app note high voltage led applications

The applications outlined in this document pertain to driving high-power LED diodes. The circuits described can also be utilized in other applications with similar requirements, as long as they adhere to the specifications of the MLX10803. This is a conceptual overview, and in some instances, specific component values are not provided. Most of the applications mentioned have been implemented, and demonstration systems and components are available from Melexis. It is advised to contact the nearest sales office or representative for further information. Designing for high voltage is not a trivial task; significant caution must be exercised due to the high voltages involved. The examples provided must be meticulously designed and manufactured, as even minor errors can lead to severe consequences. These examples are not recommended for individuals lacking experience or training; they are intended for electrical and electronic engineers with relevant expertise in designing and constructing high-voltage circuits. The circuit board must be designed according to high-voltage standards. The circuits described exhibit high efficiency, with conversion efficiencies expected to reach 98-99%. This high efficiency simplifies thermal management considerations. It is important to note that when designing lamps rated at 100 watts or more, even a 1% loss results in an additional watt of heat. All forms of active current regulation introduce ripple on the regulated output, which can produce electromagnetic radiation (EMR) and lead to electromagnetic coupling with surrounding electronics (EMC). The MLX10803 and the applications detailed are engineered to minimize EMR. Additional precautions are necessary when designing the circuit board and the physical layout. Melexis does not guarantee the suitability of any of these circuits for EMI/EMC and EMR compliance with international standards. Compliance testing is recommended, and it is the user's responsibility to conduct such testing prior to distribution in specific countries and markets. High-voltage design is more complex than low-voltage applications using the MLX10803. It is strongly recommended to utilize the tools presented when developing high-voltage applications. These tools are essential for safety before connecting LED applications to the 110/220 V mains. The coil_calc_(x).zip file can be found on the Melexis website, which includes a self-instructive Microsoft Excel spreadsheet. This spreadsheet provides insights into the relationships between coils, currents, and sense values. While the underlying mathematics of the MLX10803 is complex, the spreadsheet simplifies this information, yielding approximate values that help understand the necessary component sizes and settings. After determining the values for coils, reference resistors, sense resistors, monostable timing, oscillator resistor values, and sense voltage settings using this tool, the next step is to implement these component values into the MLX10803 LED driver circuit and test them in an application. The LED supply can be decoupled from the circuit supply (VS/PWM) by removing the jumper on the EVB10803. Refer to the EVB10803 manual for instructions. When the LED supply is separated from the VS/PWM, the supply voltage to the LED is constrained by the parameters of the switching N-FET transistor and the flyback diode. This option should be used with extreme caution, and careful verification of the type of transistor and flyback diode present in the EVB10803 is essential before applying any voltage exceeding 32V.

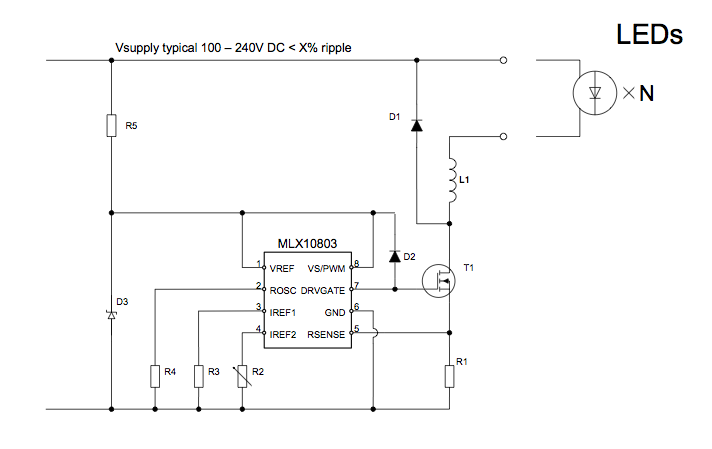

The MLX10803 is a versatile high-voltage LED driver IC designed for efficient operation in various lighting applications. It integrates features that allow for precise control of the current flowing through high-power LEDs, ensuring optimal performance and longevity. The architecture typically includes a PWM dimming capability, which enables brightness control without significant losses in efficiency.

