Advanced E-TEC Rigging

This document provides details on rigging an Evinrude E-TEC engine, specifically focusing on ICON gauges and ICON controls, with particular emphasis on NMEA 2000 integration and TRIM circuit specifications.

The rigging process for an Evinrude E-TEC engine involves several critical components and considerations to ensure optimal performance and functionality. The ICON gauges and controls are designed to provide a user-friendly interface for monitoring engine parameters and adjusting settings. These instruments utilize the NMEA 2000 protocol, which facilitates communication between various marine electronics, enhancing the overall integration of the engine with other onboard systems.

The NMEA 2000 network is a robust standard for marine electronics, allowing devices to communicate over a common data bus. When rigging the Evinrude E-TEC engine, it is essential to ensure that the ICON gauges are correctly connected to the NMEA 2000 backbone. This includes proper termination of the network with 120-ohm resistors at both ends and ensuring that all devices are powered appropriately. The gauges will display critical information such as engine speed, fuel level, and temperature, providing real-time data to the operator.

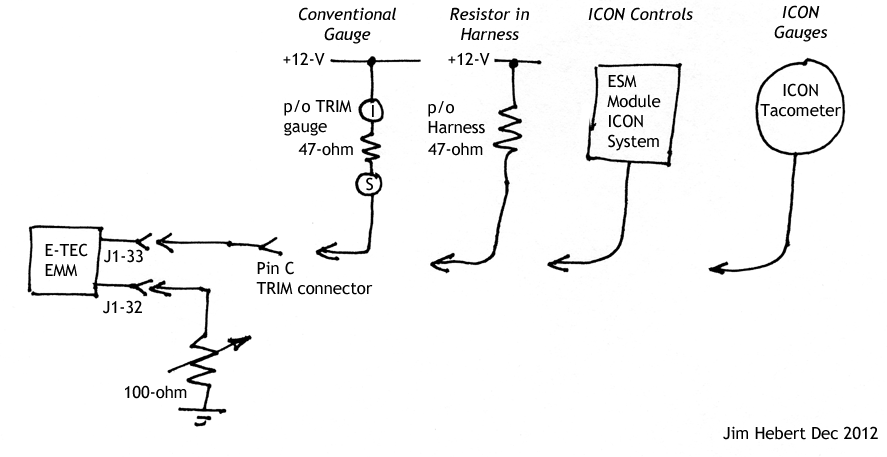

In addition to the NMEA 2000 setup, attention must be given to the TRIM circuit. The TRIM system adjusts the angle of the engine relative to the water surface, optimizing performance and fuel efficiency. The rigging process should include the installation of the TRIM sender, which communicates the trim position back to the ICON gauges. This feedback is crucial for the operator to make informed adjustments while operating the vessel.

Careful consideration of wiring and connections is vital to prevent signal interference and ensure reliable communication. All wiring should be routed away from sources of electromagnetic interference, and connectors should be weatherproofed to protect against the marine environment. Proper installation of the ICON controls, including throttle and shift mechanisms, is also necessary to achieve smooth operation and responsiveness.

Overall, rigging an Evinrude E-TEC engine with ICON gauges and controls requires meticulous attention to detail, particularly regarding NMEA 2000 integration and TRIM circuit functionality, to ensure a seamless and efficient operation on the water.Details of rigging an Evinrude E-TEC engine, particularly with ICON gauges and ICON controls, and with a special emphasis of NMEA-2000 details and TRIM circuit details. 🔗 External reference

The rigging process for an Evinrude E-TEC engine involves several critical components and considerations to ensure optimal performance and functionality. The ICON gauges and controls are designed to provide a user-friendly interface for monitoring engine parameters and adjusting settings. These instruments utilize the NMEA 2000 protocol, which facilitates communication between various marine electronics, enhancing the overall integration of the engine with other onboard systems.

The NMEA 2000 network is a robust standard for marine electronics, allowing devices to communicate over a common data bus. When rigging the Evinrude E-TEC engine, it is essential to ensure that the ICON gauges are correctly connected to the NMEA 2000 backbone. This includes proper termination of the network with 120-ohm resistors at both ends and ensuring that all devices are powered appropriately. The gauges will display critical information such as engine speed, fuel level, and temperature, providing real-time data to the operator.

In addition to the NMEA 2000 setup, attention must be given to the TRIM circuit. The TRIM system adjusts the angle of the engine relative to the water surface, optimizing performance and fuel efficiency. The rigging process should include the installation of the TRIM sender, which communicates the trim position back to the ICON gauges. This feedback is crucial for the operator to make informed adjustments while operating the vessel.

Careful consideration of wiring and connections is vital to prevent signal interference and ensure reliable communication. All wiring should be routed away from sources of electromagnetic interference, and connectors should be weatherproofed to protect against the marine environment. Proper installation of the ICON controls, including throttle and shift mechanisms, is also necessary to achieve smooth operation and responsiveness.

Overall, rigging an Evinrude E-TEC engine with ICON gauges and controls requires meticulous attention to detail, particularly regarding NMEA 2000 integration and TRIM circuit functionality, to ensure a seamless and efficient operation on the water.Details of rigging an Evinrude E-TEC engine, particularly with ICON gauges and ICON controls, and with a special emphasis of NMEA-2000 details and TRIM circuit details. 🔗 External reference