stable voltage levels are maintained throughout the operation, while the ultrasonic oscillator generates the necessary frequencies for effective drilling and engraving. The driver amplifier plays a critical role in boosting the signals from the oscillator before they are sent to the power output stage, where the energy is transformed into mechanical vibrations. This intricate interplay of components ensures the machine operates optimally, providing precise and effective processing of various materials in the jewelry industry.Ultrasonic drilling machine is the dairy industry essential jewelry processing machinery, mainly for natural stones, crystal agate, jade and glass products, such as high hardness materials, drilling and engraving, the following describes an ultrasonic drilling machine circuit. For in this regard the reader is referred. (1) ultrasonic drilling electromechanical circuit routing power supply circuit, the ultrasonic oscillator circuit, a driver amplifier and power output circuit group as shown in Figure 7-72.

Power circuit from the power switch S, the power transformer Tl, two-way bridge rectifier circuit AI11 and AB2, ammeter A, resistance Fung, three-terminal voltage regulator integrated circuit 7815 and filter capacitors cl, c3, C, C6 composition. Ultrasonic oscillator circuit consists of resistors Island, Ru, RlZ, inductor L, and capacitor C7 ~ C9 transistor VT7 composition.

Drive amplifier circuit routing capacitor C4, transistor VT8 and VT9, input transformer 12 and a resistor Ningbo, Ria, R13, R14 components. Power output circuit by the input transformer T2 winding W2 and W3, power amplifier tube VT1, VT6. Resistance Shu, the wind, the output transformer is T3, capacitor C2 and ultrasonic transducer B dimension into.

(2) analysis of the working principle of the power switch S, AC 220V step-down voltage by Tl, Tl on winding W7 and W8 are producing an ac voltage of 20V and 56V AC voltage. AC 20V voltage through AB2 rectifier, C3 filtered all the way through winding Wl added to rr9 collector electrode, is provided near the driver amplifier 24V DC voltage; another pass 7815 ear pressure + 15V, working as an ultrasonic oscillator power supply.

AC 56V voltage after rectified by AB1 and G filter, the ammeter PA provides about 60V DC operating voltage of the power output circuit. After power the ultrasonic oscillator oscillation, the oscillation signal generated by the ultrasonic VT8, VT9 After amplification, the output circuit is coupled to the power, after power amplification VT1-VT6, and then drive the transducer through T3, the ultrasonic vibration energy into a mechanical energy vibration mill head (a generally from emery) and under water with the repeated vibration of workpiece machining parts grinding, grinding holes are formed or engraved patterns.