AC Locomotive Auxiliary Equipment

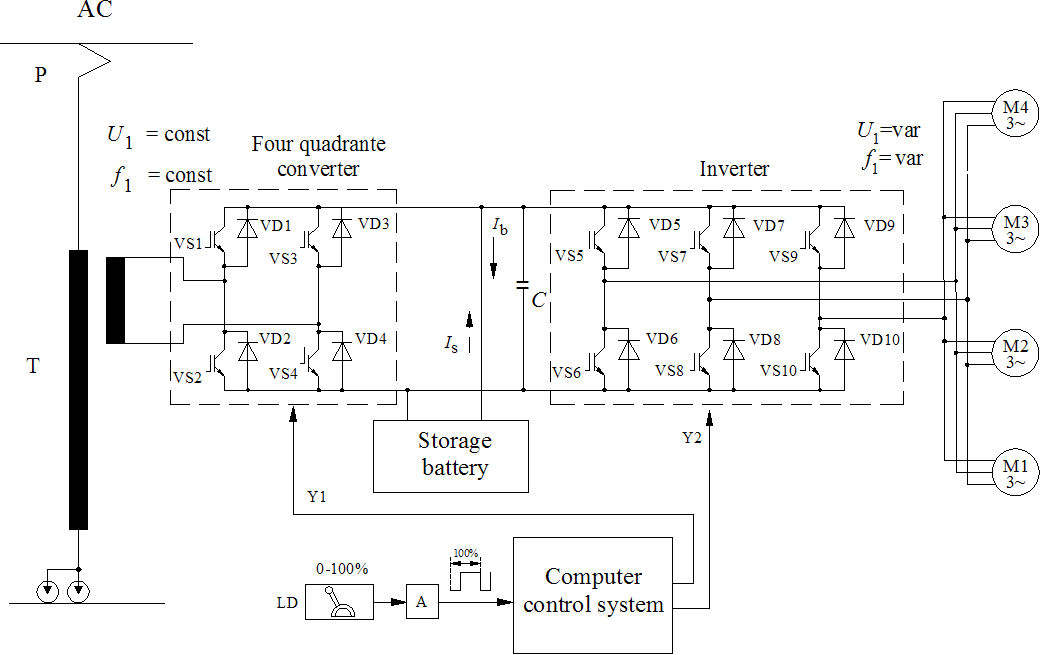

Electric locomotives derive tractive effort from traction motors, which are typically located in the bogie of the locomotive. Generally, one motor is assigned to each axle; however, some older locomotive models utilized a single traction motor to drive two axles. In addition to traction motors, electric locomotives are equipped with various other motors and equipment. These additional motors are collectively referred to as auxiliaries. This article aims to provide insight into the various auxiliary machines utilized in electric locomotives operating on the Indian Railways. To understand the necessity of these auxiliaries, it is essential to comprehend the operational mechanics of electric locomotives. A critical component of the electric locomotive is the power circuit. A brief overview of the power circuit of electric locomotives operating on the Indian Railways is provided here. The main components of the power circuit include several parts that generate significant heat during normal operation. Even when not in use, these components may still produce a nominal amount of heat. Generally, electrical equipment generates heat as a by-product of operation, but traction vehicles tend to produce more heat than usual. This increase in heat generation is attributed to the rising demand for traction vehicles. An increase in power output typically necessitates a corresponding increase in the size of the relevant equipment. However, traction vehicles face limitations in size due to "loading gauge restrictions." Consequently, the power output of locomotives must be increased indirectly without enlarging the equipment. This is achieved by "pumping" more power through the equipment while simultaneously cooling them effectively. The various auxiliaries installed for cooling and other functions in these locomotives are described below. All motors utilized are of the AC three-phase squirrel cage induction type, requiring minimal maintenance and characterized by simplicity and robustness. They are discussed concerning their relationship to the major power equipment. The transformer tank is filled with oil, serving two primary purposes: providing enhanced insulation to the transformer and its surroundings, and absorbing the heat generated within the transformer to transfer it to the transformer oil cooling radiator. The circulation of this oil is managed by the main pump (MPH). A flow valve equipped with an electrical contact is located in the oil circulation pipe. As long as the oil circulates properly, the contacts on the relay remain closed. However, if the MPH fails or ceases operation, the relay contacts open, which in turn trips the master auxiliary protection relay (Q-118) and subsequently trips the main circuit breaker (DJ) of the locomotive, thus protecting the transformer. The MPH circulates transformer oil through a radiator array positioned atop the transformer. Air is blown over the radiator by the main ventilation and radiator heater (MVRH), expelling heat from the radiator into the atmosphere. A flow detecting relay is positioned within the air stream of the MVRH. This diaphragm-type device detects airflow, pressing the diaphragm to close an electrical contact. This relay is designated as QVRH. In the event of a failure of the MVRH blower, the QVRH releases, tripping the DJ through relay Q-118. The transformer and its cooling equipment include a small vertical motor on the top left, which is the MPH, and a larger horizontal motor in the top center, which is the MVRH, with the oil cooling radiator positioned behind it. Each rectifier block is equipped with a blower, as rectifiers are semiconductor devices sensitive to temperature and require continuous cooling. The switching sequence of the MVSI blowers is configured such that unless the blowers are operational, the system cannot function effectively.

