6V6 6J5 Class A Vacuum Tube (Valve) Amplifier Circuit

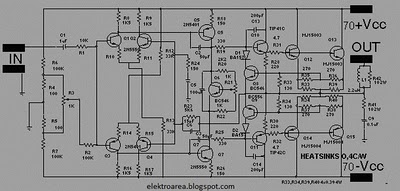

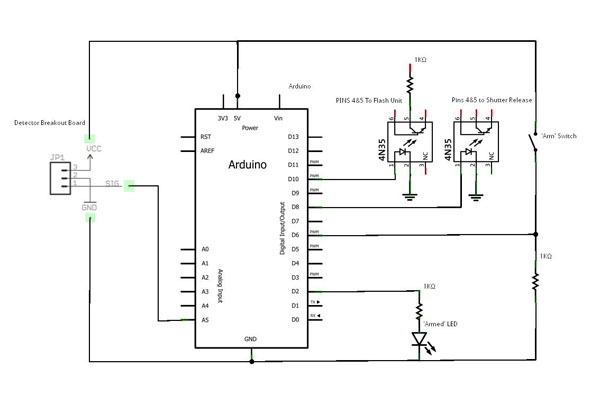

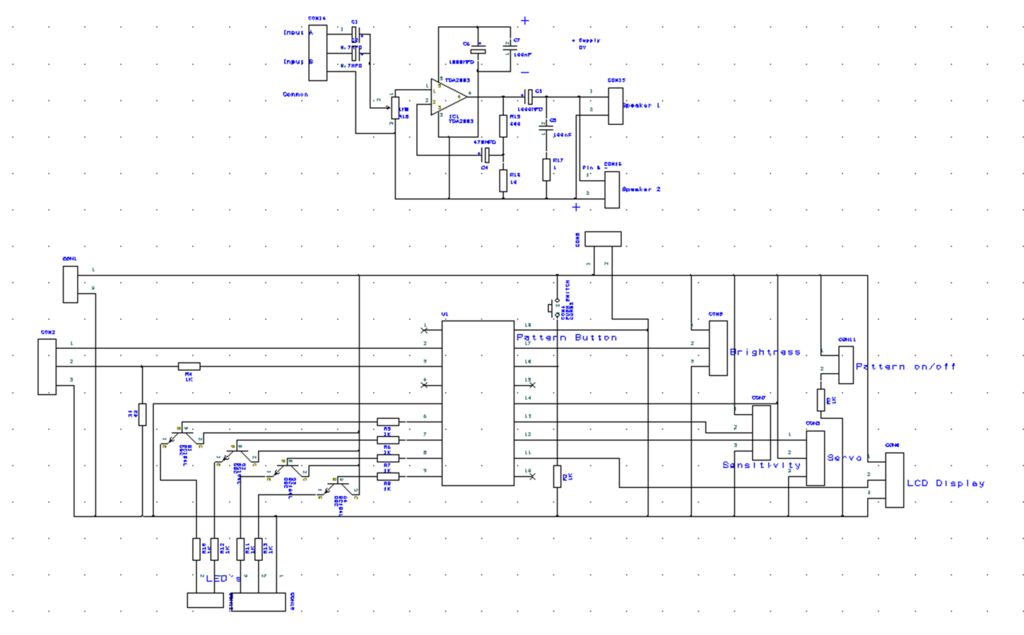

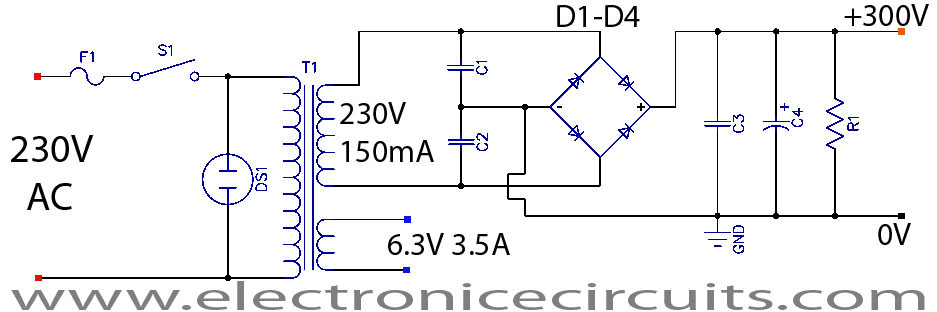

This project is a successful vacuum tube amplifier utilizing a 6V6GT output pentode configured in triode mode, producing approximately 4.5 watts of output power. The design features a single-ended audio amplifier with a resistive input network, a driver stage, and an output stage designed for an 8-ohm loudspeaker load, employing minimal passive components for biasing and coupling. The power supply is generated through full-wave diode rectification from 230 VAC using a magnetic transformer, contributing to the amplifier's quality. A key aspect of the design is the compatibility between the output tube and the output transformer (OT) for optimal impedance matching. The 6V6 tube, in triode mode, operates with an ideal load impedance of 5k ohms, while the OT is rated for 8 watts and facilitates the impedance transition from 5k primary to 8-ohm secondary, suitable for standard loudspeakers. The amplifier employs a linear power supply to generate 300VDC, with heater voltages sourced from the 6.3VAC taps on the power transformer’s secondary. The secondary winding rated at 230VAC is used for the DC supply, which includes four rectifiers, various smoothing capacitors, and resistors. Construction considerations included managing high power supply voltages, large inductive components, and elevated temperatures. An old tube amplifier chassis was repurposed, and to mitigate magnetic interference, the output transformer (OT) and power transformer (PT) were positioned at opposite ends of the chassis with their axes rotated 90 degrees apart. This arrangement reduces induction noise between the transformers while directing OT flux away from the 6V6 tube, thus avoiding interference with the sensitive preamp stage tube. Additional hum reduction measures were implemented by twisting all pairs of wires carrying AC, including filament heater wires and the PT wiring to the diode rectifier.

The vacuum tube amplifier design is characterized by its single-ended configuration, which is particularly well-suited for audio applications due to its simplicity and warm sound characteristics. The 6V6GT tube, known for its reliability and favorable sonic qualities, operates effectively in triode mode, offering reduced power output but enhanced linearity and lower distortion, making it ideal for high-fidelity audio applications.

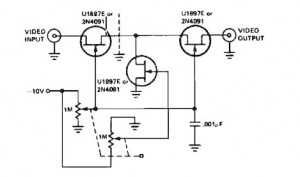

