3D Laser Scanner

The red laser line gradually sweeps across the object, which in this case is a Fabuland lamb head. Behind the scanned object, two planes positioned at a 90° angle provide a reference for the scanning software. These planes are marked with regularly spaced black dots that assist in the calibration process, informing the scanning software about the webcam's characteristics, field of view, and optical distortion. The laser sweeping mechanism utilizes an NXT motor that is down-geared at a ratio of 1:2880, allowing for very slow motion. Two white rubber bands maintain tension on the gears to prevent gear lash. The NXC code allows for the adjustment of scan speed through motor speed variation and enables the laser to move at maximum speed during scan setup. Below the sweeping mechanism is a Logitech Pro 9000 webcam, which delivers high-quality images for detailed scans, although initial attempts were made with a lower-cost Trust webcam. A drawback of the Logitech webcam is the absence of a screw mounting hole, which has been addressed by adding one. The laser is powered from the NXT through a sensor port. An interface board within the cable contains a transistor to control the laser's on/off state and a series diode to reduce voltage. The schematic for the control interface indicates that D2 is a small silicon diode (1N4148) that lowers the voltage supplied to the laser, as lightly loaded NXT I/O can exceed the 4.5V maximum rating of the laser. Q1 is a small NPN transistor (BC548 or 2N3904) that controls the laser via the DIGI0 NXT I/O pin. This circuitry is similar to that used in the LEGO light sensor to control the red LED, allowing the laser to be activated as a reflected light sensor and deactivated as an ambient light sensor. A top view of the scanning bench reveals a second NXT motor that rotates the object to capture different angles. However, tilting the object to view above and below is not feasible without obstructing the camera's view of the panels behind. To address this, straight axle mounts have been replaced with assemblies containing angle connectors. The scanning program is straightforward: the user selects the scan speed and then presses the orange button to access the main scanning screen, where the laser activates. The right or left NXT keys initiate scanning in the upward or downward direction, while holding these keys for more than one second toggles to high-speed mode to pre-position the laser line before the actual scan. Pressing the orange button again switches to object rotation mode, allowing the object to be turned in 45° increments. Another press of the orange button returns to scan mode. The process is best suited for organic shapes, as geometric shapes tend to produce models with excessive triangles. For effective scanning, the laser line must be clearly visible to the camera, and the object should be lightly colored and free of patterns. If necessary, the object can be painted white using chalk spray paint or a mixture of white tempera and detergent. After scanning, careful cleaning of the object with a fine brush is required.

The described scanning system integrates several components to facilitate the capture of high-quality 3D scans of objects, particularly those with organic forms. The use of a red laser line, coupled with a precise sweeping mechanism powered by a down-geared NXT motor, allows for controlled and accurate scans. The calibration process, aided by reference planes marked with black dots, enhances the software's ability to interpret the data collected by the webcam, ensuring that the resulting scans are both detailed and reliable.

The choice of a Logitech Pro 9000 webcam is significant due to its superior image quality, which is essential for capturing the intricate details of the scanned objects. However, the absence of a mounting hole necessitates modifications to the hardware setup, highlighting the need for adaptability in engineering design. The interface board, equipped with a transistor and diode, is a critical component that ensures the laser operates within safe voltage limits, thereby preventing damage and ensuring consistent performance.

The control interface design, mirroring the functionality of existing LEGO light sensors, simplifies user interaction by allowing straightforward programming of the NXT ports. This design choice not only leverages existing technology but also reduces the learning curve for users familiar with LEGO robotics.

The scanning process itself is methodical, with the software interface guiding users through speed selection and scan initiation. The ability to rotate the object in fixed increments allows for comprehensive coverage of the subject, although the limitation of tilting poses a challenge that may require further innovation in the hardware design.

