automatic low power emergancy light

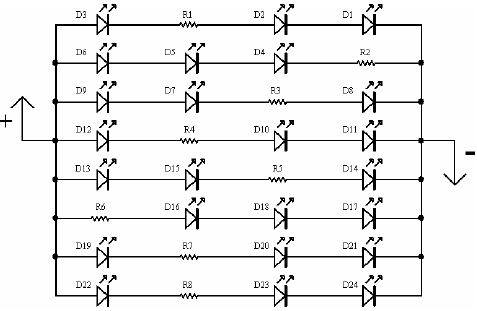

An emergency light system utilizing white LEDs, which provides several advantages: 1. It is highly bright due to the use of white LEDs. 2. The light activates automatically during a mains power failure and deactivates when mains power is restored. 3. It features a built-in battery charger that stops charging automatically when the battery is fully charged. The charger power supply section is based on the 3-terminal adjustable regulator IC LM317 (IC1), while the LED driver section utilizes the transistor BD140 (Q2). In the charger power supply section, input AC mains voltage is stepped down by transformer T1 to deliver 9V at 500mA to a bridge rectifier made up of diodes D1 through D4. A filter capacitor C1 is used to smooth out ripples. The unregulated DC voltage is supplied to pin 3 of IC1, which provides charging current through diode D5 and limiting resistor R15. The output voltage can be adjusted to provide the desired charging current by modifying preset P1. When the battery reaches a charge of 6.8V, diode D6 conducts, allowing the charging current from IC1 to flow to ground through transistor QT1, ceasing the battery charging process. When mains power is available, the base of Q2 remains high, preventing Q2 from conducting and keeping the LEDs off. Conversely, during a mains failure, the base of Q2 goes low, allowing it to conduct and illuminate all the LEDs. The mains power supply charges the battery while the LEDs remain off, as Q2 stays in a non-conducting state. In the event of mains failure, the charging section becomes inactive, and the battery supply powers the LEDs. The circuit should be assembled on a general-purpose PCB and enclosed in a cabinet with sufficient space for the battery and switches. The circuit has been tested with twelve 10mm white LEDs, although additional LEDs may be used as long as the total current consumption does not exceed 1.5A. The driver transistor Q2 can handle up to 1.5A with an appropriate heat sink.

The emergency light circuit operates efficiently by integrating multiple components to ensure reliable performance during power outages. The LM317 regulator serves as the backbone of the charging circuit, allowing for voltage adjustments that cater to different battery specifications. The use of a transformer to step down the AC voltage is critical, as it ensures that the subsequent components receive the correct voltage levels for optimal operation.

The bridge rectifier converts the AC voltage into DC, which is essential for charging the battery and powering the LEDs. The inclusion of a filter capacitor (C1) is crucial in smoothing out any voltage fluctuations, thereby protecting sensitive components from potential damage. The current limiting resistor (R15) and diode (D5) work in tandem to regulate the charging current, preventing overcharging and extending the battery's lifespan.

The functionality of the system is further enhanced by the transistor Q2, which acts as a switch to control the LED illumination based on mains availability. This automatic switching mechanism is vital for emergency lighting, ensuring that the LEDs only activate when needed. The circuit's design allows for scalability, accommodating additional LEDs as long as the total current remains within safe limits. Proper thermal management for Q2 is also a key consideration, as excessive heat can lead to component failure.

Overall, this emergency light circuit is a robust solution for providing illumination during power outages, with features that ensure safety, reliability, and ease of use. The careful selection of components and thoughtful design considerations contribute to a highly functional and efficient lighting solution.A white-LED-based emergency light that offers the following advantages. 1-It is highly bright due to the use of white LEDs. 2-The light turns on automatically when mains supply fails, and turns off when mains power resumes. 3-It has its own battery charger. When the battery is fully charged, charging stops automatically. The charger power supply section is built around 3-terminal adjustable regulator IC LM317 (IC1), while the LED driver section is built around transistor BD140 (Q2). In the charger power supply section, an input AC main is stepped down by T1 to deliver 9V, 500mA to the bridge rectifier, which comprises diodes D1 through D4.