The amplifier's input stage utilizes a resistive network that ensures proper signal conditioning and impedance matching for the audio source. The driver stage amplifies the audio signal before it reaches the output stage, where the 6V6GT tube drives the loudspeaker. The output transformer plays a critical role in impedance matching, allowing the high impedance of the tube to be effectively coupled to the low impedance of the loudspeaker, maximizing power transfer and ensuring efficient operation.

The power supply design is integral to the amplifier's performance, employing full-wave rectification to convert the AC voltage into a stable DC supply. The use of smoothing capacitors is essential in filtering out ripple voltage, providing a clean power source that contributes to the overall sound quality of the amplifier. The careful selection of rectifiers and capacitors ensures that the power supply can handle the demands of the amplifier while maintaining reliability.

Construction techniques are vital in tube amplifier design, particularly regarding thermal management and electromagnetic interference. The strategic placement of transformers minimizes noise and enhances performance, while the use of twisted pairs for AC wiring reduces hum and improves overall signal integrity. This attention to detail in both design and construction results in a high-quality audio amplifier capable of delivering rich sound with minimal distortion, suitable for audiophiles and music enthusiasts alike.This is my first successful vacuum tube project. The output of this small amplifier in which a 6V6GT output pentode is connected as triode is about 4. 5 watts. This project involves a single ended audio amplifier, which consists of a resistive input network, a driver stage, and an output stage to a typical 8 ohm loudspeaker load, all the while, usi

ng a minimum of supportive passive components for biasing and coupling duties. Power-supply voltage is provided by full wave diode rectification of 230 VAC by a magnetic transformer. This design provides a quality audio amplifier. The major factor involving the design of this single ended output stage is matching an available output tube to an available output transformer (OT), which can provide the proper impedance matching.

Using typical operating parameters, the 6V6 power tube, operating in triode mode, has an ideal load impedance of 5k Ohm, and generates about 4. 5 watts of power. An OT was used, handling 8 watts and providing impedance matching from a 5k primary to an 8 ohm secondary, which is a common loudspeaker impedance.