In summary, the described system exemplifies a thoughtful integration of hardware and software components to achieve high-quality 3D scanning. By addressing potential challenges and optimizing the design for specific scanning tasks, this setup demonstrates the versatility and capability of modern electronic engineering in the field of 3D modeling.The red laser line slowly sweeps the object (here a Fabuland lamb head). Behind the scanned object, two planes with a 90 ° angle provide reference to the scanning software. They are also marked with regularly spaced black dots that serve during the calibration process that inform scanning software of webcam characteristics, field of view, optics distortion. The laser sweeping mechanism. The NXT motor is down-geared by 1:2880, providing a really slow motion. The two white rubber bands maintain tension on the gears to avoid gear lash. The NXC code allows to set the scan speed through motor speed variation, and to move the laser at maximum speed during scan setup. Below the sweeping mechanism there is a Logitech Pro 9000 webcam. This high quality webcam provides very good images, thus detailed scans (though I made my first tries with a much lower cost Trust webcam).

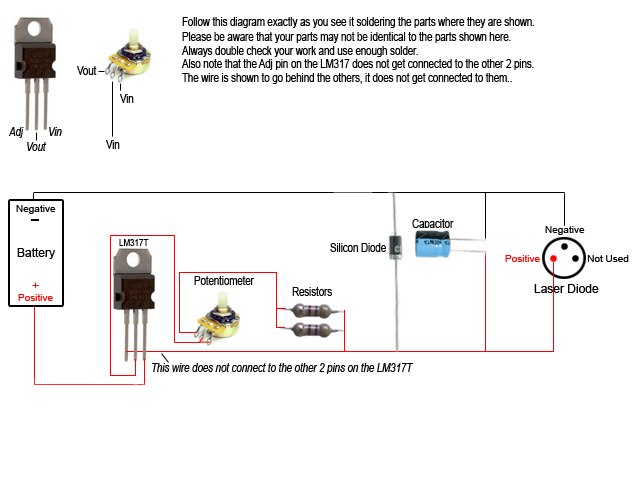

The drawback of this webcam is that it doesn` have a screw mounting hole, here is how I added one. The laser itself is powered from the NXT through a sensor port. The small interface board in the middle of the cable contains a transistor to switch the laser on/off (the same way as the LED of NXT light sensor) and a series diode to lower voltage. Schematics of the control interface. D2 is a small silicon diode (1N4148) whose purpose is to lower voltage on the laser, since lightly loaded NXT IO supply can exceed the 4.

5V maximum rating of the laser used. Q1 is a small NPN transistor (BC548, 2N3904. ) used to control laser with DIGI0 NXT I/O pin. This is the same circuitry as the one used in the LEGO light sensor to control the red LED, so the laser can be controlled the same way. Program the port as a reflected light sensor to light up the laser, and as an ambient light sensor to put it off.

Top view of the scan bench. The second NXT motor is able to rotate the object to acquire different angles of view. It would be necessary to be able to tilt the object to see above and under. Unfortunately I have not yet found a way to do this without blocking camera sight on the panels behind. So I replace straight axle mount with assemblies containing angle connectors. The program is very simple, you first choose scan speed, then pressing orange button you go to the main scanning screen.

The laser lights up. Pressing the right or left NXT key allow you to start scan in up or down direction. Pressing left or right for a more than one second toggle to high speed mode to pre-position laser line before actual scan. Pressing orange button again, you go to the object rotation mode that allows to turn the object by 45 ° increments.

Orange again comes back to scan mode. Choose the part to model. Geometrical shapes are not interesting to build through 3D scan, the models created this way contain a lot of triangles so this process is best for organic shapes, as you can see in gallery above. The laser line on the object must be clearly visible by the camera. The part must be lightly colored and without patterns. Otherwise you need to "paint" it in white color. I generally use a chalk spray paint, but white tempera with a drop of detergent works too. You`ll then need to carefully clean the object after scanning with a fine brush! install the object on the scanner and start scanning. You will need to perform scans from 🔗 External reference

The described scanning system integrates several components to facilitate the capture of high-quality 3D scans of objects, particularly those with organic forms. The use of a red laser line, coupled with a precise sweeping mechanism powered by a down-geared NXT motor, allows for controlled and accurate scans. The calibration process, aided by reference planes marked with black dots, enhances the software's ability to interpret the data collected by the webcam, ensuring that the resulting scans are both detailed and reliable.

