556 controls temperature and liquid level

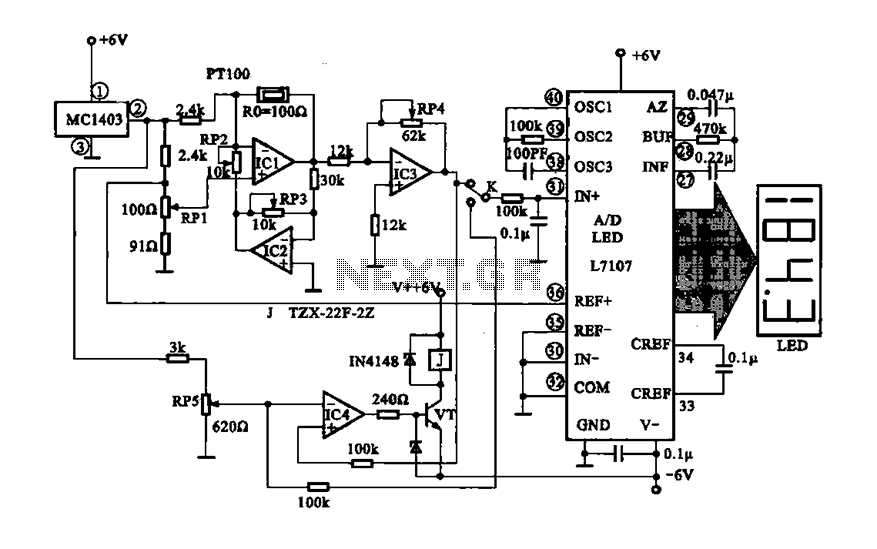

One-half of a 556 dual timer monitors the temperature of a liquid bath, controlling a heating element that maintains temperature within ±2°C over a 32° - 200°C range. The other half monitors the liquid level, disconnecting the heater when the level drops below a preset point.

The described circuit utilizes a 556 dual timer IC, which contains two independent timer circuits. The first timer is configured as a temperature controller. It employs a thermistor or other temperature-sensing device connected to one of its input pins. This allows the circuit to continuously monitor the temperature of the liquid bath. The output of this timer controls a relay or a solid-state switch that regulates the power supplied to the heating element. The design ensures that the temperature remains stable within a ±2°C range, effectively maintaining the desired thermal conditions for processes requiring precise temperature control, such as chemical reactions or material testing.

The second timer functions as a liquid level monitoring system. It utilizes a float switch or capacitive sensor to detect the liquid level within the bath. When the liquid level falls below a predetermined threshold, the output of this timer deactivates the heating element by opening the relay or switching off the solid-state device. This safety feature prevents the heating element from operating dry, which could lead to damage or hazardous conditions.

Both timers can be adjusted using external resistors and capacitors to set the desired response times and thresholds, enhancing the circuit's flexibility for various applications. The integration of these two functionalities into a single dual timer IC simplifies the design while ensuring reliable operation for maintaining optimal conditions in liquid-based processes.One-half of a 556 dual timer monitors the temperature of a liquid bath, controlling a heating element that maintains temperature within ±2°C over a 32° - 200°C range. The other half monitors the liquid level, disconnecting the heater when the level drops below a preset point.

The described circuit utilizes a 556 dual timer IC, which contains two independent timer circuits. The first timer is configured as a temperature controller. It employs a thermistor or other temperature-sensing device connected to one of its input pins. This allows the circuit to continuously monitor the temperature of the liquid bath. The output of this timer controls a relay or a solid-state switch that regulates the power supplied to the heating element. The design ensures that the temperature remains stable within a ±2°C range, effectively maintaining the desired thermal conditions for processes requiring precise temperature control, such as chemical reactions or material testing.

The second timer functions as a liquid level monitoring system. It utilizes a float switch or capacitive sensor to detect the liquid level within the bath. When the liquid level falls below a predetermined threshold, the output of this timer deactivates the heating element by opening the relay or switching off the solid-state device. This safety feature prevents the heating element from operating dry, which could lead to damage or hazardous conditions.

Both timers can be adjusted using external resistors and capacitors to set the desired response times and thresholds, enhancing the circuit's flexibility for various applications. The integration of these two functionalities into a single dual timer IC simplifies the design while ensuring reliable operation for maintaining optimal conditions in liquid-based processes.One-half of a 556 dual timer monitors the temperature of a liquid bath, controlling a heating element that maintains temperature within ±2°C over a 32° - 200°C range. The other half monitors the liquid level, disconnecting the heater when the level drops below a preset point.