The amplifier uses a simple linear power supply to develop 300VDC. Heater voltages are supplied directly from the 6. 3VAC taps on the secondary of the power transformer. The other secondary windings, rated at 230VAC are used for the DC supply. It consists of a 4 rectifiers, variety of smoothing capacitors and resistor. Several construction issues were considered in the building of this amplifier. High power supply voltages, large and leaky inductive components, and high temperatures are among these considerations. I used old tube amplifier chassis. Magnetic flux is expelled from the transformers as shown by the red arrows above. By placing the output transformer (OT) and power transformer (PT) at opposite ends of the chassis, and rotating their axes 90 ° from one another, induction noise from PT to OT is reduced.

Although this configuration sees flux from the OT directed at the 6V6, OT flux interference into the sensitive preamp stage tube is avoided. Beneath the chassis hum reduction is further achieved by winding all pairs of wire containing AC (filament heater wires, PT primary, and secondary wiring to the diode rectifier).

🔗 External reference

The vacuum tube amplifier design is characterized by its single-ended configuration, which is particularly well-suited for audio applications due to its simplicity and warm sound characteristics. The 6V6GT tube, known for its reliability and favorable sonic qualities, operates effectively in triode mode, offering reduced power output but enhanced linearity and lower distortion, making it ideal for high-fidelity audio applications.

The amplifier's input stage utilizes a resistive network that ensures proper signal conditioning and impedance matching for the audio source. The driver stage amplifies the audio signal before it reaches the output stage, where the 6V6GT tube drives the loudspeaker. The output transformer plays a critical role in impedance matching, allowing the high impedance of the tube to be effectively coupled to the low impedance of the loudspeaker, maximizing power transfer and ensuring efficient operation.

The power supply design is integral to the amplifier's performance, employing full-wave rectification to convert the AC voltage into a stable DC supply. The use of smoothing capacitors is essential in filtering out ripple voltage, providing a clean power source that contributes to the overall sound quality of the amplifier. The careful selection of rectifiers and capacitors ensures that the power supply can handle the demands of the amplifier while maintaining reliability.

Construction techniques are vital in tube amplifier design, particularly regarding thermal management and electromagnetic interference. The strategic placement of transformers minimizes noise and enhances performance, while the use of twisted pairs for AC wiring reduces hum and improves overall signal integrity. This attention to detail in both design and construction results in a high-quality audio amplifier capable of delivering rich sound with minimal distortion, suitable for audiophiles and music enthusiasts alike.This is my first successful vacuum tube project. The output of this small amplifier in which a 6V6GT output pentode is connected as triode is about 4. 5 watts. This project involves a single ended audio amplifier, which consists of a resistive input network, a driver stage, and an output stage to a typical 8 ohm loudspeaker load, all the while, usi

ng a minimum of supportive passive components for biasing and coupling duties. Power-supply voltage is provided by full wave diode rectification of 230 VAC by a magnetic transformer. This design provides a quality audio amplifier. The major factor involving the design of this single ended output stage is matching an available output tube to an available output transformer (OT), which can provide the proper impedance matching.

Using typical operating parameters, the 6V6 power tube, operating in triode mode, has an ideal load impedance of 5k Ohm, and generates about 4. 5 watts of power. An OT was used, handling 8 watts and providing impedance matching from a 5k primary to an 8 ohm secondary, which is a common loudspeaker impedance.

The amplifier uses a simple linear power supply to develop 300VDC. Heater voltages are supplied directly from the 6. 3VAC taps on the secondary of the power transformer. The other secondary windings, rated at 230VAC are used for the DC supply. It consists of a 4 rectifiers, variety of smoothing capacitors and resistor. Several construction issues were considered in the building of this amplifier. High power supply voltages, large and leaky inductive components, and high temperatures are among these considerations. I used old tube amplifier chassis. Magnetic flux is expelled from the transformers as shown by the red arrows above. By placing the output transformer (OT) and power transformer (PT) at opposite ends of the chassis, and rotating their axes 90 ° from one another, induction noise from PT to OT is reduced.

Although this configuration sees flux from the OT directed at the 6V6, OT flux interference into the sensitive preamp stage tube is avoided. Beneath the chassis hum reduction is further achieved by winding all pairs of wire containing AC (filament heater wires, PT primary, and secondary wiring to the diode rectifier).

🔗 External reference