For implementation, the circuit should incorporate a high-voltage power supply, suitable capacitors to filter and stabilize the input voltage, and inductors designed to handle the expected currents without saturating. The layout of the PCB is critical; it must adhere to high-voltage design rules to prevent arcing and ensure safety. This includes adequate spacing between traces, use of high-voltage rated components, and proper grounding practices to minimize noise and enhance reliability.

Thermal management is another crucial aspect. Since high-power LEDs can generate significant heat, the design must account for heat dissipation through the use of heat sinks or thermal vias, ensuring that the junction temperature of the LEDs remains within safe operating limits.

To mitigate electromagnetic interference (EMI), careful routing of signal traces and the inclusion of filtering components may be necessary. Ferrite beads and capacitors can be employed to suppress high-frequency noise generated by the switching action of the driver.

In summary, while the MLX10803 provides a robust solution for driving high-power LEDs, it necessitates a thorough understanding of high-voltage design principles, component selection, and PCB layout techniques to ensure a successful and safe implementation.The applications described in this document are applications for driving high power LED diodes. The described circuits can be applied on other applications with similar circumstances as well, in case they fall within the specifications of the MLX10803. This is a conceptual description and in some case no component values are given. The application s described in this document have in most cases been implemented. Demonstration systems and components are available at Melexis. Please contact our closest sales office or representative to learn more It is not a trivial task to design for high voltage, great care must to be taken in respect for the high voltages involved. The examples given in this document have to be carefully designed and fabricated. Slight errors can have devastating results. These examples are not recommended for the inexperienced or untrained lay people, it is intended for electrical and electronic engineers with relevant training and experience designing and building high voltage circuits.

The circuit board has to be design according to high voltage rules. Depending on the users The circuits described in this document have a very good efficiency, converting efficiencies up to 98-99% is to be expected! This makes the circuit design fairly simple in respect of thermal handling. Please remember that if you design lamps with up to 100 watt and more, even 1% loss generates 1 watt, and more of heat.

Every kind of active current regulation generates ripple on the regulated output, this ripple can generate electromagnetic radiation (EMR), resulting in electromagnetic coupling to the surrounding electronic (EMC). The MLX10803 and the applications described in this document are designed to minimize EMR. Additional care has to be taken when designing the circuit board and the physical application. Melexis makes no claims about the suitability of any of these circuits for EMI/EMC and EMR compliance against international regulations.

Compliance testing is recommended and it will fall to the user to conduct such testing prior to sale in specific countries and markets. High volt design is more demanding than making low voltage applications using MLX10803. We strongly recommend using the following presented tools when making high volt applications. Use these tools for your own safety, before you connect your LED application to the 110/220 V net. Find this program on the Melexis web site at, . Download the coil_calc_(x). zip file and use the Microsoft Excel spreadsheet included. The spreadsheet is self instructive. Play with it and get a feeling about the relation ship between coils, currents and sense values. The real mathematics behind the MLX10803 function is complicated, this sheet is a simplification. The tool gives only rough values, but it gives an impression what component sizes and settings are needed.

After finding out coil, reference resistors and sense resistor value, as well as mono flop time, oscillator resistor value and sense voltage settings with this tool, it is time to apply the component values to the MLX10803 LED driver circuit and try out the values in an application. The LED supply can be separated from the circuit supply (VS/PWM) by removing the jumper for that on the EVB10803.

See the manual for EVB10803 for instructions. When the supply to the LED is separated from the VS/PWM then the supply voltage to the LED is limited by the switching N-FET transistor parameters and the fly back diode. Please use this option with great care, and check carefully what type of transistor and fly back diode your EVB10803 is equipped with before applying any higher voltage than 32V.