The electrical system of electric locomotives is complex and requires careful integration of various components to ensure efficient operation and safety. Each auxiliary plays a crucial role in maintaining optimal performance levels while managing the thermal output generated during operation. The design considerations include not only the thermal management systems but also the reliability of the auxiliary motors, which are designed to operate in harsh environments. The use of AC three-phase squirrel cage induction motors offers advantages in terms of durability and low maintenance requirements, which are critical for the continuous operation of electric locomotives.

Furthermore, the transformer oil cooling system is essential for preventing overheating, which can lead to equipment failure and safety hazards. The integration of flow detection relays and protective relays enhances the safety mechanisms within the power circuit, ensuring that any malfunction in the cooling system triggers an immediate response to protect the locomotive's critical components. The relationship between the various auxiliary systems and the main power circuit underscores the importance of a well-coordinated design approach in electric locomotive engineering. Overall, the operational efficiency and safety of electric locomotives depend significantly on the effective functioning of these auxiliary systems, which are meticulously designed to meet the demands of modern rail transport.Electric locos derive tractive effort from Traction Motors which are usually placed in the bogie of the locomotive. Usually one motor is provided per axle but in some older generation of locos two axles were driven by a single Traction Motor also.

However apart from Traction Motors, many other motors and equipments are provided in electric locos. These motors are collectively known as the Auxiliaries. The aim of this article is to provide an insight into the various Auxiliary Machines provided in the Electric Locos operational on the Indian Railways. But to understand the reasons why these auxiliaries are needed, it is necessary to understand the manner in which the electric locos operate.

An important part of the electric loco is the Power Circuit. A short description of the power circuit of Electric Locos operational on the Indian Railways can be seen here. The article referred to describes the main components of the Power Circuit of the Electric Locomotive comprising of the following parts: A common feature running through all the above electrical equipments is that all of these generate a lot of heat during their normal operation.

Even when they are not in use, they might generate a nominal amount of heat. Normally any electrical equipment generates heat as by-product during operation. But traction vehicles tend to generate more heat than normal. This is because day-by-day the demand on traction vehicles is increasing. But an increase in the power output more or less translates into increased size of the relevent equipments too. But a major problem with traction vehicles is that you cannot increase their size beyond a certain limit.

This is due to "Loading Guage Restrictions". Hence, the power output of the locomotives has to be increased indirectly without increasing their size. This is done by "pumping"more power through the equipments and cooling them at a suitable rate at the same time.

Hence the different auxiliaries provided for cooling and other purposes in these locos is described below. All the motors are of the AC 3 Phase squirrel cage induction type and require very little maintenance and are simple and robust.

They are described with regard to their relationship to the major power equipments The transformer tank is filled with oil which serves two purposes. It provides enhanced insulation to the transformer and its surroundings and the oil absorbs the heat generated in the transformer and takes it away to the Transformer Oil Cooling Radiator.

The circulation of this oil is carried out by the MPH. A flow valve with an electrical contact is provided in the oil circulating pipe. As long as the oil is circulating properly, the contacts on the relay remain closed. However, in case the MPH fails or stops the relay contacts open which in turn trips master auxiliary protection relay Q-118. This trips the main circuit-breaker(DJ) of the loco. Thus the transformer is protected. The MPH circulates the transformer oil through a radiator array on top of the transformer. Air is blown over the radiator by the MVRH. This discharges the heat from the radiator into the atmosphere. A flow detecting relay is provided in the air-stream of the MVRH. The flow detector is a diaphragm type device. The flow of air presses the diaphragm which closes an electrical contact. This relay is known as the QVRH. In case the MVRH blower fails the the QVRH releases and trips the DJ through the relay Q-118. The transformer and its cooling equipment. The small vertical motor on top left is the MPH and the horizontal larger motor in the top centre is the MVRH and behind it is the oil cooling radiator.

