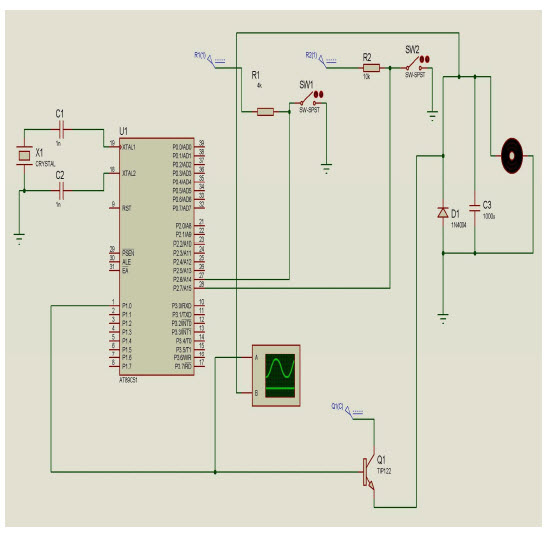

Bidirectional H-Bridge DC-Motor Motion Controller

Combining armature resistance cancellation through positive current feedback with a motion-reversing H-bridge circuit topology introduces an innovative approach to DC servo motor speed control.

The integration of armature resistance cancellation in DC servo motors is a significant advancement in enhancing performance and efficiency. This technique utilizes positive current feedback to compensate for the voltage drop across the armature resistance, which typically reduces the effective voltage supplied to the motor. By effectively canceling this resistance, the system can maintain higher torque and improve response times during operation.

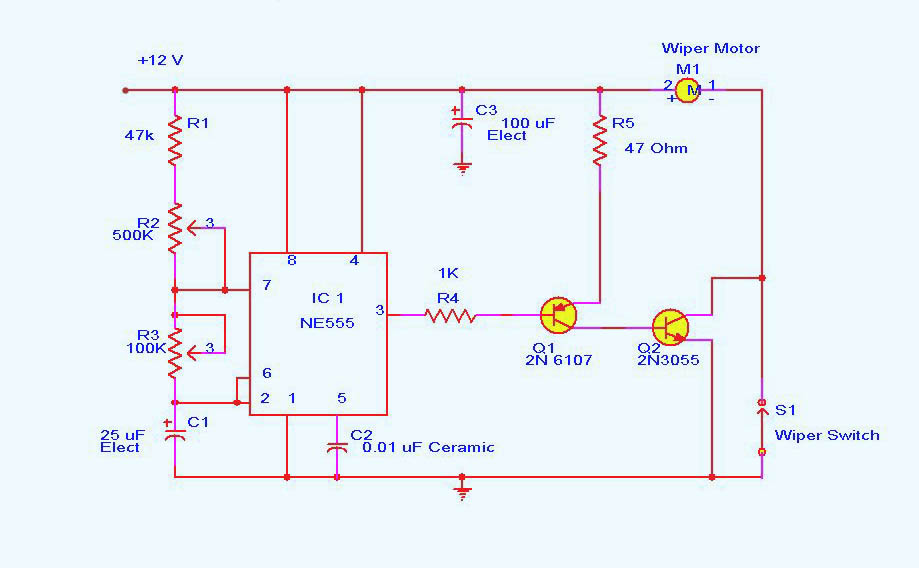

In conjunction with this technique, the motion-reversing H-bridge circuit topology plays a critical role in the control of the motor's direction and speed. An H-bridge configuration enables the reversal of current flow through the motor, allowing for bi-directional control. The H-bridge consists of four switches (transistors or MOSFETs), arranged in a bridge configuration. By selectively turning on pairs of switches, the voltage across the motor can be controlled to either drive it forward or reverse.

The combination of these two elements allows for precise speed control of the DC servo motor. The positive current feedback ensures that the motor operates efficiently across various load conditions, while the H-bridge provides the flexibility to change direction instantly. This sophisticated control mechanism is particularly beneficial in applications requiring rapid changes in motion, such as robotics, CNC machinery, and automated systems.

In summary, the synergy between armature resistance cancellation and the H-bridge circuit topology results in a robust, efficient, and versatile DC servo motor control system, capable of delivering high performance in demanding applications.Combining armature resistance cancellation (via positive current feedback) with a motion-reversing H-bridge circuit topology offers a new twist in dc servo motor speed control 🔗 External reference

The integration of armature resistance cancellation in DC servo motors is a significant advancement in enhancing performance and efficiency. This technique utilizes positive current feedback to compensate for the voltage drop across the armature resistance, which typically reduces the effective voltage supplied to the motor. By effectively canceling this resistance, the system can maintain higher torque and improve response times during operation.

In conjunction with this technique, the motion-reversing H-bridge circuit topology plays a critical role in the control of the motor's direction and speed. An H-bridge configuration enables the reversal of current flow through the motor, allowing for bi-directional control. The H-bridge consists of four switches (transistors or MOSFETs), arranged in a bridge configuration. By selectively turning on pairs of switches, the voltage across the motor can be controlled to either drive it forward or reverse.

The combination of these two elements allows for precise speed control of the DC servo motor. The positive current feedback ensures that the motor operates efficiently across various load conditions, while the H-bridge provides the flexibility to change direction instantly. This sophisticated control mechanism is particularly beneficial in applications requiring rapid changes in motion, such as robotics, CNC machinery, and automated systems.

In summary, the synergy between armature resistance cancellation and the H-bridge circuit topology results in a robust, efficient, and versatile DC servo motor control system, capable of delivering high performance in demanding applications.Combining armature resistance cancellation (via positive current feedback) with a motion-reversing H-bridge circuit topology offers a new twist in dc servo motor speed control 🔗 External reference

.jpg)