The choice of a Logitech Pro 9000 webcam is significant due to its superior image quality, which is essential for capturing the intricate details of the scanned objects. However, the absence of a mounting hole necessitates modifications to the hardware setup, highlighting the need for adaptability in engineering design. The interface board, equipped with a transistor and diode, is a critical component that ensures the laser operates within safe voltage limits, thereby preventing damage and ensuring consistent performance.

The control interface design, mirroring the functionality of existing LEGO light sensors, simplifies user interaction by allowing straightforward programming of the NXT ports. This design choice not only leverages existing technology but also reduces the learning curve for users familiar with LEGO robotics.

The scanning process itself is methodical, with the software interface guiding users through speed selection and scan initiation. The ability to rotate the object in fixed increments allows for comprehensive coverage of the subject, although the limitation of tilting poses a challenge that may require further innovation in the hardware design.

In summary, the described system exemplifies a thoughtful integration of hardware and software components to achieve high-quality 3D scanning. By addressing potential challenges and optimizing the design for specific scanning tasks, this setup demonstrates the versatility and capability of modern electronic engineering in the field of 3D modeling.The red laser line slowly sweeps the object (here a Fabuland lamb head). Behind the scanned object, two planes with a 90 ° angle provide reference to the scanning software. They are also marked with regularly spaced black dots that serve during the calibration process that inform scanning software of webcam characteristics, field of view, optics distortion. The laser sweeping mechanism. The NXT motor is down-geared by 1:2880, providing a really slow motion. The two white rubber bands maintain tension on the gears to avoid gear lash. The NXC code allows to set the scan speed through motor speed variation, and to move the laser at maximum speed during scan setup. Below the sweeping mechanism there is a Logitech Pro 9000 webcam. This high quality webcam provides very good images, thus detailed scans (though I made my first tries with a much lower cost Trust webcam).

The drawback of this webcam is that it doesn` have a screw mounting hole, here is how I added one. The laser itself is powered from the NXT through a sensor port. The small interface board in the middle of the cable contains a transistor to switch the laser on/off (the same way as the LED of NXT light sensor) and a series diode to lower voltage. Schematics of the control interface. D2 is a small silicon diode (1N4148) whose purpose is to lower voltage on the laser, since lightly loaded NXT IO supply can exceed the 4.

5V maximum rating of the laser used. Q1 is a small NPN transistor (BC548, 2N3904. ) used to control laser with DIGI0 NXT I/O pin. This is the same circuitry as the one used in the LEGO light sensor to control the red LED, so the laser can be controlled the same way. Program the port as a reflected light sensor to light up the laser, and as an ambient light sensor to put it off.

Top view of the scan bench. The second NXT motor is able to rotate the object to acquire different angles of view. It would be necessary to be able to tilt the object to see above and under. Unfortunately I have not yet found a way to do this without blocking camera sight on the panels behind. So I replace straight axle mount with assemblies containing angle connectors. The program is very simple, you first choose scan speed, then pressing orange button you go to the main scanning screen.

The laser lights up. Pressing the right or left NXT key allow you to start scan in up or down direction. Pressing left or right for a more than one second toggle to high speed mode to pre-position laser line before actual scan. Pressing orange button again, you go to the object rotation mode that allows to turn the object by 45 ° increments.

Orange again comes back to scan mode. Choose the part to model. Geometrical shapes are not interesting to build through 3D scan, the models created this way contain a lot of triangles so this process is best for organic shapes, as you can see in gallery above. The laser line on the object must be clearly visible by the camera. The part must be lightly colored and without patterns. Otherwise you need to "paint" it in white color. I generally use a chalk spray paint, but white tempera with a drop of detergent works too. You`ll then need to carefully clean the object after scanning with a fine brush! install the object on the scanner and start scanning. You will need to perform scans from 🔗 External reference