Filter capacitor C1 eliminates ripples. Unregulated DC voltage is fed to input pin 3 of IC1 and provides charging current through D5 and limiting resistor R15. By adjusting preset P1, the output voltage can be adjusted to deliver the required charging current. When the battery gets charged to 6. 8V, D6 conducts and charging current from IC1 finds a path throughQT1 to ground and it stops charging of the battery.

When mains power is available, the base of Q2 remains high and Q2 does not conduct. Thus LEDs are off. On the other hand, when mains fails, the base of Q2 becomes low and it conducts. This makes all the LEDs glow. The mains power supply, when available, charges the battery and keeps the LEDs off as Q2 remains cut-off. During mains failure, the charging section stops working and the B1 supply makes the LEDs glow. Assemble the circuit on a general-purpose PCB and enclose in a cabinet with enough space for battery and switches.

We have tested the circuit with twelve 10mm white LEDs. You can use more LEDs provided the total current consumption does not exceed 1. 5A. Driver transistor Q2 can deliver up to 1. 5A with proper heat-sink arrangement. 🔗 External reference

The emergency light circuit operates efficiently by integrating multiple components to ensure reliable performance during power outages. The LM317 regulator serves as the backbone of the charging circuit, allowing for voltage adjustments that cater to different battery specifications. The use of a transformer to step down the AC voltage is critical, as it ensures that the subsequent components receive the correct voltage levels for optimal operation.

The bridge rectifier converts the AC voltage into DC, which is essential for charging the battery and powering the LEDs. The inclusion of a filter capacitor (C1) is crucial in smoothing out any voltage fluctuations, thereby protecting sensitive components from potential damage. The current limiting resistor (R15) and diode (D5) work in tandem to regulate the charging current, preventing overcharging and extending the battery's lifespan.

The functionality of the system is further enhanced by the transistor Q2, which acts as a switch to control the LED illumination based on mains availability. This automatic switching mechanism is vital for emergency lighting, ensuring that the LEDs only activate when needed. The circuit's design allows for scalability, accommodating additional LEDs as long as the total current remains within safe limits. Proper thermal management for Q2 is also a key consideration, as excessive heat can lead to component failure.

Overall, this emergency light circuit is a robust solution for providing illumination during power outages, with features that ensure safety, reliability, and ease of use. The careful selection of components and thoughtful design considerations contribute to a highly functional and efficient lighting solution.A white-LED-based emergency light that offers the following advantages. 1-It is highly bright due to the use of white LEDs. 2-The light turns on automatically when mains supply fails, and turns off when mains power resumes. 3-It has its own battery charger. When the battery is fully charged, charging stops automatically. The charger power supply section is built around 3-terminal adjustable regulator IC LM317 (IC1), while the LED driver section is built around transistor BD140 (Q2). In the charger power supply section, an input AC main is stepped down by T1 to deliver 9V, 500mA to the bridge rectifier, which comprises diodes D1 through D4.

Filter capacitor C1 eliminates ripples. Unregulated DC voltage is fed to input pin 3 of IC1 and provides charging current through D5 and limiting resistor R15. By adjusting preset P1, the output voltage can be adjusted to deliver the required charging current. When the battery gets charged to 6. 8V, D6 conducts and charging current from IC1 finds a path throughQT1 to ground and it stops charging of the battery.

When mains power is available, the base of Q2 remains high and Q2 does not conduct. Thus LEDs are off. On the other hand, when mains fails, the base of Q2 becomes low and it conducts. This makes all the LEDs glow. The mains power supply, when available, charges the battery and keeps the LEDs off as Q2 remains cut-off. During mains failure, the charging section stops working and the B1 supply makes the LEDs glow. Assemble the circuit on a general-purpose PCB and enclose in a cabinet with enough space for battery and switches.

We have tested the circuit with twelve 10mm white LEDs. You can use more LEDs provided the total current consumption does not exceed 1. 5A. Driver transistor Q2 can deliver up to 1. 5A with proper heat-sink arrangement. 🔗 External reference