Click for a larger view. One blower is provided for each of the rectifier blocks. As rectifiers are semiconductor devices, they are very sensitive to heat and hence must be cooled continously. The switching sequence of the MVSI blowers is setup in such a way that unless the blowers are runn 🔗 External reference

The electrical system of electric locomotives is complex and requires careful integration of various components to ensure efficient operation and safety. Each auxiliary plays a crucial role in maintaining optimal performance levels while managing the thermal output generated during operation. The design considerations include not only the thermal management systems but also the reliability of the auxiliary motors, which are designed to operate in harsh environments. The use of AC three-phase squirrel cage induction motors offers advantages in terms of durability and low maintenance requirements, which are critical for the continuous operation of electric locomotives.

Furthermore, the transformer oil cooling system is essential for preventing overheating, which can lead to equipment failure and safety hazards. The integration of flow detection relays and protective relays enhances the safety mechanisms within the power circuit, ensuring that any malfunction in the cooling system triggers an immediate response to protect the locomotive's critical components. The relationship between the various auxiliary systems and the main power circuit underscores the importance of a well-coordinated design approach in electric locomotive engineering. Overall, the operational efficiency and safety of electric locomotives depend significantly on the effective functioning of these auxiliary systems, which are meticulously designed to meet the demands of modern rail transport.Electric locos derive tractive effort from Traction Motors which are usually placed in the bogie of the locomotive. Usually one motor is provided per axle but in some older generation of locos two axles were driven by a single Traction Motor also.

However apart from Traction Motors, many other motors and equipments are provided in electric locos. These motors are collectively known as the Auxiliaries. The aim of this article is to provide an insight into the various Auxiliary Machines provided in the Electric Locos operational on the Indian Railways. But to understand the reasons why these auxiliaries are needed, it is necessary to understand the manner in which the electric locos operate.

An important part of the electric loco is the Power Circuit. A short description of the power circuit of Electric Locos operational on the Indian Railways can be seen here. The article referred to describes the main components of the Power Circuit of the Electric Locomotive comprising of the following parts: A common feature running through all the above electrical equipments is that all of these generate a lot of heat during their normal operation.

Even when they are not in use, they might generate a nominal amount of heat. Normally any electrical equipment generates heat as by-product during operation. But traction vehicles tend to generate more heat than normal. This is because day-by-day the demand on traction vehicles is increasing. But an increase in the power output more or less translates into increased size of the relevent equipments too. But a major problem with traction vehicles is that you cannot increase their size beyond a certain limit.

This is due to "Loading Guage Restrictions". Hence, the power output of the locomotives has to be increased indirectly without increasing their size. This is done by "pumping"more power through the equipments and cooling them at a suitable rate at the same time.

Hence the different auxiliaries provided for cooling and other purposes in these locos is described below. All the motors are of the AC 3 Phase squirrel cage induction type and require very little maintenance and are simple and robust.

They are described with regard to their relationship to the major power equipments The transformer tank is filled with oil which serves two purposes. It provides enhanced insulation to the transformer and its surroundings and the oil absorbs the heat generated in the transformer and takes it away to the Transformer Oil Cooling Radiator.

The circulation of this oil is carried out by the MPH. A flow valve with an electrical contact is provided in the oil circulating pipe. As long as the oil is circulating properly, the contacts on the relay remain closed. However, in case the MPH fails or stops the relay contacts open which in turn trips master auxiliary protection relay Q-118. This trips the main circuit-breaker(DJ) of the loco. Thus the transformer is protected. The MPH circulates the transformer oil through a radiator array on top of the transformer. Air is blown over the radiator by the MVRH. This discharges the heat from the radiator into the atmosphere. A flow detecting relay is provided in the air-stream of the MVRH. The flow detector is a diaphragm type device. The flow of air presses the diaphragm which closes an electrical contact. This relay is known as the QVRH. In case the MVRH blower fails the the QVRH releases and trips the DJ through the relay Q-118. The transformer and its cooling equipment. The small vertical motor on top left is the MPH and the horizontal larger motor in the top centre is the MVRH and behind it is the oil cooling radiator.

Click for a larger view. One blower is provided for each of the rectifier blocks. As rectifiers are semiconductor devices, they are very sensitive to heat and hence must be cooled continously. The switching sequence of the MVSI blowers is setup in such a way that unless the blowers are runn 🔗 External reference