🔗 External reference

The MLX10803 is a versatile high-voltage LED driver IC designed for efficient operation in various lighting applications. It integrates features that allow for precise control of the current flowing through high-power LEDs, ensuring optimal performance and longevity. The architecture typically includes a PWM dimming capability, which enables brightness control without significant losses in efficiency.

For implementation, the circuit should incorporate a high-voltage power supply, suitable capacitors to filter and stabilize the input voltage, and inductors designed to handle the expected currents without saturating. The layout of the PCB is critical; it must adhere to high-voltage design rules to prevent arcing and ensure safety. This includes adequate spacing between traces, use of high-voltage rated components, and proper grounding practices to minimize noise and enhance reliability.

Thermal management is another crucial aspect. Since high-power LEDs can generate significant heat, the design must account for heat dissipation through the use of heat sinks or thermal vias, ensuring that the junction temperature of the LEDs remains within safe operating limits.

To mitigate electromagnetic interference (EMI), careful routing of signal traces and the inclusion of filtering components may be necessary. Ferrite beads and capacitors can be employed to suppress high-frequency noise generated by the switching action of the driver.

In summary, while the MLX10803 provides a robust solution for driving high-power LEDs, it necessitates a thorough understanding of high-voltage design principles, component selection, and PCB layout techniques to ensure a successful and safe implementation.The applications described in this document are applications for driving high power LED diodes. The described circuits can be applied on other applications with similar circumstances as well, in case they fall within the specifications of the MLX10803. This is a conceptual description and in some case no component values are given. The application s described in this document have in most cases been implemented. Demonstration systems and components are available at Melexis. Please contact our closest sales office or representative to learn more It is not a trivial task to design for high voltage, great care must to be taken in respect for the high voltages involved. The examples given in this document have to be carefully designed and fabricated. Slight errors can have devastating results. These examples are not recommended for the inexperienced or untrained lay people, it is intended for electrical and electronic engineers with relevant training and experience designing and building high voltage circuits.

The circuit board has to be design according to high voltage rules. Depending on the users The circuits described in this document have a very good efficiency, converting efficiencies up to 98-99% is to be expected! This makes the circuit design fairly simple in respect of thermal handling. Please remember that if you design lamps with up to 100 watt and more, even 1% loss generates 1 watt, and more of heat.

Every kind of active current regulation generates ripple on the regulated output, this ripple can generate electromagnetic radiation (EMR), resulting in electromagnetic coupling to the surrounding electronic (EMC). The MLX10803 and the applications described in this document are designed to minimize EMR. Additional care has to be taken when designing the circuit board and the physical application. Melexis makes no claims about the suitability of any of these circuits for EMI/EMC and EMR compliance against international regulations.

Compliance testing is recommended and it will fall to the user to conduct such testing prior to sale in specific countries and markets. High volt design is more demanding than making low voltage applications using MLX10803. We strongly recommend using the following presented tools when making high volt applications. Use these tools for your own safety, before you connect your LED application to the 110/220 V net. Find this program on the Melexis web site at, . Download the coil_calc_(x). zip file and use the Microsoft Excel spreadsheet included. The spreadsheet is self instructive. Play with it and get a feeling about the relation ship between coils, currents and sense values. The real mathematics behind the MLX10803 function is complicated, this sheet is a simplification. The tool gives only rough values, but it gives an impression what component sizes and settings are needed.

After finding out coil, reference resistors and sense resistor value, as well as mono flop time, oscillator resistor value and sense voltage settings with this tool, it is time to apply the component values to the MLX10803 LED driver circuit and try out the values in an application. The LED supply can be separated from the circuit supply (VS/PWM) by removing the jumper for that on the EVB10803.

See the manual for EVB10803 for instructions. When the supply to the LED is separated from the VS/PWM then the supply voltage to the LED is limited by the switching N-FET transistor parameters and the fly back diode. Please use this option with great care, and check carefully what type of transistor and fly back diode your EVB10803 is equipped with before applying any higher voltage than 32V.

🔗 External reference